6

around penetrations into the air handler, such as for

electrical wiring.

Air Filters

WarninG:

never operate the air handler without a filter

or with doors removed. dust and lint can build

up on internal components, resulting in loss of

efficiency, equipment damage, and possible fire.

MB7 Series air handlers are not equipped with filter

racking; however, NORDYNE strongly recommends that

a filter be located in the return air duct system. Installing

the filter and replacing it every 3 months will increase air

quality throughout the home.

Unconditioned Spaces

All duct work passing through unconditioned space must

be properly insulated to minimize duct losses and prevent

condensation. Use insulation with an outer vapor barrier.

Consult your Distributor for the recommended type and

thickness of insulation for your area as required by local

codes.

condensate drainage

caution:

the air handler must be level to ensure proper

condensate drainage. an unlevel installation

may result in structural damage, premature

equipment failure, or possible personal injury.

• Modular air handlers are intended to be mated with

specific NORDYNE C6 cased coils. To ensure proper

condensate drainage, the unit must be installed in a

level position within 1/4 inch over the height, width, and

depth of the unit. The best system performance will be

obtained if the unit is located in a centralized position

with respect to the air distribution system. Refer to the

Installation Instructions supplied with the Cased Coil

for proper condensate drain connections.

• If the air handler is located in or above a living space

where damage may result from condensate overflow,

an auxiliary drain pan should be installed under the unit.

A separate drain line should extend from the pan to a

conspicuous point and serve as an alarm indicating

that the primary drain is restricted. As an alternative to

a separate drain line, an approved water level indicator

or float switch device should be used to shut down the

unit in the event water is detected in the auxiliary pan.

• During system checkout, inspect the drain line and

connections to verify proper condensate drainage.

• Methods for disposing of condensate vary according

to local codes. Refer to local codes or authority having

jurisidiction for restrictions and proper condensate

disposal requirements.

air Handler inStallation

The MB7 Series air handler is shipped ready for vertical

upflow installation and is approved for attic, basement,

alcove/closet or crawlspace installation with zero clearance

to combustibles. They may also be applied in downflow

or horizontal left and right discharge applications. See

Table 1 (page 4) for required installation clearances. this

appliance is approved only for indoor use.

note: For shipping purposes, the front and rear joining

brackets are located in the unit’s heater box. Remove

these two items from the heater box before beginning.

• The unit must be leveled at installation and attached to

a properly installed duct system.

• The surface that the air handler is mounted on must

provide sound physical support of the unit.

• The air handler must be installed so that all electrical

components are protected from water.

• If a louvered door is installed across the front of this

unit, the appliance must be mounted flush or behind

front edge of finished wall.

•

Modular air handlers are intended to be mated with

specific NORDYNE C6 cased coils. Reference the

Technical Specifications for coil mating combinations.

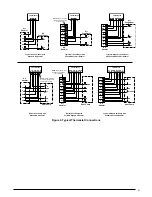

upflow installation

The MB7 Series air handler is shipped from the factory

ready for upflow configuration as shown in Figure 1 (page

7). Return air must must enter from the bottom of the unit.

1. Remove the bracket above the door of the cased coil.

Retain the screws for later use. note: Before mating

the modular unit with the cased coil, clean the mating

surfaces on both units and apply the black neoprene

gasket tape to the top of the coil case (except the rear

surface). Make sure there are no gaps on the front and

side flanges.

2. Carefully place the modular air handler on top of the

cased coil making sure not to damage the cased coil

flanges. The units will be flush in front with an overhang

in the back as shown in Figure 2 (page 7).

3. Remove the lower front bracket (Figure 3, page 7) from

the modular unit. Retain the screws for later use.

4. Attach the front joining bracket to the front of the modular

unit. Align the screw holes in the bracket with the holes

from the lower front bracket and the top panel of the

coil case. See Figure 3.

5. Secure the bracket with the screws removed earlier in

steps 1 & 2.

6. Attach the rear joining bracket to the backside of the

modular unit and cased coil. Position the bracket so that

it is flush with the sides and back of the units with the

1/2” insulation facing the rear gap between the units.

7. Secure the rear bracket with self tapping screws.