13

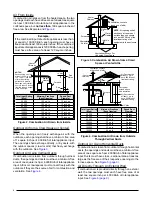

Existing Installations

When an existing furnace is removed from a vent system

serving other appliances, the existing vent system may

not be sized properly to vent the remaining appliances

(Example: water heater). An improperly sized venting

system can result in the formation of condensate, leakage,

or spillage. The existing vent system should be checked

to make sure it is in compliance with NFGC, ANSI Z223.1,

or CAN/CGA B149 and must be brought into compliance

before installing the furnace.

NOTE: If replacing an existing furnace, it is possible you

will encounter an existing plastic venting system that is

subject to a Consumer Product Safety Commission recall.

The pipes involved in the recall are High Temperature

Plastic Vent (HTPV).

If your venting system contains

these pipes

DO NOT reuse this venting system!

This

recall does not apply to other plastic vent pipes, such

as white PVC or CPVC. Check for details on the CPSC

website or call their toll-free number (800) 758-3688.

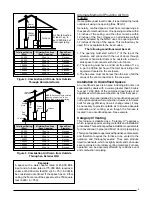

Concentric Vent Termination

A concentric vent termination (kit # 904953) is approved

for use with these furnaces. Please follow the installation

instructions provided with the kit for proper installation.

Condensate Disposal

The method for disposing of condensate varies according

to local codes. Consult your local code or authority having

jurisdiction. Neutralizer kit P/N 902377 is available for

use with this furnace.

Please follow the instructions

provided with the kit.

This furnace has multiple options for positioning the vent

pipe as described in the Inducer & Venting Options section

(

). Each of the condensate drain lines must be

J-trapped using field supplied parts.

After the condensate lines are J-trapped, they may be

combined together when routed to the drain. Avoid areas

where condensate drainage may cause problems by

dropping onto planters, patios, etc.

NOTE: Industry research studies indicate that when

condensate is routed to an active drain, household

detergents, etc., buffer its acidity. If the drain is not actively

used or if codes require, obtain a neutralizer kit (usually

contains limestone). Proper drains and connections to the

condensate tubing are required as NORDYNE cannot be

held responsible for water leakage which occurs due to

loose hose connections or improperly sealed drain line

pipes.

CIRCULATING AIR REQUIREMENTS

WARNING:

Do not allow combustion products to enter the

circulating air supply. Failure to prevent the

circulation of combustion products into the

living space can create potentially hazardous

conditions including carbon monoxide

poisoning that could result in personal injury

or death.

All return ductwork must be secured to

the furnace with sheet metal screws. For

installations in confined spaces, all return

ductwork must be adequately sealed. When

return air is provided through the bottom of the

furnace, the joint between the furnace and the

return air plenum must be air tight.

The surface that the furnace is mounted on must

provide sound physical support of the furnace

with no gaps, cracks or sagging between the

furnace and the floor or platform.

Return air and circulating air ductwork must

not be connected to any other heat producing

device such as a fireplace insert, stove, etc. This

may result in fire, explosion, carbon monoxide

poisoning, personal injury, or property damage.

Plenums & Air Ducts

• Plenums and air ducts must be installed in accordance

with the Standard for the Installation of Air Conditioning

and Ventilating Systems (NFPA No. 90A) or the

Standard for the Installation of Warm Air Heating and

Air Conditioning Systems (NFPA No. 90B).

•

and temperature rise data for each furnace input rate.

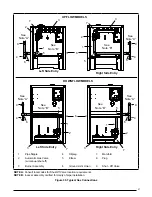

NOTE: If the maximum airflow is 1,600 CFM or more,

it is recommended that two openings be used for return

air on upflow furnaces. Downflow furnaces can only use

one return opening.

• It is recommended that the outlet duct contain a

removable access panel. The opening should be

accessible when the furnace is installed in service and

shall be of a size that smoke or refelcted light may be

observed inside the casing to indicate the presence of

leaks in the heat exchanger. The cover for the opening

shall be attached in such a manner as to prevent leaks.

• If outside air is used as return air to the furnace for

ventilation or to improve indoor air quality, the system

must be designed so that the return air is not less than

60° F (15° C) during operation. If a combination of indoor

and outdoor air is used, the ducts and damper system

must be designed so that the return air supply to the

Summary of Contents for M4RC-072D-35C

Page 47: ...47...