24

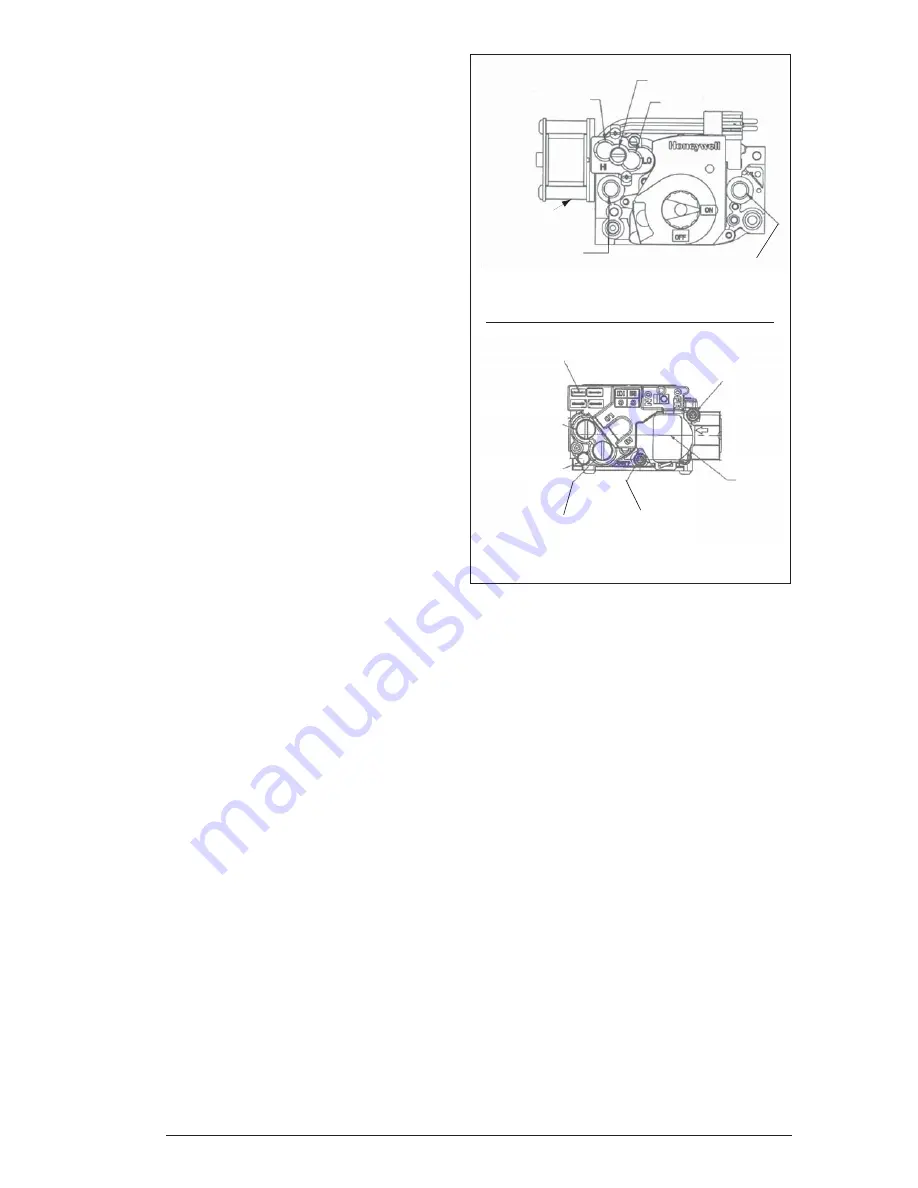

Figure 20. Gas Valve

(Honeywell shown)

(White Rodgers shown)

(4) QUICK DISCONNECT TERMINALS

1ST STAGE

REGULATOR COVER

REGULATOR ADJUST

BENEATH THIS SCREW

VENT (.330 DIA.

+DFT. POST)

ACCEPTS 5/16” HOSE

CONNECTION

2ND STAGE

REGULATOR COVER

REGULATOR ADJUST

BENEATH THIS SCREW

OUTLET PRESSURE

POST SET SCREW: 3/32”

HEX HEAD (.339 DIA. +DFT.)

ACCEPTS 5/18” HOSE CONNECTION

CONTROL

LABEL

INLET PRESSURE POST

SET SCREW: 3/32” HEX HEAD

(.339 DIA. +DFT.)

ACCEPTS 5/18”

HOSE CONNECTION

VENT FITTING FOR 90 PLUS

EFFICIENT APPLIANCES

LOW STAGE ADJUSTMENT

UNDER VENT CAP

HIGH STAGE ADJUSTMENT

UNDER VENT CAP

OUTLET PRESSURE TAP

1/8 NPT

INLET PRESSURE TAP

1/8 NPT

2-STAGE

OPERATOR

altitude is detailed in the installation instructions

provided with the conversion kit. Approved

conversion kits are listed below.

United States LP/Propane Gas Sea Level and

High Altitude Conversion Kit - P/N 904404

This kit is for LP/propane conversion in the

United States at altitudes between zero and

10,000 ft. above sea level. Follow the installation

instructions supplied with the kit for proper

installation.

Canadian LP/Propane Gas Sea Level and High

Altitude Conversion Kit - P/N 904405

This kit is for LP/propane conversions in Canada

at altitudes between zero and 4500 ft. above sea

level. Follow the installation instructions supplied

with the kit for proper installation.

IMPORTANT NOTE: When converting a low

NOx furnace from Natural Gas to LP/Propane

Gas, it is necessary to remove the NOx baffl es

from the furnace.

HIGH ALTITUDE CONVERSION

High Altitude Application

Conversion of this furnace to replace the

pressure switch or to utilize LP/propane gas

must be made by qualifi ed service personnel,

using factory authorized or approved parts. High

altitude applications with this furnace can be fi eld

performed by a simple adjustment of manifold

pressure, and if necessary changing the orifi ces

and the vent pressure switch. The changes

required depend on the installation altitude and

the heating value of the gas. The gas heating

value based on sea level can be obtained from

your local gas utility. The heating value of gas at

high altitude is always lower than the sea level

heating value. The heating values used in Tables

10 and 11 are based on sea level values.

Pressure Switch Conversion for

High Altitude Applications

These units are factory equipped to operate

between zero and 8000 feet above sea level.

For higher altitude applications, you may need

to replace the vent pressure switch in addition

to the main gas burner orifi ces.

Natural Gas High Altitude

Conversion

All factory shipped furnaces are ready to operate

between zero and 4999 ft. above sea level. For

higher altitudes (between 5000 and 10,000 ft.

above sea level), conversion can be achieved

simply by adjusting the furnace manifold pressure

as shown in Tables 6 and 7.

LP/Propane Gas Sea Level and

High Altitude Conversion

Conversion to LP/propane gas can be

accomplished by fi rst replacing the natural gas

orifi ces with the appropriate LP/propane orifi ces

shown in Table 8 or 9 Note: for installations

between zero and 5000 ft. above sea level, refer to

Table 8. For installations above 5000 ft. above sea

level, refer to Table 9. After changing the orifi ces,

use Tables 7 and 9 to determine the appropriate

manifold pressure for your installation.

Conversion to LP/propane, sea level, and high