Installation

3-3

2001 Nordson Corporation

All rights reserved

334 627B

Issued 3/01

Manual 31-46

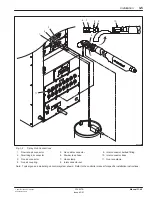

Perform the following steps to install the gun cable, powder feed hose,

and air tubing.

WARNING: All electrically conductive equipment in the spray

area must be grounded. Ungrounded or poorly grounded

equipment can store an electrostatic charge which can give

personnel a severe shock or arc and cause a fire or explosion.

NOTE: The spray gun is shipped with gun cable and air tubing

extensions connected to the back of the spray gun. This allows the gun

cable and air tubing connections to be made without having to

disassemble the spray gun.

NOTE: To increase powder flow and keep distribution of air in the

powder even, keep the powder feed hose as short as possible. The

powder feed hose should be no longer than 16 m (50 ft) long.

NOTE: Two inlet connector barbed fittings are shipped with the gun: a

1

/

2

-in. fitting (attached to the spray gun), and an 11-mm fitting (shipped

loose). Select the correct fitting based on the size of feed hose in your

system.

1. Install the powder feed hose.

a. Unscrew the inlet connector nut (8) and remove the nut and

barbed fitting (9) from the inlet connector body (10).

b. Slide the supplied hose clamp (7) onto the powder feed hose (6).

c. Install the powder feed hose over the barbed inlet fitting. Secure

the feed hose with the hose clamp.

d. Install the barbed fitting into the inlet connector body on the gun.

Tighten the nut to secure the barbed fitting to the connector body.

e. Connect the other end of the powder feed hose to the powder

pump.

f. If using the gun in a quick color change system, install the second

feed hose onto another barbed fitting/nut assembly following

steps b–e. Push the second feed hose assembly onto one of the

fittings on the hose support bracket.

2. Connections

Summary of Contents for Sure Coat Series

Page 8: ...Safety 1 0 2000 Nordson Corporation All rights reserved Issued 7 00 S1EN 03 SF Powder 6 ...

Page 28: ...Operation 4 0 2001 Nordson Corporation All rights reserved 334 627B Issued 3 01 Manual 31 46 ...

Page 34: ...Operation 4 6 2001 Nordson Corporation All rights reserved 334 627B Issued 3 01 Manual 31 46 ...

Page 46: ...Repair 6 0 2001 Nordson Corporation All rights reserved 334 627B Issued 3 01 Manual 31 46 ...

Page 56: ...Parts 7 0 2001 Nordson Corporation All rights reserved 334 627B Issued 3 01 Manual 31 46 ...

Page 66: ......