3

iMPortant SaFetY inForMation

Please read all information in this manual thoroughly

and become familiar with the capabilities and use of this

appliance before attempting to service or maintain this unit.

Safety markings are used frequently throughout this

manual to designate a degree or level of seriousness and

should not be ignored. WarninG indicates a potentially

hazardous situation that if not avoided, could result in

personal injury or death. caution indicates a potentially

hazardous situation that if not avoided, may result in minor

or moderate injury or property damage.

WarninG:

electrical SHocK, Fire or eXPloSion

HaZard

Failure to follow safety warnings exactly could

result in serious injury or property damage.

improper servicing could result in dangerous

operation, serious injury, death or property

damage.

• Before servicing, disconnect all electrical power

to the air handler.

• When servicing controls, label all wires prior

to disconnecting. reconnect wires correctly.

• Verify proper operation after servicing.

WarninG:

the information listed below must be followed

during the installation, service, and operation

of this unit. unqualified individuals should

not attempt to interpret these instructions or

install this equipment. if you do not posses

mechanical skills or tools, call your local

dealer for assistance. Failure to follow safety

recommendations could result in possible

damage to the equipment, serious personal

injury or death.

WarninG:

ProPoSition 65 WarninG: this product

contains chemicals known to the state of

california to cause cancer, birth defects or

other reproductive harm.

• To minimize equipment failure or personal injury, it is

essential that only qualified individuals install, service, or

maintain this equipment. If you do not posses mechanical

skills or tools, call your local dealer for assistance.

• Follow all precautions in the literature, on tags, and

on labels provided with the equipment. Read and

thoroughly understand the instructions provided with

the equipment prior to performing the installation and

operational checkout of the equipment.

• Use caution when handling this appliance or removing

components. Personal injury can occur from sharp metal

edges present in all sheet metal constructed equipment.

• Do not store any of the following on, or in contact with,

the unit: Rags, brooms, vacuum cleaners, or other

cleaning tools, spray or aerosol cans, soap powders,

bleaches, waxes, cleaning compounds, plastics or

plastic containers, paper bags or other paper products,

gasoline, kerosene, cigarette lighter fluid, dry cleaning

fluids, paint thinners, or other volatile fluids.

• Installation of equipment may require brazing operations.

Installer must comply with safety codes and wear

appropriate safety equipment (safety glasses, work

gloves, fire extinguisher, etc.) when performing brazing

operations.

• Unless otherwise noted in these instructions, only factory

authorized kits or accessories may be used with this

product.

• The installer should become familiar with the units wiring

diagram before making any electrical connections to the

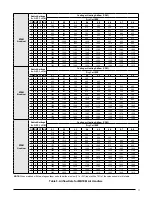

unit. See the unit wiring label or Figures 14 - 16 (pages

24 - 26).

• Always reinstall the doors on the air handler after

servicing or cleaning/changing the filters. Do not operate

the air handler without all doors and covers in place.

General inForMation

requirements & codes

• The installer must comply with all local codes and

regulations which govern the installation of this type

of equipment. Local codes and regulations take

precedence over any recommendations contained in

these instructions. Consult local building codes for

special installation requirements.

• All electrical wiring must be completed in accordance

with local, state and national codes and regulations

and with the National Electric Code (ANSI/NFPA 70)

or in Canada the Canadian Electric Code Part 1 CSA

C.22.1.

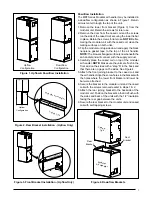

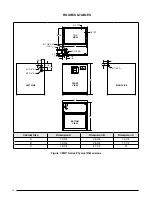

• Install this unit only in a location and position as

specified on page 4. This unit is designed only for Indoor

installations and should be located with consideration

of minimizing the length of the supply and return ducts.

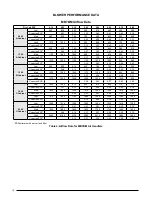

See Tables 4 - 8 (pages 16 - 19) and the rating plate for

proper circulating airflow data.

• This air handler may be used for temporary heating

of buildings or structures under construction. See the

guidelines listed on page 4.

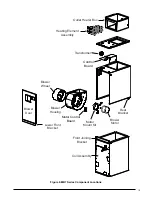

about the air Handler

This appliance has been tested for capacity and efficiency

in accordance with AHRI Standards and will provide

many years of safe and dependable comfort, providing

it is properly installed and maintained. Abuse, improper

use, and/or improper maintenance can shorten the life of

the appliance and create unsafe hazards. Please read all

instructions before installing the unit.