23

• The Canadian LP/Propane Gas Sea Level and High

Altitude Conversion Kit (P/N 904915) is for LP/propane

conversions in Canada at altitudes between zero and

4,500 ft. above sea level.

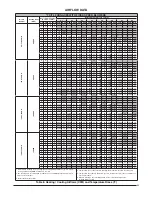

In the U.S., if installation is above 2,000 ft., refer to Table

13 (page 39) to determine the correct orifi ce size and

regulator pressure. When conversion is complete, verify

the manifold pressure and input rate are correct as listed

in the tables.

ELECTRICAL WIRING

WARNING:

ELECTRICAL SHOCK, FIRE OR EXPLOSION

HAZARD

Failure to follow safety warnings exactly could

result in dangerous operation, serious injury,

death or property damage.

Improper servicing could result in dangerous

operation, serious injury, death or property

damage.

•

Before servicing, disconnect all electrical

power to furnace.

•

When servicing controls, label all wires prior to

disconnecting. Reconnect wires correctly.

•

Verify proper operation after servicing.

• Electrical connections must be in compliance with all

applicable local codes, and the current revision of the

National Electric Code (ANSI/NFPA 70).

• For Canadian installations the electrical connections

and grounding shall comply with the current Canadian

Electrical Code (CSA C22.1 and/or local codes).

IMPORTANT NOTE: If replacing any of the original wires

supplied with the furnace, the replacement wire must

be copper wiring and have a temperature rating of at

least 105°F (40°C). For electrical specifi cations, refer

to the furnace nameplate or Table 5 (page 26).

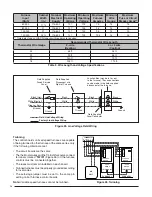

Two-stage furnaces use high effi ciency circulating air

motors that come in two variations and both are controlled

differently. The fi xed speed motor control board (Figure

29, page 41) controls the torque and the variable speed

motor control board (Figure 30) controls the airfl ow at a

constant CFM. Both boards use the same furnace control

board (Figure 29).

Fixed Speed Blower Applications

NOTE:

This section applies only to furnaces with model

numbers suffi xed with two numbers, followed by a letter,

such as 35C or 45D. If your model has suffi x VA, VB,

VC, or VD, please consult the Variable Speed Blower

Application section.

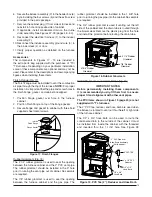

The fi xed speed motor control board (Figure 29) contains

a set of dip switches for setting the blower speed. Use

pins 1 to 4 to set the blower speed for heating and pins

5 to 8 to set the speed for cooling. To determine the

appropriate switch settings for your installation, refer to

Table 8 (page 35).

For thermostats with a dehumidifi er output, use a fi eld

supplied wire to connect the thermostat’s dehumidifi er

output to the terminal marked

“DHUM”

. The thermostat

should be set so that the

DHUM

output should be high

(positive) when dehumidifi cation is needed. See page 25

for additional dehumidifi cation options.

CAUTION:

The terminal marked “Y1_IN” on the variable

speed motor control board is not an output to

drive the outdoor unit. DO NOT connect Y1_IN on

the motor control board to the outdoor unit.

Variable Speed Blower Applications

NOTE:

This section applies only to models ending with

the suffi xes VA, VB, VC, or VD.

The variable speed motor control board (Figure 30, page

41) has a set of dip switches for setting the base blower

speed. Use pins 1 to 4 to set the blower speed for heating

and pins 5 to 8 to set the speed for cooling. To determine

the appropriate switch settings for your installation, see

Table 9 (page 36) for heating or Table 10 (page 37) for

cooling.

Use fi eld supplied wire to connect the thermostat’s

dehumidifi er output to the terminal marked

“DHUM”

. The

thermostat should be set so that the

DHUM

output is high

(positive) when dehumidifi cation is needed. See page 25

for additional dehumidifi cation options.

CAUTION:

The variable speed control board is also used

by other appliances. Many of the terminals and

connections on the board are for other appliances

and are not used in the two stage application. The

only two-stage fi eld connection to this board is

the DHUM terminal, used to reduce the blower

speed during cooling. See page 26.