14

furnace is equal to the return air supply under normal,

indoor return air applications.

• When a cooling system is installed which uses the

furnace blower to provide airflow over the indoor coil,

the coil must be installed downstream (on the outlet

side) of the furnace or in parallel with the furnace.

• If a cooling system is installed in parallel with the

furnace, a damper must be installed to prevent chilled

air from entering the furnace and condensing on the heat

exchanger. If a manually operated damper is installed,

it must be designed so that the furnace will not operate

when the damper is in the cooling position or when in

heating position, the cooling system is inoperable.

• It is good practice to seal all connections and joints

with industrial grade sealing tape or liquid sealant.

Requirements for sealing ductwork vary from region

to region. Consult with local codes for requirements

specific to your area.

Return Air Connections

In applications where the supply ducts carry heated air to

areas outside the space where the furnace is installed,

the return air must be delivered to the furnace by duct(s)

secured to the furnace casing, running full size and without

interruption.

• Upflow furnaces draw the return air from the base of

the furnace. A stand or return air duct must be supplied

to the furnace to provide the required return air.

• Downflow models draw the return air from the top of

the furnace. The minimum required clearance to the top

of the furnace is detailed on the furnace rating plate.

Additional clearance may be required depending upon

filter accessibility.

For each U.S.A. application, the home manufacturer

shall comply with all of the following conditions to have

acceptable return air systems for closet installed forced

air heating appliances:

• Regardless of the location, the return air opening into the

closet shall not be less than specified in the appliance’s

listing.

• Means shall be provided to prevent inadvertent closure

by a flat object placed over the return air opening when

it is located in the floor of the closet (versus the vertical

front or side wall).

• The cross-sectional area of the return duct system

leading into the closet shall not be less than 390 in

2

.

• The total free area of openings in the floor or ceiling

registers serving the return air duct system must be at

least 352 in

2

. At least one register should be located

where it is not likely to be covered by carpeting, boxes

and other objects.

• Materials located in the return duct system must have a

flame spread classification of 200 or less. This includes

a closet door if the furnace is in a closet.

• Noncombustible pans having 1" upturned flanges are

located beneath openings in a floor duct system.

• Wiring materials located in the return duct system shall

conform to Articles 300-22 of the National Electrical

Code (ANSI C1/NFPA-70).

• Gas piping is not run in or through the return duct system.

• Test the negative pressure in the closet with the air-

circulating fan operating at high speed and the closet

closed. The negative pressure is to be no more negative

than minus 0.05 inch water column.

• Air conditioning systems may require more duct, register

and open louver area to obtain necessary airflow. Use

NORDYNE’s certiduct program to determine proper

duct size for A/C.

• For floor return systems, the manufactured home

manufacturer shall affix a prominent marking on or

near the appliance where it can be easily read when

the closet door is open. The marking shall read:

CAUTION:

HAZARD OF ASPHYXIATION:

Do not cover or

restrict return air opening.

Supply Air Connections

For proper air distribution, the supply duct system must be

designed so that the static pressure measured external

to the furnace does not exceed the listed static pressure

rating shown on the furnace rating plate.

The supply

air must be delivered to the heated space by duct(s)

secured to the furnace casing, running full size and

without interruption.

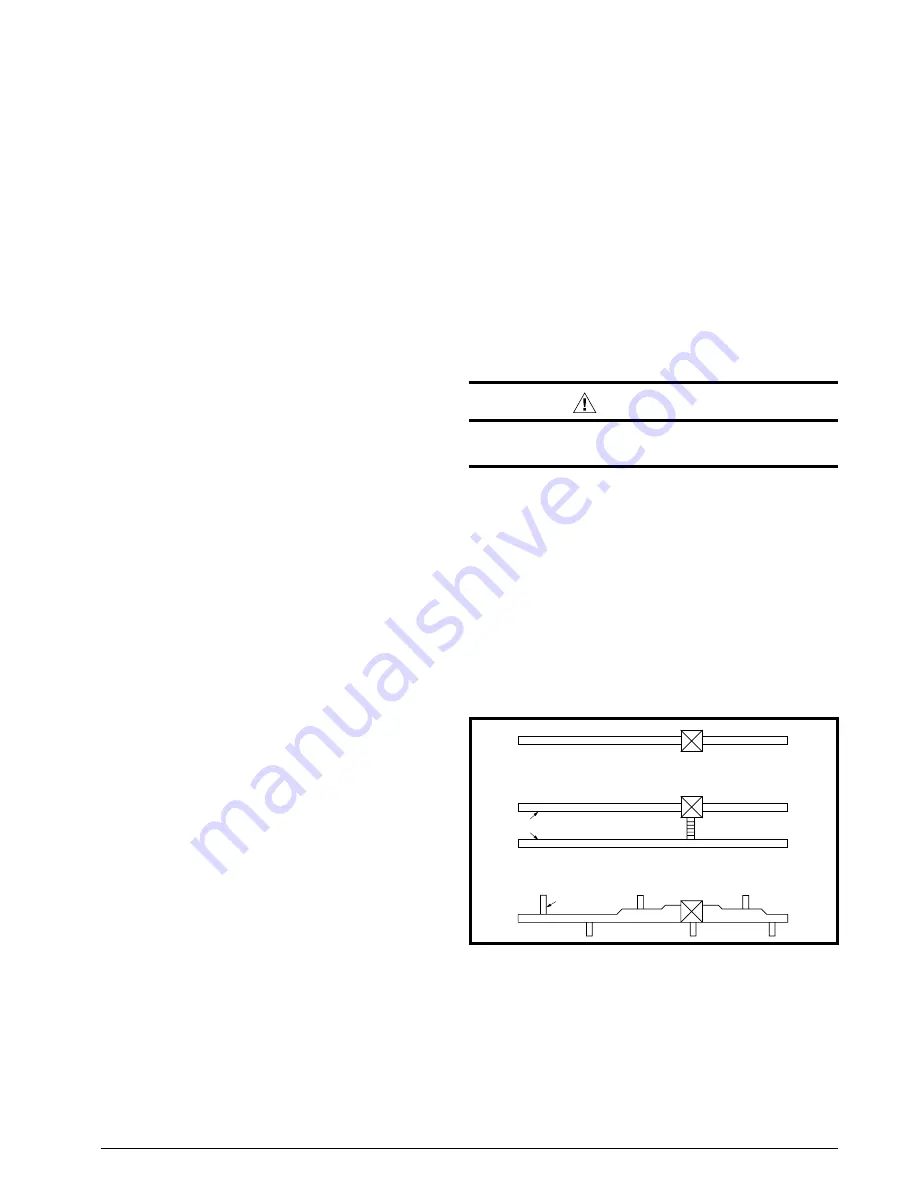

Three typical distribution systems are shown in

.

The location, size, and number of registers should be

selected on the basis of best air distribution and floor

plan of the home.

Figure 11

A Single trunk duct

B

Dual trunk duct

w/crossover connector

C

Transition duct

w/branches

Figure 11.

Typical Supply Duct System

Acoustical Treatments

Damping ducts, flexible vibration isolators, or pleated

media-style filters on the return air inlet of the furnace

may be used to reduce the transmission of equipment

noise eminating from the furnace. These treatments can

produce a quieter installation, particularly in the heated

space. However, they can increase the pressure drop in

Summary of Contents for M4RC-072D-35C

Page 47: ...47...