14

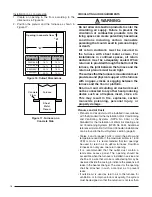

Before using Table 2, the number of pipes (1-pipe or 2-pipe)

connected to the furnace must be known. Find the proper

furnace style (upfl ow, horizontal, or downfl ow) and then

the side that the pipes will exit from the furnace. Finally

select the option that properly matches your installation

type from Figures 25-28 (pages 39-42).

Existing Installations

When an existing furnace is removed from a vent system

serving other appliances, the existing vent system may

not be sized properly to vent the remaining appliances

(For example: water heater). An improperly sized venting

system can result in the formation of condensate, leakage,

or spillage. The existing vent system should be checked

to make sure it is in compliance with NFGC and must be

brought into compliance before installing the furnace.

NOTE:

If replacing an existing furnace, it is possible you

will encounter an existing plastic venting system that is

subject to a Consumer Product Safety Commission recall.

The pipes involved in the recall are High Temperature

Plastic Vent (HTPV).

If your venting system contains

these pipes

DO NOT reuse this venting system!

This

recall does not apply to other plastic vent pipes, such

as white PVC or CPVC. Check for details on the CPSC

website or call their toll-free number (800) 758-3688.

FURNACE INSTALLATION

General Requirements

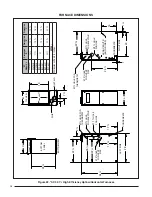

*SC series gas furnaces are shipped ready for installation

in the upfl ow or horizontal right or left positions. Only

the *SL series gas furnace may be used for downfl ow

operation.

• The furnace must be leveled at installation and attached

to a properly installed duct system. See Table 3 (page

27) for the required clearances needed to move the

furnace to its installation point (hallways, doorways,

stairs, etc).

• The furnace must be installed so that all electrical

components are protected from water.

• The furnace must be installed upstream from a

refrigeration system.

• The cabinet plug must always be used to close the hole

in the side of the furnace when rotating the inducer.

• Additional reference information for US and Canadian

installations can be found in the General Installation

section (page 5).

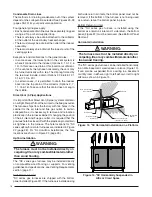

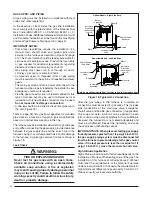

Vent and Inducer Assembly Options

*SC series gas furnaces offer a wide range of installation

options, including installation in the upfl ow or horizontal

positions with either right, left, or upfl ow return air. The

*SL series gas furnaces may only be installed as a down

fl ow application.

To increase installation fl exibility, the inducer assembly can

be rotated up to 3 different positions. Each variation has

slightly different requirements with regard to condensate

disposal and, in some cases, the need to seal the furnace

cabinet.

IMPORTANT NOTE: The Inducer Assembly

must never be positioned to vent downwards on

horizontal installs.

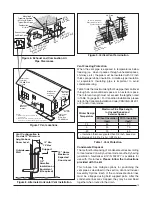

Inducer Assembly Rotation

WARNING:

Inducer rotation must be completed before

the furnace is connected to gas and electric. If

both utilities have been connected, follow the

shutdown procedures printed on the furnace

label and disconnect the electrical supply.

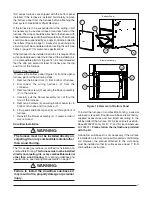

1. Disconnect the electrical harness (1) from the inducer

assembly (2) as shown in Figure 10 (page 15).

2. Remove the inducer assembly ground wire (3) from

the blower deck (4) or door.

3. Remove three screws (5) securing the inducer

assembly (2) to the header box (6).

4. Rotate the inducer assembly (2) to its new position.

5. Secure the inducer assembly (2) to the header box

(6) by reinstalling the three screws (5). If the inducer

assembly is rotated to the left or right side of the

furnace, use the extra screw provided in the parts

package.

6. Remove the cabinet plug (7) from side of furnace and

reinstall in hole on opposite side of cabinet.

7. Install in-line drain assembly and tubing.

8. If applicable, install the condensate drain lines as

shown in (Figures 25-28).

9. Reconnect the electrical harness (1) to the inducer

assembly (2).

10. Reconnect the inducer assembly ground wire (3) to

the blower deck (4) or door.

