10

Table 1

Vent Pipe Material

Vent and combustion air pipe and fittings must be one of

the following materials in the list and must conform to the

indicated ANSI/ASTM standards. Cement must conform

to ASTM Standard D2564 for PVC and Standard D2235

for ABS. PVC Primer must meet standard ASTM F656.

When joining PVC piping to ABS, use PVC solvent cement.

(See procedure specified in ASTM Standard D3138).

In Canada, all plastic vent pipes and fittings including

any cement, cleaners, or primers must be certified as a

system to ULC S636. However, this requirement does not

apply to the finish flanges or piping internal to the furnace.

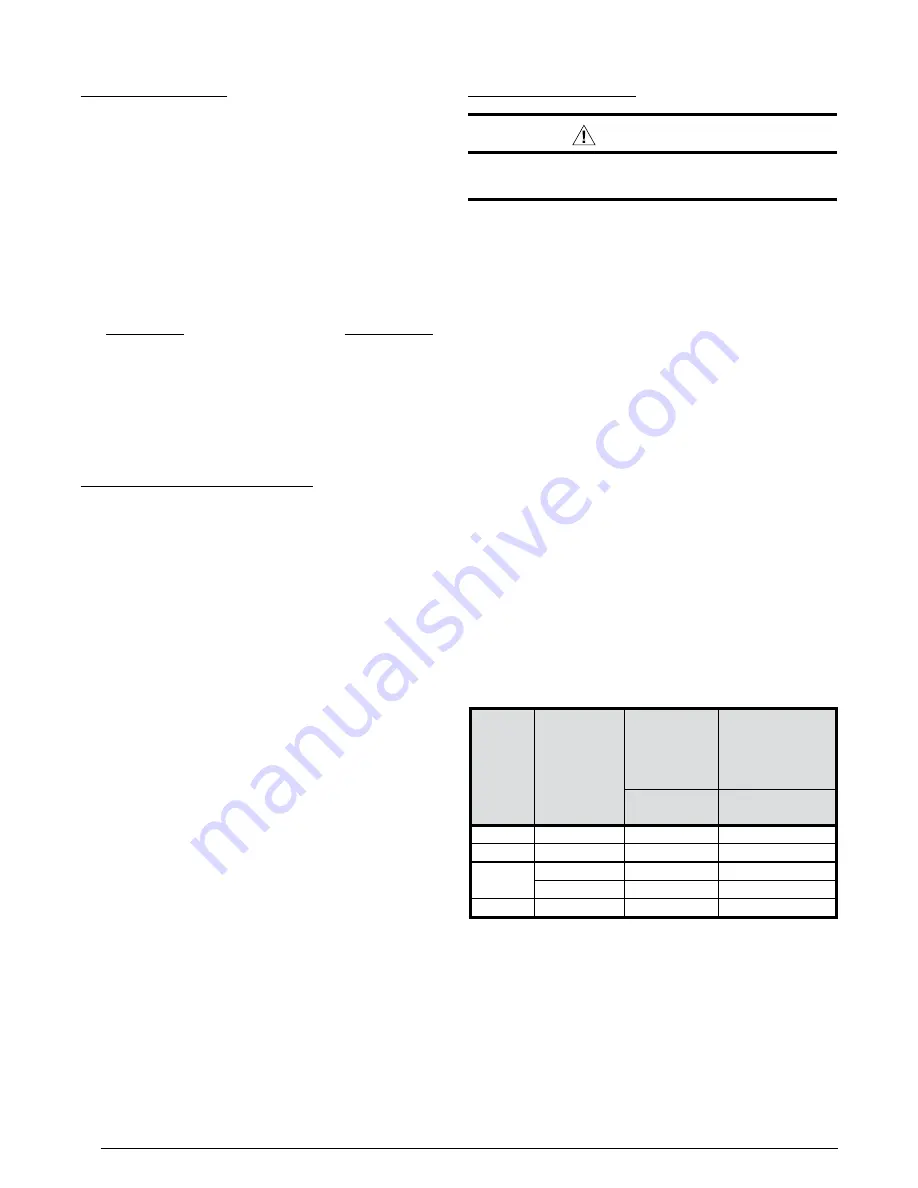

FURNACE

(BTU)

