9

• The quality of outdoor air must also be considered. Be

sure that the combustion air intake is not located near

a source of solvent fumes or other chemicals which can

cause corrosion of the furnace combustion system.

• Route piping as direct as possible between the furnace

and the outdoors.

• If a Direct Vent (2-pipe) system is used, the combustion

air intake and the vent exhaust must be located in the

same atmospheric pressure zone. This means both pipes

must exit the building through the same portion of exterior

wall or roof as shown in Figure 30 (page 34). Vent piping

must be sloped upwards 1/4” per foot in the direction

from the furnace to the terminal. This is to ensure that

any condensate fl ows back to the condensate disposal

system.

• Piping must be mechanically supported so that its weight

does not bear on the furnace. Pipe supports must be

installed a minimum of every 5 feet along the vent run to

ensure no displacement after installation. Supports may

be at shorter intervals if necessary to ensure that there

are no sagging sections that can trap condensate. It is

recommended to install couplings along the vent pipe,

on either side of the exterior wall (Figure 30). These

couplings may be required by local code.

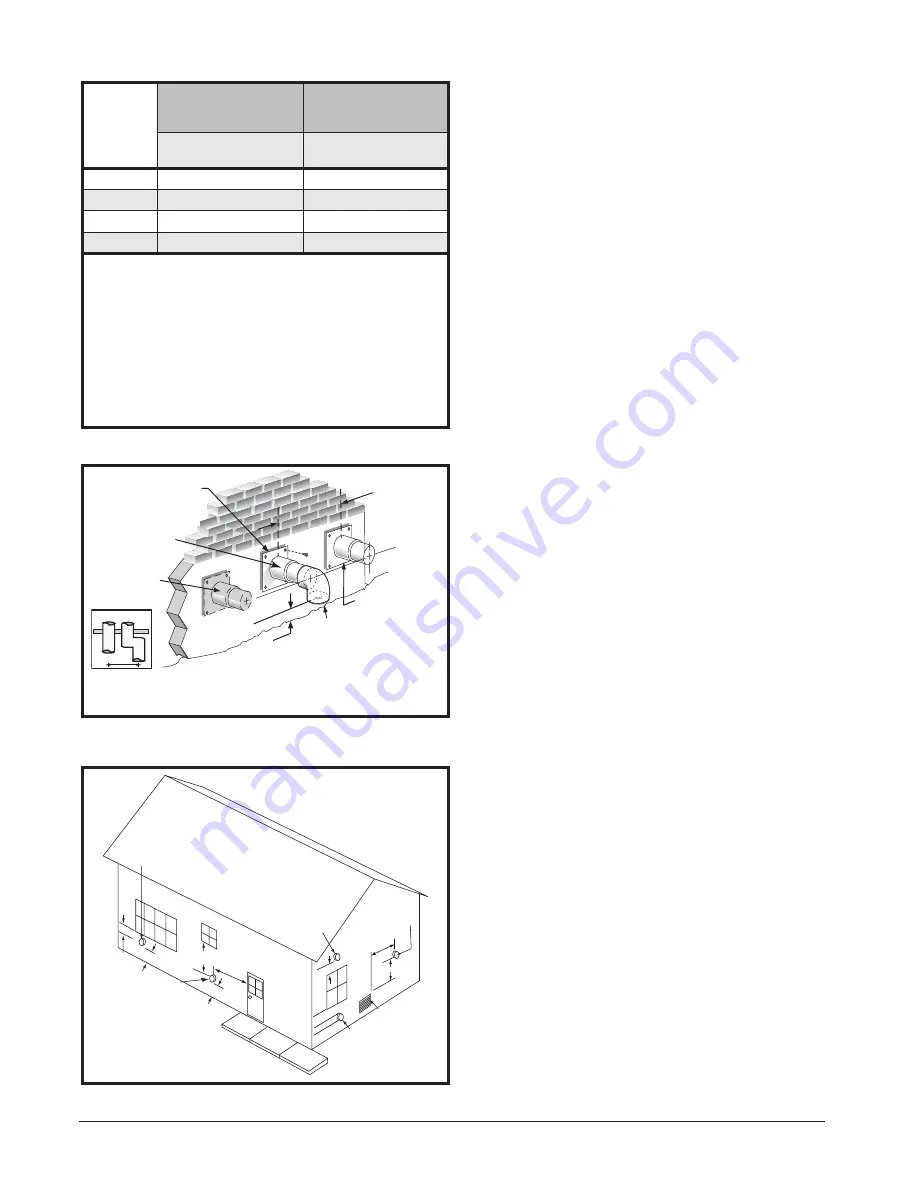

Outdoor Terminations - Horizontal Venting

Vent termination clearances must be consistent with the

IFGC and in accordance with these instructions.

• Vent and combustion air intake terminations shall be

installed as shown in Figures 6 & 7.

• All minimum clearances (Figure 7) must be maintained

to protect building materials from degradation by fl ue

gases.

• Vent and combustion air intake terminations must

be located to ensure proper furnace operation and

conformance to applicable codes. Figure 7 lists the

distances from the vent termination to windows and

building air intakes.

• For optimal performance, vent the furnace through a

wall that experiences the least exposure to winds

.

• Do not install the vent terminal such that exhaust is

directed into window wells, stairwells, under decks or into

alcoves or similar recessed areas, and do not terminate

above any public walkways.

• If venting horizontally, a side wall vent kit is available

