16

Downfl ow Installation

WARNING:

The furnace must not be installed directly on

carpeting, tile, or any combustible material other

than wood fl ooring.

WARNING:

Failure to install the downfl ow sub-base kit

may result in fi re, property damage or personal

injury.

To install the furnace on combustible fl ooring, a special

sub-base is required. Downfl ow sub-base kits are factory

supplied accessories and are listed according to the cabinet

letter of the furnace. For ‘B’, ‘C’, and ‘D’ size cabinets use

Kit #904911.

Please follow the instructions provided

with the kit.

A downfl ow sub-base kit is not necessary if the furnace

is installed on a factory or site-built cased air conditioning

coil. However, the plenum attached to the coil casing

must be installed so that its surfaces are at least 1” from

combustible construction.

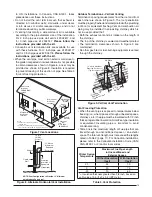

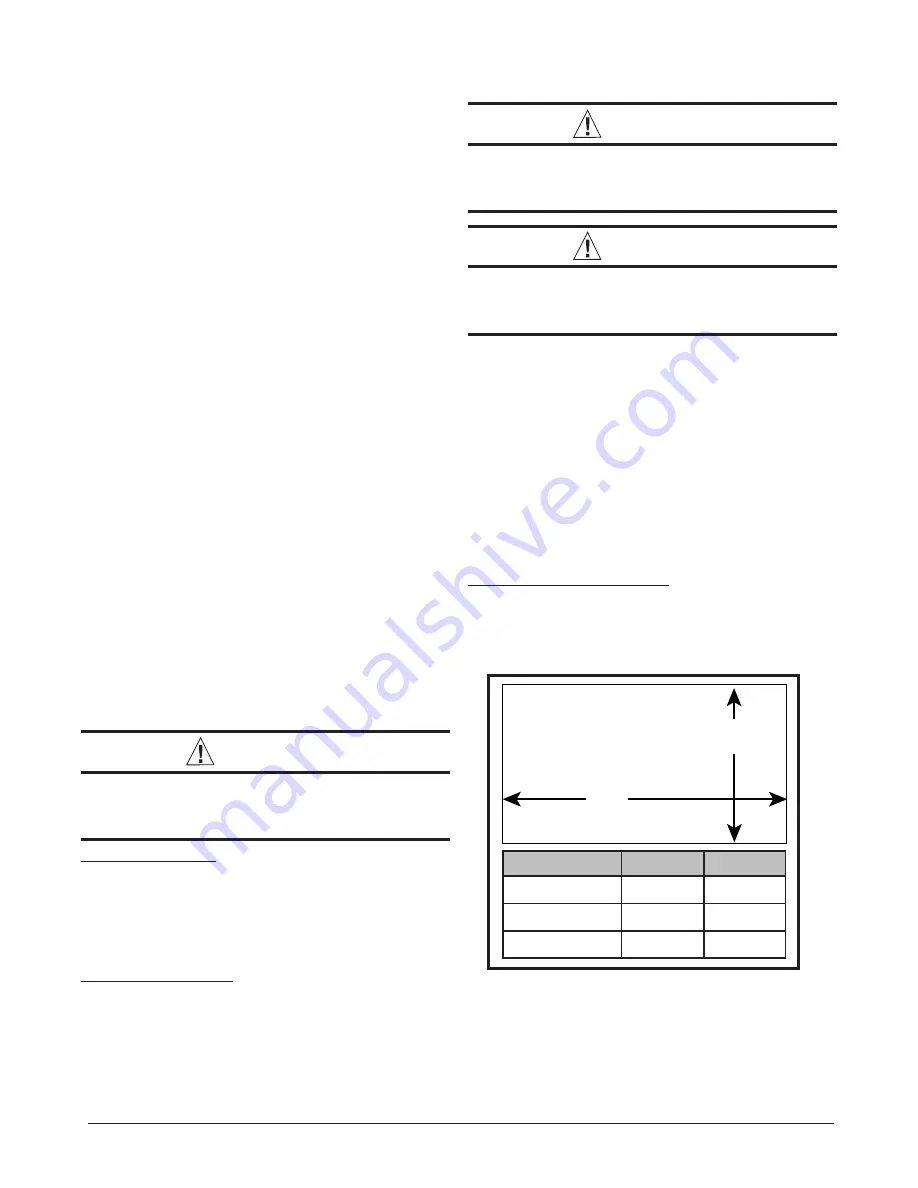

Installation on a concrete slab.

1. Create an opening in the fl oor according to the

dimensions in Figure 10.

2. Position the plenum and the furnace as shown in

Figure 11 (page 17).

Cabinet Size Dim. “A” Dim. “B”

‘B’

16

⅝

19

¼

‘C’

20

⅛

19

¼

‘D’

23

⅝

19

¼

“A”

“B”

Opening in concrete floor

Figure 10. Cutout Dimensions

FURNACE INSTALLATION

*TC series gas furnaces offer a wide range of installation

options, including installation in the upfl ow or horizontal

positions with either right, left, or upfl ow return air. The

*TL series gas furnaces may only be installed as a down

fl ow application.

General Requirements

• The furnace must be leveled at installation and

attached to a properly installed duct system. See

Table 1 (page 7) for the required clearances needed

to move the furnace to its installation point (hallways,

doorways, stairs, etc).

• The furnace must be installed so that all electrical

components are protected from water.

• The furnace must be installed upstream from a

refrigeration system. (If applicable)

• The cabinet plug must always be used to close the hole

in the side of the furnace when rotating the inducer.

• The furnace requires special venting materials and

installation procedures. See pages 10 -14 for venting

guidelines and specifi cations.

Direct Vent (2-Pipe) Applications

It is important that Direct Vent (2-pipe) systems maintain

an airtight fl ow path from the air inlet to the fl ue gas outlet.

The furnace ships from the factory with two holes in the

cabinet for the air inlet and fl ue gas outlet. In certain

confi gurations, it is necessary to remove and relocate a

plastic cap in the furnace cabinet. If changing the position

of the air inlet and fl ue gas outlet, it is required that the

previous hole be closed off with the plastic cap to maintain

air tightness in the furnace. The hole locations for *TC and

*TL furnaces are shown in Figure 28 (page 34).

Upfl ow Installation

WARNING:

The furnace must not be installed directly on

carpeting, tile, or any combustible material other

than wood fl ooring.

Side Return Air Inlet

*TC series gas furnaces are shipped with the bottom panel

installed (Figure 28). If the upfl ow furnace is installed using

both side return air inlets, the bottom panel must not be

removed. The bottom panel must be in place if the bottom

of the furnace is not being used as a return.

Bottom Return Air Inlet

If the *TC series gas furnace is installed using the bottom

as a return air inlet and 1 side return, the bottom panel

(Figure 28) must be removed.