11. Verify operation as detailed on the furnace label.

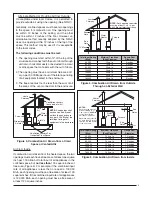

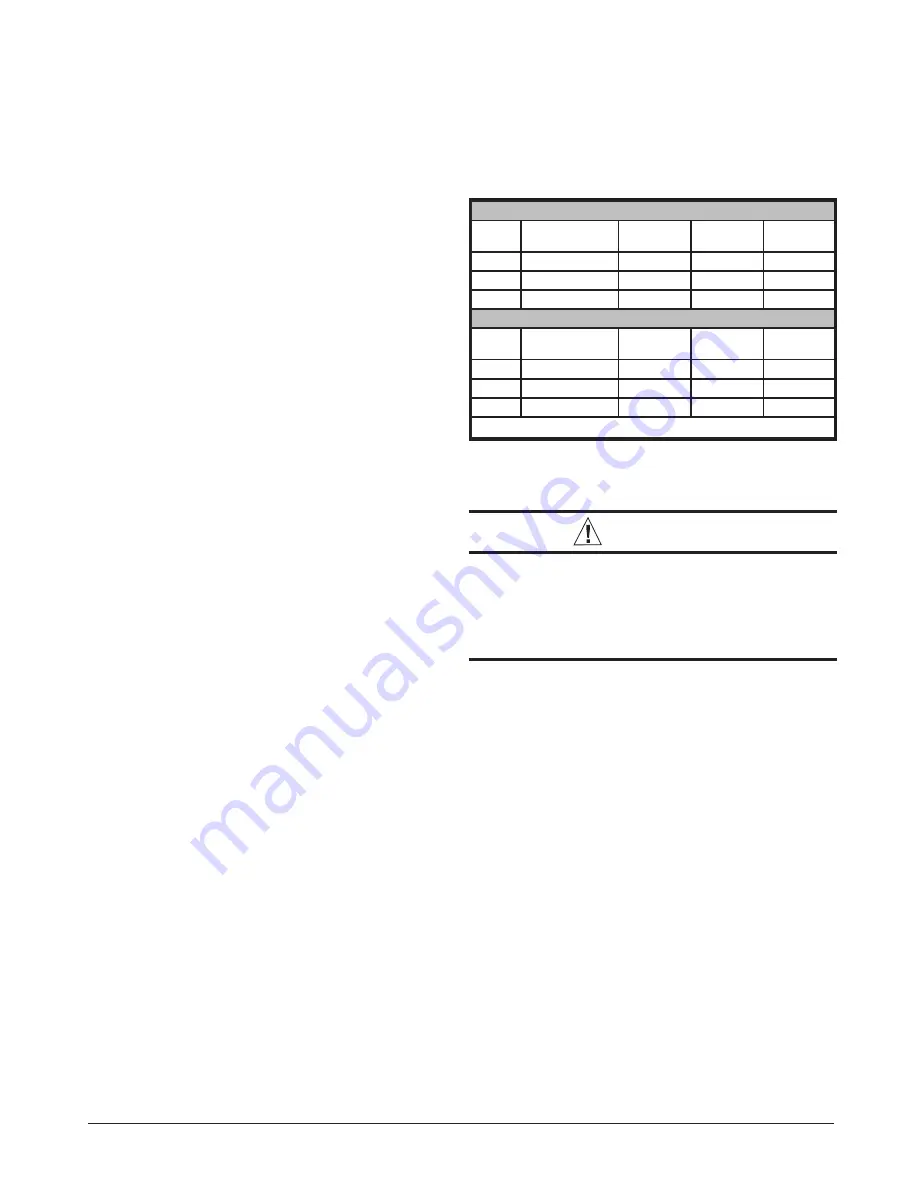

Table 2. Vent and Inducer Blower Options

Conventional (1 Pipe)

Vent

Upfl ow

Horizontal

Right

Horizontal

Left

Downfl ow

Up

Option 1

Option 7

Option 10

Option 15

Right

Option 2

Option 8

N/A

Option 16

Left

Option 3

N/A

Option 9

Option 17

Direct Vent (2-pipe)

Vent

Upfl ow

Horizontal

Right

Horizontal

Left

Downfl ow

Up

Option 4

Option 12*

Option 14*

Option 18

Right

Option 5*

Option 11

N/A

Option 19*

Left

Option 6*

N/A

Option 13

Option 20*

* Requires a 2 inch PVC endcap.