35

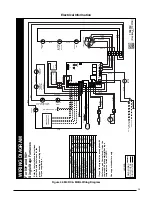

ELECTRICAL SHOCK, FIRE OR EXPLOSION

HAZARD

Failure to follow safety warnings exactly could

result in serious injury or property damage.

Improper servicing could result in dangerous

operation, serious injury, death or property

damage.

• Before servicing, disconnect all electrical

power to furnace.

• When servicing controls, label all wires prior

to disconnecting. Reconnect wires correctly.

• Verify proper operation after servicing.”

WARNING:

RISQUE DE CHOC ÉLECTRIQUE, D’INCENDIE

OU D’EXPLOSION

Le non-respect des avertissements de sécurité

pourrait entraîner

un fonctionnement dangereux

de l’appareil, des blessures graves, la mort ou

des dommages matériels.

Un entretein incorrect pourrait entraîner un

fonctionnement dangereux de l’appareil, des

blessures graves, la mort ou des dommages

matériels

• Couper toute alimentation électrique au

générateur d’air chaud avant de prodéder

aux travaux d’entretein.

• Au moment de l’entretien des commandes,

étiquetez tous les fils avant de les débrancher.

S’assurer de les raccorder correctement.

• S’assurer que l’appareil fonctionne

adéquatement aprés l’entretien.

AVERTISSEMENT

:

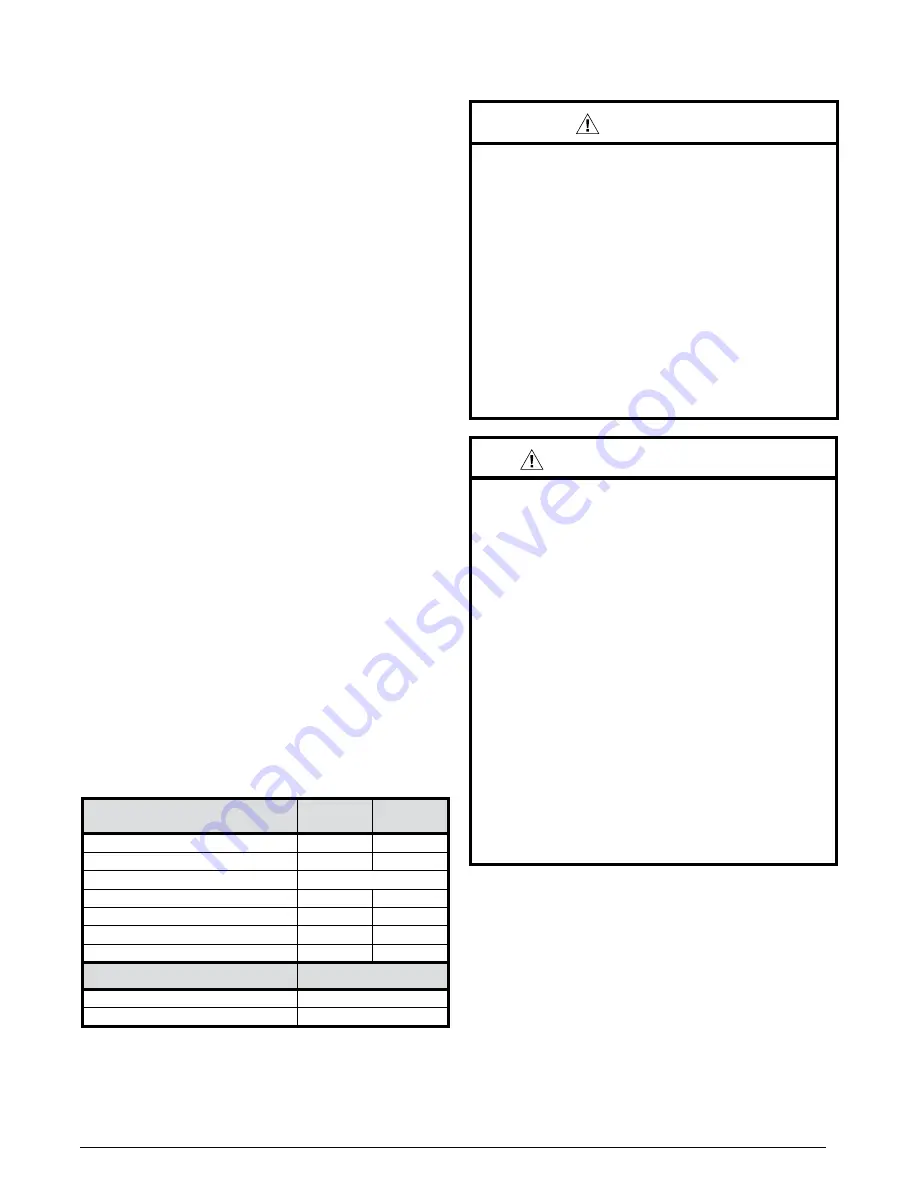

Table 6

DIAGNOSTIC DESCRIPTION

GREEN

LED

RED

LED

Control Fault (No Power)

Off

Off

L1/Neutral Polarity Fault

Flash

Flash

1 Hour Lockout

Alternating Flash

Normal Operation

On

On

Pressure Switch Closed Fault

On

Flash

Pressure Switch Open Fault

Flash

On

Open Limit Switch Fault

Flash

Off

DIAGNOSTIC DESCRIPTION

YELLOW LED

Low Flame Sensor Signal

Continuous Flash

Flame Present

On

Table 6.

Control Board Fault Codes

TROUBLESHOOTING

If the furnace fails to operate check the following:

• Is the thermostat operating properly?

• Are the blower compartment door(s) in place?

• Is the furnace disconnect closed?

• Has the circuit breaker tripped or the control board fuse

burned open?

• Is the gas turned on?

• Are any manual reset switches open?

• Is the filter dirty or plugged?

• Is the flame sensor coated? Remove and clean with

steel wool.

(Do not use emery cloth or sandpaper!)

• Is there blockage in the condensate drain switch? Also

verify that there is no double trapping of condensate.

• Is the secondary heat exchanger free of debris and

clogs?

• Is evaporator coil clean and free of debris

(If applicable).

• Are all the LED’s on the furnace control board constantly

ON? If not, refer to

) to determine fault

condition.

IMPORTANT NOTE:

The furnace will lock out after 5 failed attempts for

ignition and will try again every hour if the call for

heat remains.

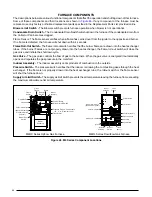

• If the Inducer Blower is operating, and items above have

been verified, check the blower limit switch and reset if

necessary. See

location.

• If the furnace operates when the blower limit switch is

reset, contact a qualified service technician to identify

and repair the problem.

• If the furnace still doesn’t operate, check the flame roll-

• If the furnace operates when the flame rollout switch is

reset, contact a qualified service technician to identify

and repair the problem.

•

Proper maintenance is most important to achieve the best

performance from a furnace. Follow these instructions

for years of safe, trouble free operation.

• These maintenance instructions are primarily intended

to assist qualified technicians experienced in the proper

maintenance and operation of this appliance.

• Always reinstall the doors on the furnace after servicing

or cleaning/changing the filters.

Do not operate the

furnace without all doors and covers in place.

• Verify the thermostat is properly installed and will not be

affected by drafts or heat from lamps or other appliances.

• To achieve the best performance and minimize

equipment failure it is recommended that a yearly

MAINTENANCE

Summary of Contents for M4RC-072D-35C

Page 47: ...47...