7

Installation in a Garage

WARNING:

Do not place combustible material on or

against the furnace cabinet or within 6 inches

of the vent pipe. Do not place combustible

materials, including gasoline or any other

fl ammable vapors and liquids, in the vicinity

of the furnace.

This Gas-fi red furnace may be installed in a residential

garage with the provision that the burners and igniter

are located no less than 18 inches (457mm) above the

fl oor. The furnace must be located or protected to prevent

physical damage by vehicles.

Heating Load

This furnace should be sized to provide the design heating

load requirement. Heating load estimates can be made

using approved methods available from Air Conditioning

Contractors of America (Manual J); American Society of

Heating, Refrigerating, and Air Conditioning Engineers;

or other approved engineering methods.

Excessive

oversizing of the furnace could cause the furnace

and/or vent to fail prematurely.

In addition, the ductwork

should be appropriately sized to the capacity of the

furnace to ensure its proper airfl ow rating. For installations

above 2,000 ft., the furnace should have a sea level input

rating large enough that it will meet the heating load after

deration for altitude.

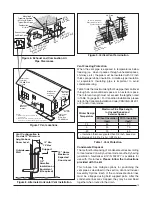

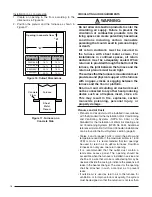

Clearances to Combustible Materials

This furnace is Design Certifi ed in the U.S. and Canada

by CSA International for the minimum clearances to

combustible material listed in Table 3 (page 27). To obtain

model number and specifi c clearance information, refer

to the furnace rating plate, located inside of the furnace

cabinet.

Access for positioning and servicing the unit must be

considered when locating unit. The minimum required

clearance from the front of the unit for servicing is 24

inches. The minimum required clearance for positioning

is 30 inches from the front of the unit.

The recommended

clearance from the front of the unit is 36 inches.

The

need to provide clearance for access to panels or doors

may require clearance distances over and above the

requirements.

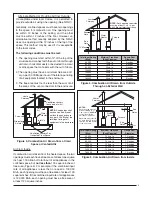

COMBUSTION AIR REQUIREMENTS

General Information

WARNING:

Furnace installation using methods other than

those described in the following sections must

comply with the National Fuel Gas Code (NFGC)

and all applicable local codes.

• Instructions for determining the adequacy of an

installation can be found in the current revision of the

NFGC (ANSI Z223.1 / NFPA54).

Consult local codes

for special requirements

. These requirements are for

US installations as found in the NFGC.

• The requirements in Canada (B149.1) are structured

differently. Consult with B149.1 and local code offi cials

for Canadian installations.

• Additional reference information for US and Canadian

installations can be found in the Combustion and Ven-

tilation Air section (page 5).

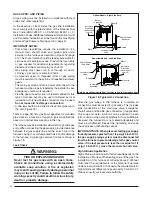

This condensing furnace is certifi ed for installation either as

a Direct Vent (2-pipe) or Conventional (1-pipe) appliance.

Direct Vent appliances draw combustion air from the

outdoors and vent combustion products back outside.

Installation with air taken from around the furnace is often

referred to as Conventional installation - i.e. only the vent

(exhaust) pipe is provided.

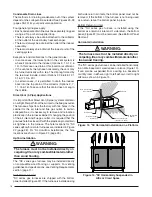

Provisions must be made during the installation of

this furnace that provide an adequate supply of air for

combustion. The combustion air from the outside needs

to be clear of chemicals that can cause corrosion. The

inlet pipe should not be placed near corrosive chemicals

such as those listed on page 6.

Another important consideration when selecting one or

two pipe installation is the quality of the Indoor air which

can sometimes be contaminated with various household

chemicals . These chemicals can cause severe corrosion

in the furnace combustion system.

A 2-pipe installation

has the additional advantage that it isolates the system

from the effects of negative pressure in the house.

NOTE

: Air openings on top of the furnace and openings

in closet doors or walls must never be restricted. If the

furnace is operated without adequate air for combustion,

the fl ame roll-out switch will open, turning off the gas

supply to the burners. This safety device is a manually

reset switch.

DO NOT install jumper wires across these

switches to defeat their function or reset a switch

without identifying and correcting the fault condition.

If

a switch must be replaced, use only the correct sized part

specifi ed in the Replacement Parts List provided online.