16

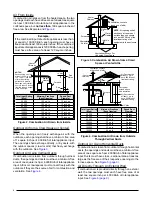

Figure 12

NOTES:

With reducer installed: Opening to duct is 10-1/4” x 13-1/4”.

With reducer removed: Opening to duct is 13-1/4” x 13-1/4”.

REDUCER

(See Notes)

FELT-SEAL

SPACERS

DUCT CONNECTOR TABS

FIBERGLASS

INSULATION

Figure 12. Duct Connector

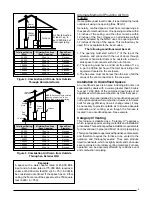

Figure 13

REAR WALL OF CLOSET OR ALCOVE

10”

13 1/4”

13 1/4”

Floor Cut-Out for

Duct Connector

FURNACE CABINET OUTLINE

FUEL

LINE

HOLE

ALT. FUEL

LINE HOLE

C

L

C

L

Figure 13.

Floor Cutout Dimensions

Downflow Furnace Installation

NOTE: These Installation procedures are suggested for

typical furnace installations. Since all installations are

different from each other, the sequence of instructions

may differ from the actual installation.

WARNING:

The furnace must not be installed directly on

carpeting, tile, or any combustible material other

than wood flooring.

The *RL series gas furnace is certified for use on wood

flooring or supports, but must be installed on a special

duct connector (

). This factory supplied accessory

must be installed in the floor cavity and attached to the

supply air duct before the downflow furnace is installed.

The depth of the floor cavity (shown as “X” in

)

will determine the duct connector size to use. Several

connector sizes are listed in

.

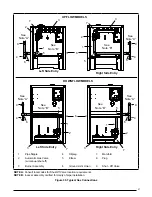

Table 3

If Floor Cavity

(“X”) is:

Duct Connector

Type & Part Number

Finger Tab

Screw Down

7/8” (22)

901987A

904008

2” (51)

901988A

904009

4-1/4” (108)

901989A

904010

6-1/4” (159)

901990A

904011

8-1/4” (210)

901991A

904012

10-1/4” (260)

901992A

904013

12-1/4” (311)

901993A

904014

NOTE: Dimensions shown as Inches (Millimeter)

Table 3.

Duct Connector Sizes

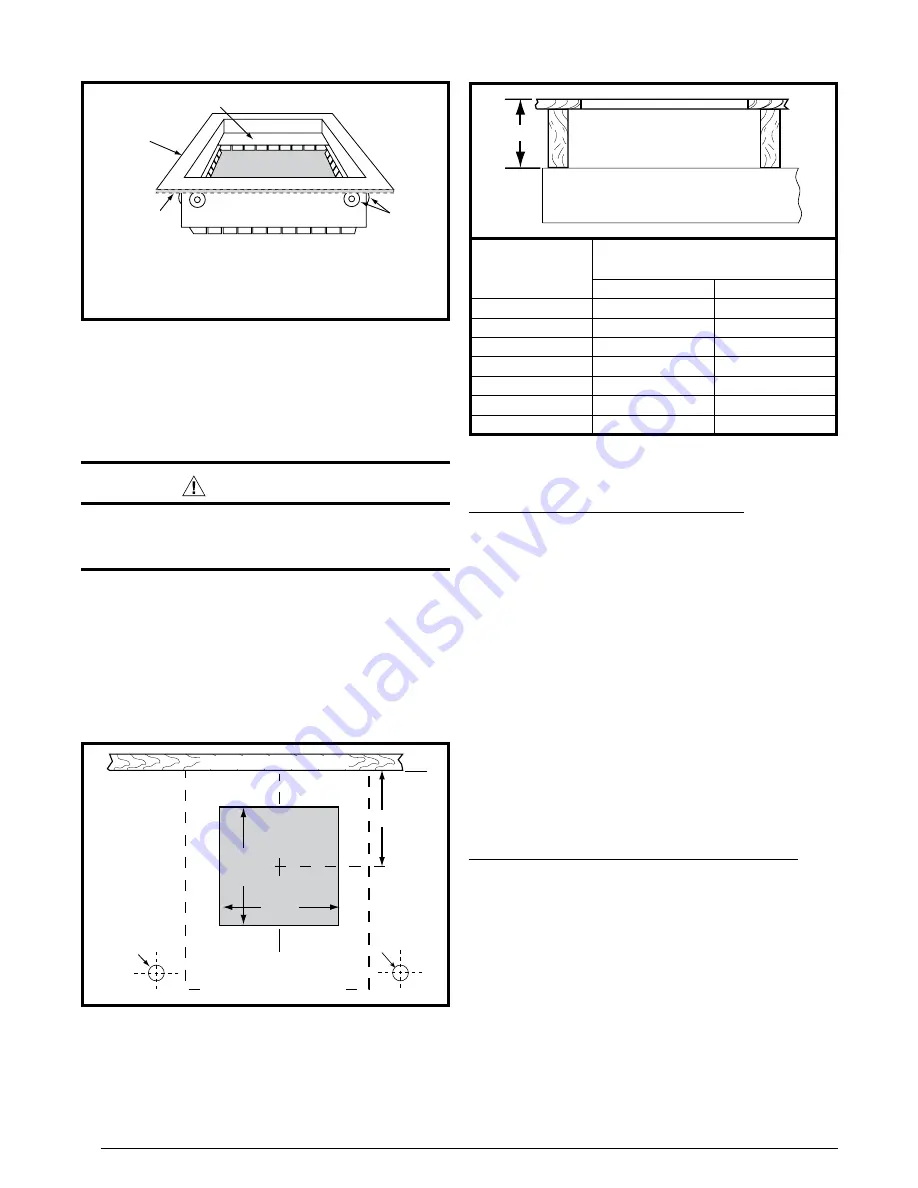

“X”

FLOOR OPENING

FLOOR CAVITY

SUPPLY AIR DUCT

Locating & Cutting Floor Openings

IMPORTANT NOTE:

Cut-outs in the floor, must be carefully located to

avoid misalignment of the furnace. To locate standard

ducts, see

.

1. Measure from the rear wall or alcove and mark the

centerline of the cut-out on the floor. Using the centerline

as a starting point, draw the rest of the duct cut-out to

the dimensions shown in

.

2. Cut out the floor opening to within 1” of the actual cutout

drawn.

3. Measure from the top of the floor down to the top of the

supply air duct to obtain the depth of the floor cavity.

NOTE: The depth of the floor cavity shown as “X” in

will determine the correct duct connector.

4. Determine which duct connector to use from the table.

5. Measure and drill gas hole and cut out for cooling coil

(if applicable).

Installing Finger Tabbed Duct Connectors

The standard duct connector is designed for use on ducts

12” in width. However ducts narrower than 12” may not

allow sufficient clearances for this type of installation.

See Narrow Duct Attachment for an alternate installation

method.

1. Center the duct connector in the floor opening with

bottom tabs resting on top of the supply air duct.

2. Mark the cut-out area on the supply air duct by tracing

around the connector tabs (

) of

the duct connector.

3. Remove the duct connector and cut out the marked

area of the supply air duct 1/16” larger the actual cutout

drawn.

Summary of Contents for M4RC-072D-35C

Page 47: ...47...