2

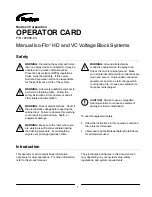

Startup

The startup procedure assumes the system was left

full of coating material after the last shutdown. For

daily startup, see Figure 1 and do the following:

1. Make sure the electrostatic voltage is off.

2. Turn on compressed air to the Iso-Flo system (5).

Verify that the setting is 5

−

8 bar (80

−

120 psi).

3. Turn on the fluid inlet pressure. Verify that the

setting is 5

−

10.3 bar (80

−

150 psi).

4. Turn on the electrostatic voltage. Verify that the

setting is 60 kV or less.

Refer to

Operation

for the procedures to follow to

begin spraying.

1300374A

1

5

6

3

4

2

Figure 1 Basic System Components

1. Spray device

2. Fluid hose

3. Toggle valve

4. Fluid pressure adjustment knob

5. Iso-Flo HD system

6. Electrostatic power supply

Operation

See Figure 1. Squeezing the trigger on the spray

device (1) activates the Iso-Flo system and spraying

can begin. Before spraying, check the fluid pressure,

atomizing air, and fan pattern and adjust as needed.

NOTE:

The Iso-Flo system supplies about 40 oz of

coating material continuously. In most situations

there are enough pauses between parts to allow the

system to refill itself. If your operation does not

provide these pauses, release the trigger on the

spray device completely for 5

−

15 seconds. Do this

every 2

−

5 minutes (depending on the spray gun flow

rate).

NOTE:

For Iso-Flo VC system, the supply volume

can be adjusted to less than the full 40 oz capacity.

Fluid Pressure Adjustment

To adjust the fluid output pressure and flow rate, see

Figure 1 and do the following:

1. Turn the fluid pressure adjustment knob (4) in

small increments.

2. Squeeze the trigger on the spray device (1) and

check the spray pattern. Continue adjusting the

pressure as needed.

NOTE:

The fluid pressure should be 0.7

−

2.1 bar

(10

−

30 psi). If you reach a setting outside of this

range, try selecting a different fluid tip size. For

details on selecting a fluid tip, refer to the instructions

provided with your spray gun.

Atomizing Air Adjustment

Use the externally supplied air regulator to adjust the

atomizing air until you achieve the required

atomization. To maximize electrostatics, select the

lowest possible pressure at which you can achieve

good atomization.

NOTE:

The atomizing air setting should be

2.1

−

3.5 bar (30

−

50 psi). Electrostatics will not

activate below 2.1 bar (30 psi).

Fan Pattern Adjustment

Refer to the instructions provided with your spray gun

for information on adjusting the fan pattern.