22

After the gas piping to the furnace is complete, all

connections must be tested for gas leaks. This includes

pipe connections at the main gas valve, emergency shutoff

valve and fl exible gas connectors (if applicable). The soap

and water solution can be applied on each joint or union

using a small paintbrush. If any bubbling is observed,

the connection is not sealed adequately and must be

retightened. Repeat the tightening and soap check process

until bubbling ceases.

IMPORTANT NOTE: When pressure testing gas supply

lines at pressures greater than 1/2 psig (14 inch W.C.),

the gas supply piping system must be disconnected

from the furnace to prevent damage to the gas control

valve. If the test pressure is less than or equal to 1/2

psig (14 inch W.C.), close the manual shut-off valve.

High Altitude Application

The installation of this furnace at altitudes above 2,000

feet must meet the requirements of the National Fuel Gas

Code or local jurisdiction. In Canada, the requirements for

high altitude are different and governed by CGA B149.1.

Please consult your local code authority.

WARNING:

The reduction of input rating necessary for high

altitude installation may only be accomplished

with factory supplied orifi ces. Do not attempt

to drill out orifi ces in the fi eld. Improperly

drilled orifi ces may cause fi re, explosion,

carbon monoxide poisoning, personal injury

or death.

The furnaces are shipped from the factory with orifi ces

and gas regulator settings for natural gas operation at sea

level altitudes. At 2000 feet, the NFGC requires that this

appliance be derated 4% for each 1000 feet of altitude.

For example, the input needs to be reduced 8% at 2,000

feet, 12% at 3,000 feet, etc. This deration is in reference

to the input rate and gas heating value at sea level.

To derate the furnace requires knowing the heating value of

the gas at the installation site. Heating values at particular

job sites vary for two reasons:

1. The chemical mixture of the gas varies from region

to region and is expressed as the “sea level heating

value”.

2. The heating value varies by altitude. For this reason,

particularly in high altitude areas, the local gas utility

usually specifi es the heating value at the residence’s

gas meter as the “local value”.

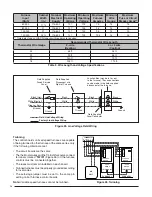

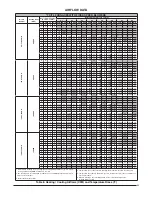

For added fl exibility, two tables have been provided for

natural gas installations with high or low heating values at

sea level. Tables 15 and 16 (page 40) contain the orifi ce

sizes and manifold pressure to use at various altitudes.

Table 15 (HIGH) is for natural gas installations with a

INSTALLATION EXAMPLE

Elevation:

................................................5,000 feet

Type of Gas:

.........................................Natural Gas

Local Heating Value of Gas:

............................750

From Table 14, fi nd 750 and follow down the column,

stop at the 5,000 feet row. The heating value listed is

LOW. Table 16 will be used to determine orifi ce size and

manifold pressure.

heating value of more than 1,000 Btu per cubic foot and

Table 16 (LOW) is for less than 1,000 Btu per cubic foot.

To determine which table to use:

1. Consult your local utility for the local heating value at

your installation.

2. From Table 14 (page 39), fi nd your local heating value

as supplied by the utility company. Follow down the

column and stop at your altitude level.

3. If your sea level heating value is HIGH, use Table 15

or if it’s LOW, use Table 16. See example.

After changing the regulator pressure or changing the

orifi ces, it is required that you measure the gas input

rate. This may be accomplished in the usual way, by

clocking the gas meter and using the local gas heating

value. See Verifying and Adjusting the Input Rate section

(page 27).

IMPORTANT NOTE: Observe the action of the burners

to make sure there is no yellowing, lifting or fl ashback

of the fl ame.

Conversion to LP/Propane

WARNING:

The furnace was shipped from the factory

equipped to operate on natural gas. Conversion

to LP/propane gas must be performed by

qualifi ed service personnel using a factory

supplied conversion kit. Failure to use the

proper conversion kit can cause fi re, explosion,

property damage, carbon monoxide poisoning,

personal injury, or death.

Conversion to LP/propane is detailed in the installation

instructions provided with the conversion kit. Generally,

this will require the replacement of the burner orifi ces and

the spring/stem assembly in the pressure regulator.

Approved conversion kits are listed below.

Please follow

the instructions provided with each kit

.

• The United States LP/Propane Gas Sea Level and High

Altitude Conversion Kit (P/N 904914) is for LP/propane

conversion in the United States at altitudes between

2,000 ft. and 10,000 ft. above sea level.