FURNACE

INSTALLATION

SINGLE PIPE

LENGTH (FT.)

with 1 long

radius elbow

†

DUAL VENT PIPE

LENGTH (FT.)

with 1 long radius

elbow on each pipe

†

OUTLET

3” Diameter

INLET/OUTLET

3” Diameter

54,000

Upflow

90

90

72,000

Upflow

90

90

90,000

Upflow

90

90

Downflow

90

90

108,000

Upflow

90

90

†

NOTES:

• The length of 2” pipe needed between the inducer and the exit hole

(top of cabinet) is 8 3/4” for upflow models and 16” for downflow

models.

• Subtract 2.5 ft. for each additional 2 inch long radius elbow, 5 ft. for

each additional 2 inch short radius elbow, 3.5 ft. for each additional

3 inch long radius elbow, and 7 ft. for each additional 3 inch short

radius elbow. Subtract 8ft for each 3” tee.

• Two 45 degree elbows are equivalent to one 90 degree elbow.

• This table applies for elevations from sea level to 2,000 ft. For higher

elevations, decrease pipe lengths by 8% per 1,000 ft of altitude.

Table 1. Vent Pipe Lengths

Materials

Standards

SCHEDULE 40PVC ............................... D1785

PVC-DWV .............................................. D2665

SDR-21 & SDR-26 ................................. D2241

ABS-DWV .............................................. D2661

SCHEDULE 40 ABS .............................. F628

FOAM / CELLULAR CORE PVC ........... F891

Vent Pipe Installation

CAUTION:

Combustion air must not be drawn from a

corrosive atmosphere.

This furnace has been certified for installation with zero

clearance between vent piping and combustible surfaces.

However, it is good practice to allow space for convenience

in installation and service.

• The quality of outdoor air must also be considered. Be

sure that the combustion air intake is not located near

a source of solvent fumes or other chemicals which can

cause corrosion of the furnace combustion system. See

list of substances on

.

• Route piping as direct as possible between the furnace

and the outdoors. Horizontal piping from inducer to

the flue pipe must be sloped 1/4” per foot to ensure

condensate flows towards the drain tee or PVC trap.

Longer vent runs require larger pipe diameters. Refer

to the Inducer & Venting Options section on

for additional information..

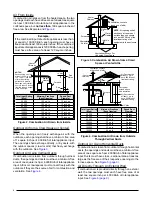

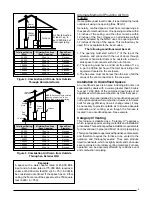

• The combustion air intake and the vent exhaust must

be located in the same atmospheric pressure zone.

This means both pipes must exit the building through

the same portion of exterior wall or roof as shown in

,

&

.

• Piping must be mechanically supported so that its

weight does not bear on the furnace. Supports must

be at intervals no greater than 5 ft. Supports may be at

shorter intervals if necessary to ensure that there are

no sagging sections that can trap condensate.

Vent Pipe Length & Diameter

In order for the furnace to operate properly, the combustion

air and vent piping must not be excessively restrictive.

• The venting system should be designed to have the

minimum number of elbows or turns.

• Transition to the final vent diameter should be done as

close to the furnace outlet as practical.

• Always use the same size or a larger pipe for combustion

air that is used for the exhaust vent.

specifies the maximum allowable pipe length for

vent and combustion air for a furnace of known input rate,

when installed with piping of selected diameter and number

of elbows. Before using the table, the furnace input rate,

the centerline length and the number of elbows on each

pipe must be known.

When estimating the length of vent runs, consideration

must be made to the effect of elbows and other fittings.

This is conveniently handled using the idea of “equivalent

length”. This means the fittings are assigned a linear

length that accounts for the pressure drop they will cause.

For example: a 2” diameter, long radius elbow is worth

the equivalent of 2.5 feet of linear run. A 90 degree tee

is worth 7 ft.

The equivalent lengths of tees and various elbows are

listed in

. Measure the linear length of your vent

run and then add in the equivalent length of each fitting.

The total length, including the equivalent fitting lengths,

must be less than the maximum length in the table.

Summary of Contents for M4RC-072D-35C

Page 47: ...47...