according to the pipe diameter size of the installation (kit

# 904349).

Please follow the instructions provided

with the kit.

• Concentric vent termination kits are available for use

with these furnaces (kit # 904176).

Please follow the

instructions provided with the kit.

• When the vent pipe must exit an exterior wall close to

the grade or expected snow level where it is not possible

to obtain clearances shown in Figure 6, a riser may be

provided as shown in Figure 8 (page 10). Insulation is

required to prevent freezing of this section of pipe. See

vent freezing protection information below.

12 in.

12 in.

4 ft.

Note 2

Mechanical

draft vent

terminal

Direct vent

terminal

50,000 Btuh

or less

Forced

Air Inlet

Direct vent

terminal -

more than

50,000 Btuh

Mechanical

draft vent

terminal

Mechanical

draft vent

terminal

Less

than 10 ft.

3 ft.

NOTES:

1. All dimensions shown are minimum

requirements.

2. Exterior vent terminations must be located at

least 12 In above the maximum expected snow level.

Note 2

Note 2

9 In.

4ft.

Figure 7 Vent Locations

12" Min.

to Maxim

um

Expected Sno

w Le

vel

Typical Both Pipes

36" max.

8" min.

Exhaust V

ent

Right Side Option

Mounting Kit

Faceplate Secured

to Wall with Screws

Typical Both Pipes

Combustion

Air Inlet

Inlet Exhaust

Both Sides

Exhaust Vent

Left Side Option

90°

Elbo

w

Figure 6. Exhaust and Combustion Air

Pipe Clearances

Table 2. Vent Pipe Lengths (FT.)

FURNACE

MODELS

SINGLE VENT PIPE

with 1 long

radius elbow*

DUAL VENT PIPE

with 1 long radius

elbow on each pipe*

OUTLET

3” Diameter

INLET/OUTLET

3” Diameter

XC046

80

80

XC061

80

80

XC076

80

80

XC102

80

80

*NOTES:

1. These lengths apply for elevations from sea level to 2,000 ft. For

higher elevations decrease vent pipe lengths by 8% per 1,000

ft. of altitude.

2. When calculating vent lengths, subtract 2.5 ft. for each additional

2" elbow and 3.5 ft. for each additional 3" elbow. Two 45° elbows

are equivalent to one 90° elbow. One short radius elbow is

equivalent to two long radius elbows. Do not include termination

elbows in calculation of vent length.

3. The length of pipe needed between the inducer and the fi nish

fl ange is 7 3/4”.