17

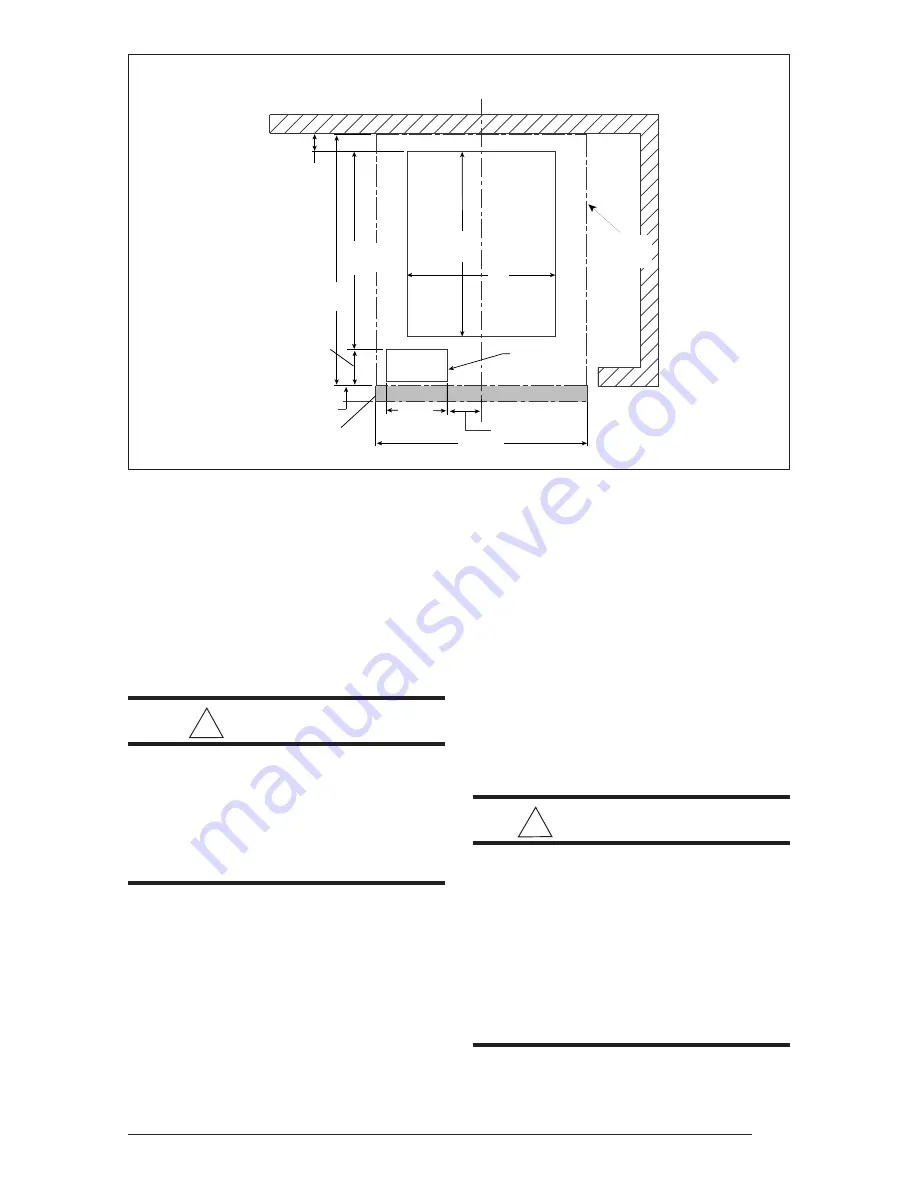

5.

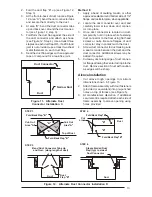

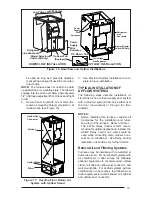

Position furnace onto coil cabinet and se-

cure with two or more fasteners.

6.

Use optional upflow duct connector or field

supplied connector to attach furnace to

overhead supply duct (see Figure 17).

ELECTRICAL SYSTEM

INSTALLATION

!

WARNING:

To avoid the risk of electrical shock,

personal injury or death, disconnect

all electrical power to the unit before

performing any maintenance or

service. The unit may have more than

one electrical power supply.

Codes, Specifications, and

Requirements

The wiring, installation, and electrical hookup of

this furnace must comply with the National

Electrical Code (or the Canadian Electrical

Code) and all regulations of local authorities

having jurisdiction. See Table 6a & 6b for mini-

mum circuit ampacity, maximum over-current

protection, and recommended wire size. See

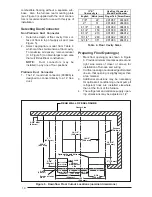

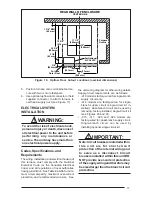

1 3/4" MIN

(45 mm)

23 3/4"

(604 mm)

3/4"

(20 mm)

20"

(508 mm)

17 1/2"

(445 mm)

14"

(356 mm)

5 3/4"

(147 mm)

3 1/8"

(80 mm)

3"

(73 mm)

Furnace

Outer Door

For Optional

A/C Or H/P

REAR WALL OF ENCLOSURE

CENTER LINE

Furnace

Outline

18 5/8"

(474 mm)

Figure 19. Upflow Floor Cutout Locations (nominal dimensions)

the unit wiring diagram for other wiring details.

Supply-circuit requirements are as follows:

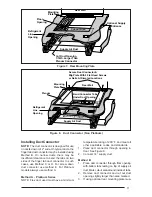

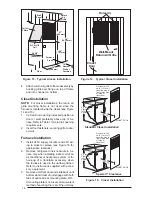

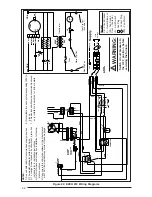

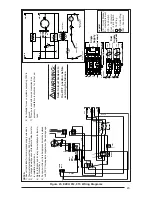

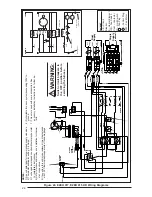

• -010 model is factory-wired for single-branch

supply circuit only.

• -012 models are factory-wired for single-

branch supply circuit (single-circuit kit in-

stalled). Dual-branch circuit can be used by

removing factory-installed single-circuit kit

(see Figures 20 and 21).

• -015, -017, -020 and -023 models are

factory-wired for dual-branch supply circuit.

Single-branch circuit can be used by

installing optional single-circuit kit .

!

IMPORTANT:

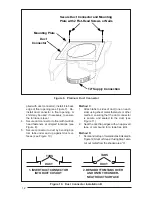

Note: Circuit breakers installed within

t h i s u n i t a r e f o r s h o r t - c i r c u i t

protection of the internal wiring and

to serve as a disconnect. Circuit

breakers installed within this unit DO

NOT provide over-current protection

of the supply wiring and therefore may

be sized larger than the branch circuit

protection.