31

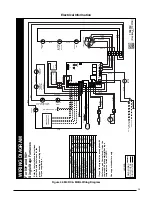

Line Voltage Wiring

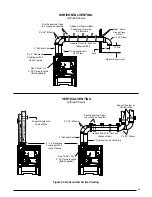

It is recommended that the line voltage (115 VAC) to

the furnace be supplied from a dedicated branch circuit

containing the correct fuse or circuit breaker for the furnace

as listed in

.

IMPORTANT NOTES:

• An electrical disconnect must be installed readily

accessible from and located within sight of the

furnace. See

diagram label inside of the control door. Any other

wiring methods must be acceptable to authority

having jurisdiction.

• Proper line voltage polarity must be maintained in

order for the control system to operate correctly.

Verify the incoming neutral line is connected to the

white wire and the incoming “hot” line is connected

to the black wire. The furnace will not operate unless

the polarity and ground are properly connected as

shown in

Thermostat / Low Voltage Connections

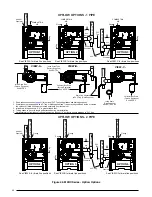

• The furnace is designed to be controlled by a 24 VAC

thermostat. The thermostat’s wiring must comply with

the current provisions of the NEC (ANSI/NFPA 70) and

with applicable local codes having jurisdiction.

• The thermostat must be installed according to the

instructions supplied by the thermostat manufacturer.

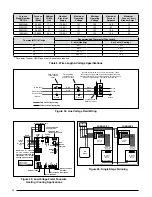

Low voltage connections (24 VAC) from the thermostat

are wired to the terminal strip on the integrated control

in the furnace.

proper connections for heating only (two-wire) and

heating/cooling (four-wire) applications. Recommended

minimum wire gauge for thermostat wiring is shown in

• The thermostat should be mounted about 5 feet above

the floor on an inside wall. DO NOT install the thermostat

on an outside wall or any other location where its

operation may be adversely affected by radiant heat from

fireplaces, sunlight, or lighting fixtures, and convective

heat from warm air registers or electrical appliances.

Refer to the thermostat manufacturer’s instruction sheet

for detailed mounting information.

• The six pin terminal marked “Expansion Port” (

) is not used in the single stage furnace as

shipped from the factory. It is used for the furnace control

board to communicate to a fixed speed or variable speed

high efficiency motor that may be optionally installed.

Please contact your distributor for the proper upgrade

motor kit. Please

Set the heat anticipator according

to the instructions supplied by the thermostat

manufacturer.

To determine the heat anticipator setting:

1. Add the current draw of the system components; or

2. Measure the current flow on the thermostat

R-W

circuit

after the circulating blower motor has started.

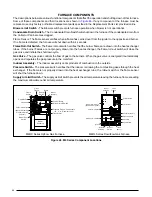

The six pin terminal marked “Expansion Port” is not used

in the single stage furnace as shipped from the factory. It

is used for the furnace control board to communicate to a

fixed speed or variable speed high efficiency motor that

may be optionally installed. Please contact your distributor

for the proper upgrade motor kit.

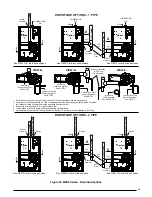

Twinning

WARNING:

When servicing either twinned furnace, power

must be turned off on both furnaces. Failure to

comply may result in improper operation leading

to damage to the furnaces or personal injury!

Single stage M4 furnaces are not supplied with a built-

in twinning capability. Other valuable features and

enhancements were made to the new control that made it

necessary to remove the twinning capability. For twinning

of single stage furnaces with PSC motors, a twinning kit

(920919) is available for purchase.

Please follow the

instructions provided with the kit.

If both single stage furnaces are upgraded to the fixed

speed iSEER ™ blower, the twin terminal on the blower

control boards

may be used to

twin the single stage furnaces only if the following criteria

are met:

• Both furnaces and motors must be the same size.

• Both motors must be on the same speed for cooling

and heating.

• Both furnaces must have a common return duct and

common supply plenum.

• Both furnaces must be the same phase and on the

same leg of power.

• Furnaces equipped with variable speed iSEER

™ motors may not be twinned under any

circumstances.

For twinning of single stage furnaces equipped with fixed

speed iSEER ™ blowers, refer to

following instructions:

1. Turn off all power to both furnaces.

2. Attach a wire between the two twin terminals on the

twinning control boards. Use field supplied wire and

two 3/16” wire terminals. NOTE: One furnace can be

used for one stage of heating and the other furnace can

be used for the second stage of heating. The installer

also has the choice of running one furnace only or both

furnaces. In both cases the blowers will run at the same

time and at the same speeds:

•

Single stage heating: The W connection on each

furnace must be connected together and then connected

to the W connection of the thermostat. This will allow

both furnaces to ignite at the same time for one stage

heating.

•

Two stage heating: The W connection on one

furnace must be connected to the W1 connection

of the thermostat. The W connection of the second

furnace must be connected to the W2 connection of

the thermostat. This will allow one furnace to ignite for

Summary of Contents for M4RC-072D-35C

Page 47: ...47...