14

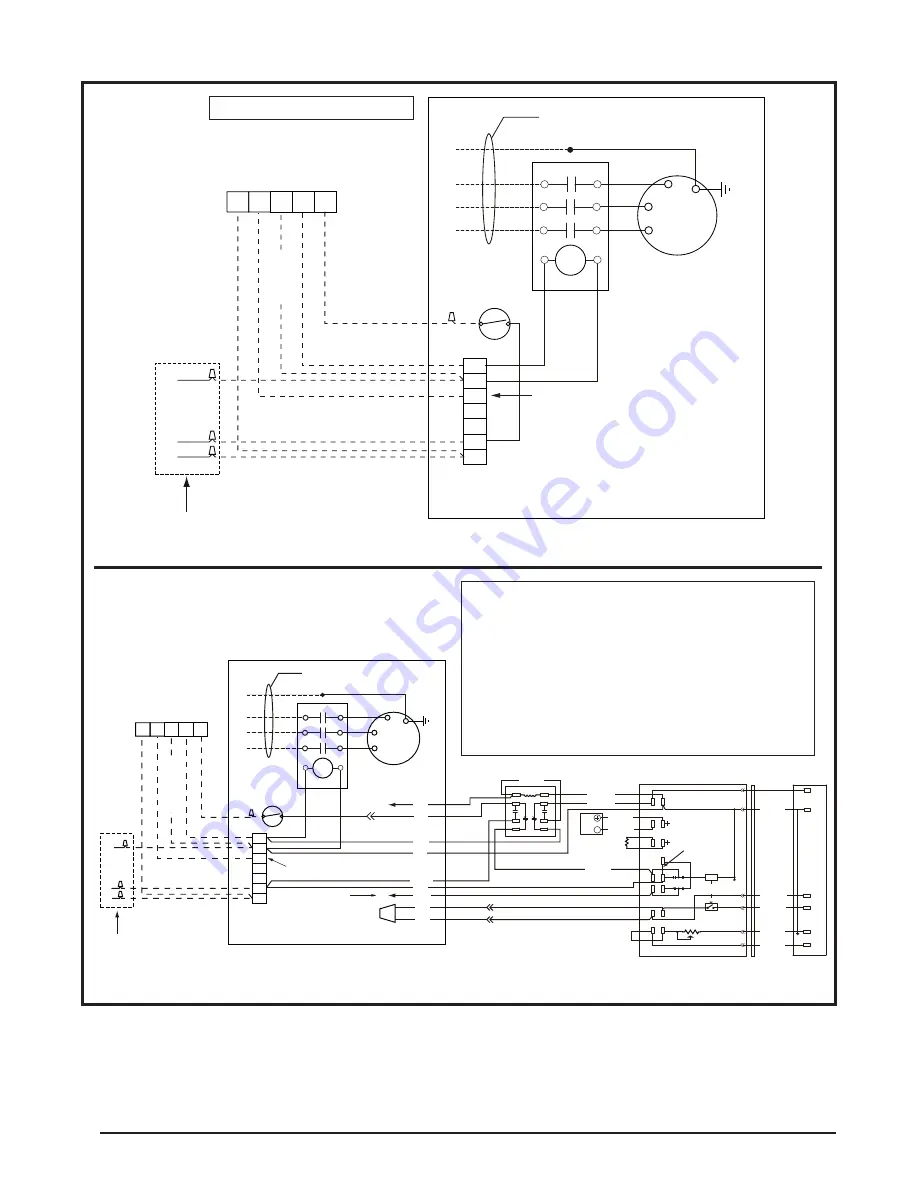

Figure 7. Typical Air conditioner Thermostat Connections

BLOWER

MOTOR

GND

TO FIELD

SUPPLIED DISCONNECT

SINGLE STAGE

HEAT/COOL THERMOSTAT

OUTDOOR

SECTION

FREEZESTAT

SINGLE STAGE HEAT/COOL THERMOSTAT- NO ECONOMIZER

AIR HANDLER

SECTION

TERMINAL

BOARD

G

C

W2

W1

O

Y

R

C

Y

R

R

C G Y

W

L1

L2

L3

NOTE: C &W2 to be connected to electric heat.

See Note

BLACK

BLACK

BROWN

GREEN

OPTIONAL

BLOWER

MOTER

GND

TO FIELD

SUPPLIED DISCONNECT

SINGLE STAGE

HEAT/COOL

THERMOSTAT

OUTDOOR

SECTION

FREEZESTAT

SINGLE STAGE HEAT/COOL THERMOSTAT- WITH ECONOMIZER

AIR HANDLER

SECTION

TERMINAL

BOARD

G

C

W2

W1

O

Y

R

C

Y

R

R

C G Y

W

L1

L2

L3

s

C7400A

B

Y1

OPTIONAL

ECONOMIZER

W7459A

C7150

M.A.S.

TB-11

M7415A

T

T1MA

MIN.

POT.

P1

P

TR1

TR

Y2

S

TR 1

TR

o

S

1

3

2

4

T

P

T1

2K

JUMPER

WIRE

5

P1

r

1S

1S

A

B

7

9

4

6

1

3

BLU-14”

YEL-18”

GRY-90”

GRN

GRY

YEL

BLK

ORN

RED

RED

WHITE

BLUE

VIO-14”

GRN-18”

GRN-18”

RED-12”

GRY-12”

BLK-12”

BLU-12”

BLK-12”

NOTES:

1. C & W2 to be connected to electric heat.

2. Remove BLACK wire from air handler low voltage terminal board

Y terminal and connect to YELLOW wire from economizer.

3. 2nd Stage refrigerant cooling with optional economizer installed. A 2

stage thermostat is required for simultaneous operation of the economizer

and refrigerant system. Connect Y2 from 2 stage thermostat to BLUE

wire from economizer. If installing an economizer in this unit, refer to the

Economizer installation instructions for proper set up and operation.

4. Heat Pump Economizer Relay. For heat pump applications only, connect B

from thermostat to GREY wire from Economizer. Required for proper operation

of an economizer (optional) in the heat pump Heating mode. If installing an

economizer in this unit, refer to the Economizer installation instructions for

proper set up and operation.

Note 4

Note 2

Note 1

Note 3

BLACK

BLACK

GREEN

OPTIONAL