8

COMBUSTION AIR REQUIREMENTS

General Information

WARNING:

Furnace installation using methods other than

those described in the following sections must

comply with the National Fuel Gas Code (NFGC)

and all applicable local codes.

• Instructions for determining the adequacy of combustion

air for an installation can be found in the current revision

of the NFGC (ANSI Z223.1 / NFPA54).

Consult local

codes for special requirements

. These requirements

are for US installations as found in the NFGC.

• The requirements in Canada (B149.1) are structured

differently. Consult with B149.1 and local code offi cials

for Canadian installations.

This condensing furnace is certifi ed for installation either as

a Direct Vent (2-pipe) or Conventional (1-pipe) appliance.

Direct Vent appliances draw combustion air from the

outdoors and vent combustion products back outside.

Installation with air taken from around the furnace is often

referred to as Conventional installation - i.e. only the vent

(exhaust) pipe is provided.

Provisions must be made during the installation of

this furnace that provide an adequate supply of air for

combustion. The combustion air from the outside needs

to be clear of chemicals that can cause corrosion. The

inlet pipe should not be placed near corrosive chemicals

such as those listed on page 6.

Another important consideration when selecting one or

two pipe installation is the quality of the Indoor air which

can sometimes be contaminated with various household

chemicals . These chemicals can cause severe corrosion

in the furnace combustion system.

A 2-pipe installation

has the additional advantage that it isolates the system

from the effects of negative pressure in the house.

CAUTION:

Exhaust fans, clothes dryers, fi replaces and

other appliances that force air from the house

to the outdoors can create a negative pressure

inside the house, resulting in improper furnace

operation or unsafe conditions such as fl ame roll

out. It is imperative that suffi cient air exchange

with the outdoors is provided to prevent

depressurization. Additional information about

how to test for negative pressure problems can

be found in the NFGC.

NOTE

: Air openings on top of the furnace and openings

in closet doors or walls must never be restricted. If the

furnace is operated without adequate air for combustion,

the fl ame roll-out switch will open, turning off the gas

supply to the burners. This safety device is a manually

reset switch.

DO NOT install jumper wires across

these switches to defeat their function or reset a

switch without identifying and correcting the fault

condition.

If a switch must be replaced, use only the

correct sized part specifi ed in the Replacement Parts

List provided online.

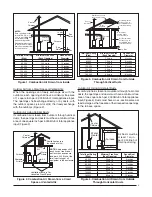

Direct Vent Furnaces

Direct Vent (2-pipe) furnaces draw combustion air directly

from the outdoors and then vent the combustion products

back outside, isolating the entire system from the indoor

space. It is important to make sure that the whole system

is sealed and clearances to combustibles are maintained

regardless of the installation being in a confi ned or

unconfi ned space.

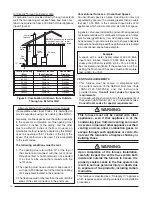

Conventional Furnaces - Confi ned Spaces

A confi ned space is an area with volume less than 50

cubic feet per 1,000 Btuh of the combined input rates of

all appliances drawing combustion air from that space.

Furnace closets, small equipment rooms and garages are

confi ned spaces. Furnaces installed in a confi ned space

which supply heated air to areas outside the space must

draw return air from outside the space and must have

the return air ducts tightly sealed to the furnace. Ducts

must have cross - sectional area at least as large as

the free area of their respective openings to the furnace

space. Attics or crawl spaces must connect freely with

the outdoors if they are the source of air for combustion

and ventilation.

The required sizing of these openings is determined by

whether inside or outside air is used to support combustion,

the method by which the air is brought to the space, and

by the total input rate of all appliances in the space. In

all cases, the minimum dimension of any combustion air

opening is 3 inches.

Air From Inside

If combustion air is taken from the heated space, the two

openings must each have a free area of at least one square

inch per 1,000 Btuh of total input of all appliances in the

confi ned space, but

not less than

100 square inches of

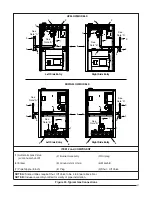

free area (Figure 1, page 10)

.

Example

:

If the combined input rate of all appliances is less

than or equal to 100,000 Btuh, each opening must

have a free area of at least 100 square inches. If the

combined input rate of all appliances is 120,000 Btuh,

each opening must have a free area of at least 120

square inches.