30

ELECTRICAL SHOCK, FIRE OR EXPLOSION

HAZARD

Failure to follow safety warnings exactly could

result in serious injury or property damage.

Improper servicing could result in dangerous

operation, serious injury, death or property

damage.

• Before servicing, disconnect all electrical

power to furnace.

• When servicing controls, label all wires prior

to disconnecting. Reconnect wires correctly.

• Verify proper operation after servicing.”

WARNING:

RISQUE DE CHOC ÉLECTRIQUE, D’INCENDIE

OU D’EXPLOSION

Le non-respect des avertissements de sécurité

pourrait entraîner

un fonctionnement dangereux

de l’appareil, des blessures graves, la mort ou

des dommages matériels.

Un entretein incorrect pourrait entraîner un

fonctionnement dangereux de l’appareil, des

blessures graves, la mort ou des dommages

matériels

• Couper toute alimentation électrique au

générateur d’air chaud avant de prodéder

aux travaux d’entretein.

• Au moment de l’entretien des commandes,

étiquetez tous les fils avant de les débrancher.

S’assurer de les raccorder correctement.

• S’assurer que l’appareil fonctionne

adéquatement aprés l’entretien.

AVERTISSEMENT

:

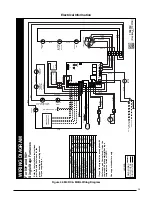

ELECTRICAL WIRING

• Electrical connections must be in compliance with all

applicable local codes with the current revision of the

National Electric Code (ANSI/NFPA 70).

• For Canadian installations the electrical connections

and grounding shall comply with the current Canadian

Electrical Code (CSA C22.1 and/or local codes).

IMPORTANT NOTE:

If replacing any of the original wires supplied with the

furnace, the replacement wire must be copper wiring

and have a temperature rating of at least 105°F (40°C).

For electrical specifications, refer to the furnace

nameplate or

2. Check all gas connections for leaks with a soap and

water solution. If the solution bubbles there is a gas

leak which must be corrected.

3. Turn on all electrical power to the furnace.

4. Turn the gas valve ON/OFF knob (

position.

5. Start the furnace by adjusting the thermostat 5 degrees

above room temperature.

6. Check the furnace for proper ignition and operating

sequence (See

).

7. After ignition, visually inspect the burner assembly to

verify that the flame is drawn directly into the center of

the heat exchanger tube.

NOTES:

In a properly adjusted burner assembly, the flame color

should be blue with some light yellow streaks near the

outer portions of the flame.

The ignitor may not ignite the gas until all of the air is bled

from the gas line. If the ignition control locks out, adjust

the thermostat to its lowest setting and wait one minute.

Adjust the thermostat 5 degrees above room temperature

and the ignitor will try again to ignite the main burners.

This process may have to be repeated several times

before the burners will ignite. Once the burners are lit,

check all gas connections for leaks again with the soap

and water solution.

WARNING:

Do not alter or remove the original rating plate

from the furnace.

8. Affix the conversion warning label (P/N 703935) to the

outside of the unit door and the conversion information

label (P/N 703942) near the rating plate inside the control

area.

9. Affix the gas conversion label from the conversion kit

on the gas valve. Each label should be prominent and

visible after installation.

10. Reinstall the appliance door.

11. Run the appliance through three complete cycles to

assure proper operation.

Summary of Contents for M4RC-072D-35C

Page 47: ...47...