11

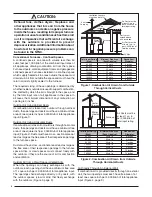

VENTING REQUIREMENTS

WARNING:

This furnace must not be vented with other

appliances, even if that appliance is of the

condensing type. Common venting can result

in severe corrosion of other appliances or their

venting and can allow combustion gases to

escape through such appliances or vents. Do

not vent the furnace to a fi replace chimney or

building chase.

This furnaces is classifi ed as a “Category IV” appliance,

which requires special venting materials and installation

procedures.

• This furnace must be vented in compliance with

the current revision of the National Fuel Gas Code

(ANSI-Z223.1/NFPA54) and the instr uctions

provided below.

Consult local codes for special

requirements.

• In Canada, venting shall conform to the requirements of

the current (CAN/CGA B149.1 or .2) installation codes.

Consult local codes for special requirements.

• Additional reference information for US and Canadian

installations can be found in the Combustion and

Ventilation Air section (page 5).

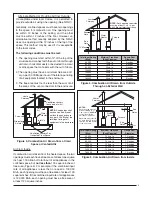

This section specifies installation requirements for

Conventional (1-pipe) and Direct Vent (2-pipe) piping. For

1- pipe installations, install vent piping per this section and

provide air for combustion and ventilation per the previous

section. Table 15 (page 44) contains the length of vent and

combustion air piping for either type of installation.

Category IV appliances operate with positive vent pressure

and therefore require vent systems which are thoroughly

sealed. They also produce liquid condensate, which is

slightly acidic and can cause severe corrosion of ordinary

venting materials. Furnace operation can be adversely

affected by restrictive vent and combustion air piping.

The inducer assembly on this furnace can be rotated to

vent the fl ue products out of the top, left or right side. This

increases the fl exibility of which direction the vent pipe

can exit the furnace.

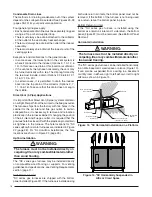

WARNING:

Upon completion of the furnace installation,

carefully inspect the entire fl ue system both

inside and outside the furnace to assure it is

properly sealed. Leaks in the fl ue system can

result in serious personal injury or death due

to exposure of fl ue products, including carbon

monoxide.

Vent Pipe Material

Vent and combustion air pipe and fi ttings must be one of

the following materials and must conform to the indicated

ANSI/ASTM standards. In Canada, all plastic vent pipes

and fi ttings including any cement, cleaners, or primers

must be certifi ed as a system to ULC S636.

Material

.......................................

Standard

Schedule

40PVC

............................D1785

PVC-DWV

....................................... D2665

SDR-21 & SDR-26 ..........................D2241

ABS-DWV

....................................... D2661

Schedule 40 ABS ............................ F628

Foam/Cellular Core PVC ................ F891

Cement and primer must conform to ATSM Standard

D2564 for PVC and Standard D2235 for ABS. When

joining PVC piping to ABS, use PVC solvent cement. (See

procedure specifi ed in ASTM Standard D3138).

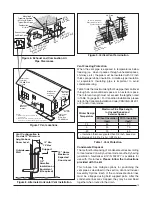

Vent Pipe Length and Diameter

In order for the furnace to operate properly, the combustion

air and vent piping must not be excessively restrictive.

• The venting system should be designed to have the

minimum number of elbows or turns.

• All horizontal runs must slope upwards from the furnace

at 1/4 inch minimum per running foot of vent.

• Transition to the fi nal vent diameter should be done as

close to the furnace outlet as practical.

• Always use the same size or a larger pipe for combustion

air that is used for the exhaust vent.

Table 15 indicates the maximum allowable pipe length for

a furnace of known input rate, when installed with piping

of selected diameter and number of elbows. To use the

table, the furnace input rate, the centerline length and the

number of elbows on each pipe must be known.

When estimating the length of vent runs, consideration

must be made to the effect of elbows and other fi ttings.

This is conveniently handled using the idea of “equivalent

length”. This means the fi ttings are assigned a linear

length that accounts for the pressure drop they will cause.

For example: a 2” diameter, long radius elbow is worth

the equivalent of 2.5 feet of linear run. A 90 degree tee

is worth 7 ft.

Using Table 15, measure the linear length of your vent run

and then add in the equivalent length of each fi tting. The

total length, including the equivalent fi tting lengths, must

be less than the maximum length in Table 15.

Condensing furnace combustion products have very little

buoyancy, so Table 15 is to be used without consideration

of any vertical rise in the piping.