25

DHUM

R

R

DHUM

HUMIDISTAT

MOTOR

CONTROL BOARD

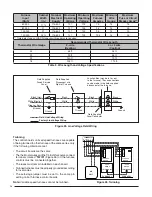

Figure 24. DHUM Wiring Confi guration 7

Autostaging for Two-Stage Thermostats

The Autostage setting on the furnace control board (Figure

31) is disabled when shipped from the factory. This feature

will be not used when paired with a two-stage thermostat.

The Autostage Jumper (P7) must be kept on the

NONE

setting to allow the thermostat to adjust stages.

Please note that on certain thermostats, even without

the Autostage jumper in the “LONG” position,

W1

and

W2

may be energized at exactly the same time when

a recovery from a set-back begins, the user adjusts the

set point, or the system is powered on. If

W1

and

W2

are

energized at exactly the same time for any reason, the

control will operate in the Autostage “LONG” (12 minute)

mode. If the Autostage jumper is in the “NONE” position

and Autostaging is activated unexpectedly for any of the

reasons listed, it will return to normal, staged operation

after the completion of the heating cycle.

Dehumidifi cation Options

Both motor control boards (Figures 29 & 30, page 41)

have a DHUM connection that causes the system to

increase the amount of humidity that is removed from the

circulating air. This is accomplished by reducing the CFM

and allowing the cooling coil to become colder. This will

only occur when there is a call for cooling.

There are many ways that this can be electrically wired:

1. If the room thermostat incorporates a humidity sensor

and

DHUM

output, connect the

DHUM

on the thermostat

to the

DHUM

terminal on the motor control board

(Figure 24).

2. If using a separate humidistat, connect the

DHUM

and

R

terminals on the humidistat to the

DHUM

and

R

terminals on the motor control board.

In this option, the

DHUM

output of the humidistat must

be set to be normally open and closed when there is

a call for humidifi cation.

3. If a humidistat is not available, it is an acceptable option

to connect the

R

and

DHUM

terminals on the motor

control board together with a fi eld supplied wire. This

option causes the blower to run at a reduced CFM for

10 minutes after a call for cooling.

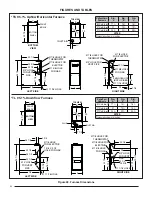

IMPORTANT NOTE: An electrical disconnect must be

installed readily accessible from and located within

sight of the furnace. See Figure 25 (page 26) or the

wiring diagram label inside of the control door. Any

other wiring methods must be acceptable to authority

having jurisdiction.

CAUTION:

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause

improper and dangerous operation. Verify

proper operation after servicing.

IMPORTANT NOTE:

Proper line voltage polarity must

be maintained in order for the control system to

operate correctly. Verify the incoming neutral line is

connected to the white wire and the incoming “hot”

line is connected to the black wire. The furnace will not

operate unless the polarity and ground are properly

connected as shown in Figure 25.

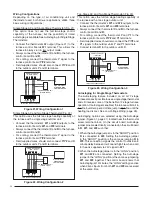

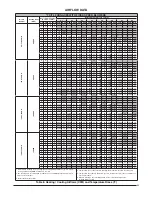

Low Voltage Wiring

The thermostat must be installed according to the

instructions supplied by the thermostat manufacturer.

Low voltage connections (24 VAC) from the thermostat

are wired to the terminal strip on the integrated control

in the furnace. Recommended minimum wire gauge for

thermostat wiring is shown in Table 5.

The thermostat must not be installed on an outside wall or

any other location where its operation may be adversely

affected by radiant heat from fi replaces, sunlight, or lighting

fi xtures, and convective heat from warm air registers or

electrical appliances.

IMPORTANT NOTE:

Set the heat anticipator according

to the instructions supplied by the thermostat

manufacturer.

To determine the heat anticipator setting:

1. Add the current draw of the system components; or

2. Measure the current fl ow on the thermostat

R-W

circuit

after the circulating blower motor has started.

Grounding

WARNING:

To minimize personal injury, the furnace cabinet

must have an uninterrupted or unbroken electrical

ground. The controls used in this furnace

require an earth ground to operate properly.

Acceptable methods include electrical wire or

conduit approved for ground service. Do not

use gas piping as an electrical ground!

Line Voltage Wiring

It is recommended that the line voltage (115 VAC) to

the furnace be supplied from a dedicated branch circuit

containing the correct fuse or circuit breaker for the furnace

(Table 5, page 26).