11

Outdoor Terminations - Horizontal Venting

Vent and combustion air intake terminations shall

be installed as depicted in

accordance with these instructions:

• Vent termination clearances must be consistent with the

NFGC, ANSI 2223.1/NFPA 54 and/or the CSA B149.1,

Natural Gas and Propane Installation Code.

• All minimum clearances must be maintained to protect

building materials from degradation by flue gases as

shown in

.

• Vent and combustion air intake terminations must

be located to ensure proper furnace operation and

conformance to applicable codes. The minimum distance

from any door, open window, or air gravity inlet is 1ft.

below, 1ft. horizontally, or 1ft. above. In Canada, CSA

B149.1 takes precedence over these instructions.

lists the necessary distances from the

vent termination to windows and building air intakes.

• The vent termination shall be located at least 4 ft.

horizontally from any electric meter, gas meter, regulator

and any relief equipment. These distances apply ONLY

to U.S. installations. In Canada, the Canadian Fuel Gas

Code takes precedence over these instructions.

• Do not install the vent terminal such that exhaust is

directed into window wells, stairwells, under decks

or into alcoves or similar recessed areas, and do not

terminate above any public walkways.

• If venting horizontally, a side wall vent kit is available

according to the pipe diameter size of the installation.

For 2 inch pipe use side wall vent kit #904617, and

for 3 inch pipe use kit #904349.

Please follow the

instructions provided with the kit.

• When the vent pipe must exit an exterior wall close to

the grade or expected snow level where it is not possible

to obtain clearances shown in

, a riser may be

. Insulation

is required to prevent freezing of this section of pipe.

For vent freezing protection, see

.

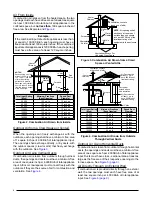

Figure 7

12” min.

to maximum

expected sno

w lev

el

(both pipes)

90° Elbo

w

Exhaust v

ent

option B

Exhaust v

ent

option A

Mounting kit f

aceplate

secured to w

all with scre

ws

(both pipes)

Comb

ustion

air inlet

Exhaust v

ent

option C

18” Min.

36” Max.

8” Min.

36” Max.

(all positions)

Figure 7.

Inlet & Exhaust Pipe Clearances

WARNING:

The combustion air vent and exhaust vent must

be configured as shown in Figure 9. Improper

vent terminations can cause the recirculation of

flue gases which may result in furnace vibration.

In severe cases, the furnace will cycle, due to

the intermittent contact between the flame and

the flame sensor. If you notice these oscillations

occurring, check the vent configuration to make

sure the exhaust vent does not have a 90 degree

termination.

• For optimal performance, vent the furnace through a

wall that experiences the least exposure to winter winds.

• Termination kits consist of two face plates and an

insulating gasket to seal the exterior surface.

• The hole in the wall must be sized closely to the diameter

of the pipe.

• The pipe that penetrates the wall should be long enough

that it can be held in place by standard close fitting

couplings.

• Face plates are secured to both sides of the wall by the

couplings, and the gasket is retained against the wall

by the exterior face plate.

• Face plates must be fastened to the wall. Exterior face

plates must be flashed to prevent water infiltration.

If termination kits are not used, these requirements

must be followed:

• The hole size cut through the exterior wall is smaller

than the outside diameter of the couplings.

• The vent pipe extends through the wall approximately

1" and the gap between the wall and pipe is sealed.

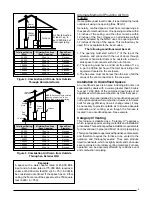

Figure 8. Vent Locations

12 in.

12 in.

4 ft.

Note 3

Less

than

10 ft.

3 ft.

NOTES:

1. All dimensions shown are minimum requirements.

2. Exterior vent terminations must be located at

least 12” above the maximum expected snow level.

3. Mechanical draft vent terminal

4. Direct vent terminal - more than 50,000 Btuh.

5. Direct vent terminal - less than 50,000 Btuh.

9 in.

4ft.

Forced

Air Inlet

Notes

2 & 4

Note 3

Notes

2 & 3

Notes

2 & 5

Figure 8

Summary of Contents for M4RC-072D-35C

Page 47: ...47...