25

OPERATING SEQUENCE

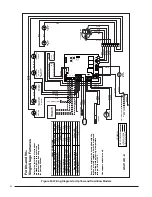

The operating sequences for the heating, cooling, and fan

modes are described below. Refer to the fi eld and furnace

wiring diagrams: (Figure 19 page 22), (Figure 20, page

22) and (Figure 24, page 34).

Heating Cycle

1. The thermostat calls for heat by energizing the

W

terminal with 24VAC.

2. The control verifi es the pressure switch is open.

3. If the pressure switch is open, the control energizes

the inducer and waits for the pressure switch to close.

The pressure switch must close within 10 seconds.

4. The control runs the inducer for a 30 second pre-

purge.

5. The control energizes the Hot Surface Igniter (HSI)

output for the appropriate warm-up time limit.

6. The control energizes the main gas valve for 3

seconds.

7. If the fl ame proved and ignites the gas, the control de-

energizes the HSI. The gas valve and inducer remains

energized. The control goes to blower on delay.

8. If fl ame is present, the control energizes the blower

on the selected HEAT speed 30 seconds after the

gas valve opened. The gas valve and inducer remain

energized.

9. When the thermostat demand for heat is satisfi ed, the

control de-energizes the gas valve. The Inducer output

remains on for a 30 second post-purge period.

10. Blower off timing begins when the thermostat is

satisfi ed. The control will operate at the selected HEAT

speed of 60, 90, 120, or 180 seconds. If the blower

off delay jumper is not present, the fan should still

operate for 120 seconds at the selected HEAT speed.

The Indoor blower motor is de-energized after a blower

off delay as selected by the movable jumper.

Cooling Cycle

1. The thermostat calls for cooling by energizing the

Y

terminal with 24VAC.

2. The control energizes the blower in cooling speed

and sends 24VAC to the contactor in the condensing

unit

3. When the thermostat removes the call for cooling,

the contactor in the outdoor condensing unit is de-

energized and the control continues to run the fan for

a period of 60 seconds.

Fan Mode

• When the thermostat energizes the

G

terminal for

continuous fan (without calling for heat or cooling), the

indoor fan is energized on the selected FAN speed.

• If a call for cooling occurs during continuous fan, the

blower will switch over to the selected COOL speed.

• If

the

W

terminal receives a call for heat during

continuous fan, the blower will de energize.

•

A call for fan is ignored while in lockout.

MAINTENANCE

WARNING:

These maintenance instructions are primarily

intended to assist qualified technicians

experienced in the proper maintenance and

operation of this appliance.

Proper maintenance is most important to achieve the best

performance from a furnace. Follow these instructions for

years of safe, trouble free operation.

•

Always replace the doors on the furnace after servicing

or cleaning/changing the fi lters.

Do not operate the

furnace without all doors and covers in place.

• Verify the thermostat is properly installed and will not be

affected by drafts or heat from lamps or other appliances.

• To achieve the best performance and minimize

equipment failure it is recommended that a yearly

maintenance checkup be performed. At a minimum,

this check should include the following items:

Air Filter(s)

WARNING:

Never operate the furnace without a fi lter in

place. Dust and lint can build up on internal

components, resulting in loss of effi ciency,

equipment damage, and possible fi re.

NOTE:

Air fi lter(s) are not supplied with the furnace as

shipped from the factory. The installer must provide a

high velocity fi lter and rack for a fi lter in the return air

duct adjacent to the furnace, or in a return air grill to the

furnace. It is recommended that fi lters be cleaned or

replaced monthly. New or newly renovated homes may

require more frequent changing until the construction

dust has minimized.

Filters designed to remove smaller particles such as

pollen, may require additional maintenance. Filters for

side return and bottom return applications are available

from most local distributors.

Blower Compartment

Dirt and lint can create excessive loads on the motor

resulting in higher than normal operating temperatures

and shortened service life. It is recommended that the

blower compartment be cleaned of dirt or lint that may

have accumulated in the compartment or on the blower

and motor as part of the annual inspection.