Troubleshooting

5-2

2001 Nordson Corporation

All rights reserved

334 627B

Issued 3/01

Manual 31-46

Problem

Possible Cause

Corrective Action

1. Uneven pattern, unsteady

or inadequate powder

flow

(contd)

Improper fluidization of powder in

hopper

Increase the fluidizing air pressure.

If the problem persists, remove the

powder from the hopper and inspect the

fluidizing plate. Clean or replace the

fluidizing plate if it is contaminated.

Damp powder

1. Check the powder supply, air filters,

and dryer.

2. Replace the powder supply if

contaminated.

2.

Voids in powder pattern

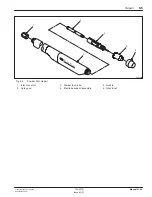

Worn nozzle

Remove and inspect the nozzle.

Replace it if it is worn.

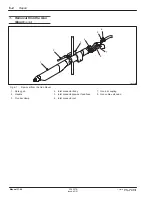

Plugged powder path

Remove the nozzle parts, inlet

connector, and powder feed hose from

the gun and clean them.

3.

Loss of wrap, poor

transfer efficiency

NOTE: Before checking possible

causes, check the error code on the

controller and perform the error code

corrective action in the controller

manual.

Low electrostatic voltage

Increase the electrostatic voltage.

Poor electrode connection

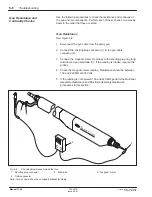

Perform the

Electrode Support

Assembly Continuity procedure in this

section.

Poorly grounded parts

Check the conveyor chain, rollers, and

part hangers for powder buildup. The

resistance between the parts and

ground must be 1 megohm or less. For

best results, 500 ohms or less is

recommended.

2. Troubleshooting Charts

(contd)

Summary of Contents for Sure Coat Series

Page 8: ...Safety 1 0 2000 Nordson Corporation All rights reserved Issued 7 00 S1EN 03 SF Powder 6 ...

Page 28: ...Operation 4 0 2001 Nordson Corporation All rights reserved 334 627B Issued 3 01 Manual 31 46 ...

Page 34: ...Operation 4 6 2001 Nordson Corporation All rights reserved 334 627B Issued 3 01 Manual 31 46 ...

Page 46: ...Repair 6 0 2001 Nordson Corporation All rights reserved 334 627B Issued 3 01 Manual 31 46 ...

Page 56: ...Parts 7 0 2001 Nordson Corporation All rights reserved 334 627B Issued 3 01 Manual 31 46 ...

Page 66: ......