7

7. Feed the 10” piece of soft tubing through

the round hole located in the right side of

the cabinet wrapper Note: A downward

slope must be maintained on the tube as

it is routed through the furnace (when the

furnace is in the horizontal position).

8. Assemble the 10” piece of soft tube to 5”

tall end of the hard (J) tube to the end of

the 10” soft tube located outside of the

furnace. Secure the connection using one

of the clamps that was removed, from the

“J” trap. Secure the connection with the 7/8”

hose clamp.

9. Reassemble the 30” piece of soft tubing

removed from the factory installed “J” tube

drain trap to the 2’ tall end of the modifi ed

“J” tube drain trap.

Note:

Ensure the clamps in step 7 and 8 are

securely tightened in order to avoid any con-

densate leakage.

Note:

PVC “T” drain assembly must be installed

so that condensate does not get into the induced

draft blower.( refer to Figure 2).

Note:

To avoid condensate freezing in the drain

trap assembly and tubing, insulate around the

drain trap assembly and all tubing located in

unconditioned space.

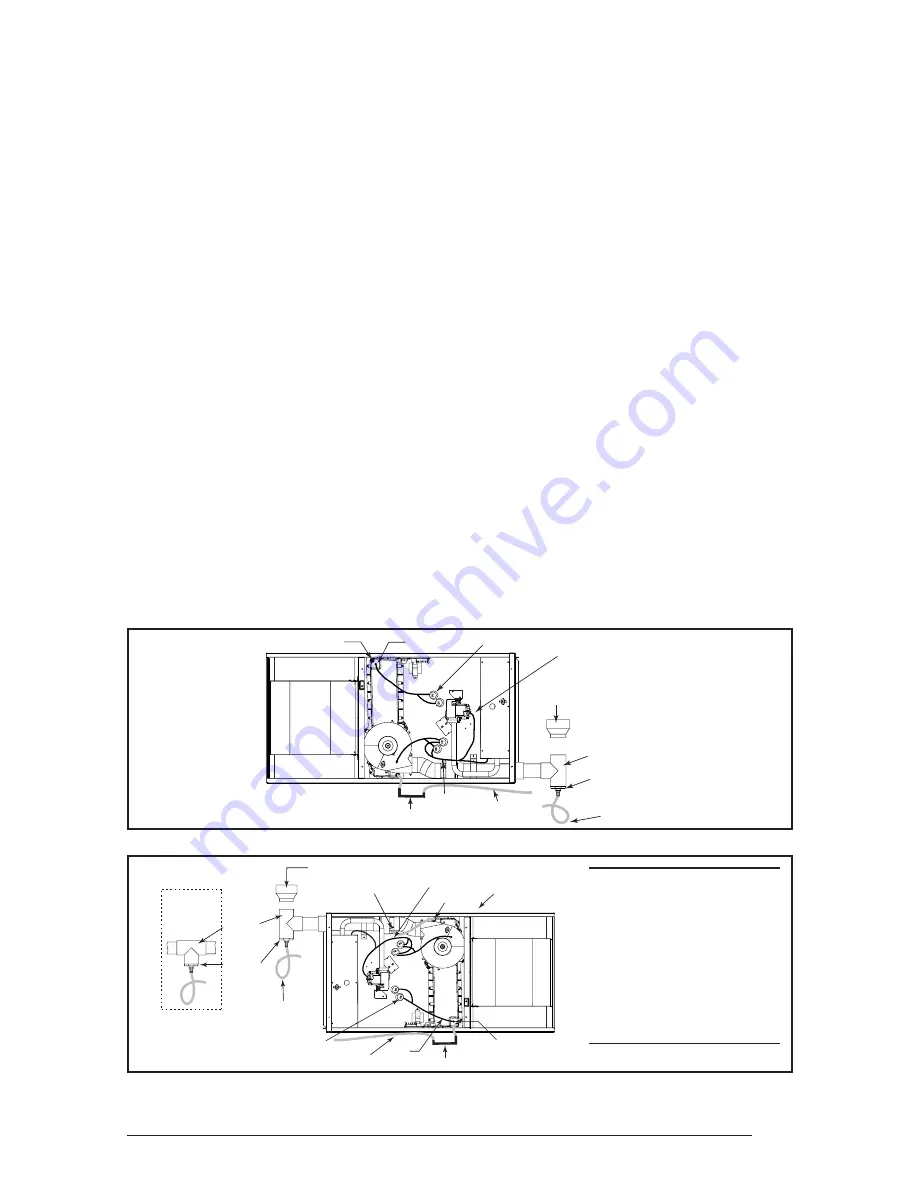

Figure 2. 90+ Upfl ow Converted for Horizontal Installation (Horizontal Right)

5/8" Vinyl Cap

1/4" Vinyl Cap

Drain Trap

1/2" Vinyl

Cap

Soft

Tubing

PVC Tee

Soft Tubing

Looped to Provide

a Drain Trap

3" to 2"

Reducer

(Optional)

PVC Reducer

Bushing

Pressure Switch

Grey

Tubing

Soft Tubing

1/4" Vinyl Cap

Grey

Tubing

Drain Trap

Soft

Tubing

PVC Tee

Soft Tubing

Looped to Provide

a Drain Trap

3" to 2"

Reducer

(Optional)

Drainage Port

is Downward

Reducer

Bushing

Alternative

for

Horizontal

Vent

Pressure

Switch

Pressure Switch

(Condensate)

Vinyl Cap

Figure 3. 90+ Upfl ow Converted for Horizontal Installation (Horizontal Left)

Conversion of the *TE Upfl ow Furnace for a

Horizontal Left Installation.

Refer to Figure 3.

1. Remove the hard “J” tube drain trap as-

sembly.

2. If fi eld supplied parts are used, disconnect

both soft tubes from the hard “J” tube drain

trap after loosing 7/8” clamps. Shorten long

side of the “J” trap by 8-1/2”.

3. Feed the 10” piece of soft tubing through

the round hole located in the left side of

the cabinet wrapper. Note: A downward

slope must be maintained on the tube as

it is routed through the furnace (when the

furnace is in the horizontal position).

4. Assemble the 5” tall end of the hard “J”

tube to the end of the 10” soft tube located

outside of the furnace. Secure the connec-

tion using one of the 7/8” hose clamps that

were removed from the “J” trap.

5. Assemble the 30” piece of soft tubing that

was removed from the “J” trap to the 2” tall

end of the modifi ed “J” drain trap. Secure

the connection with the 7/8” hose clamp.

NOTE:

To avoid condensate freezing in the drain

trap assembly and tubing, insulate around the

drain trap assembly and all tubing located in

unconditioned space.

NOTE:

When converting the

furnace, to horizontal left,

ensure that the drainage port

on the in-line drain assembly

is downward as shown in

this fi gure. If the in-line drain

assembly is not rotated, then

the furnace may not drain

properly.