4

5

Chimney connector must be in good condition

and kept clean.

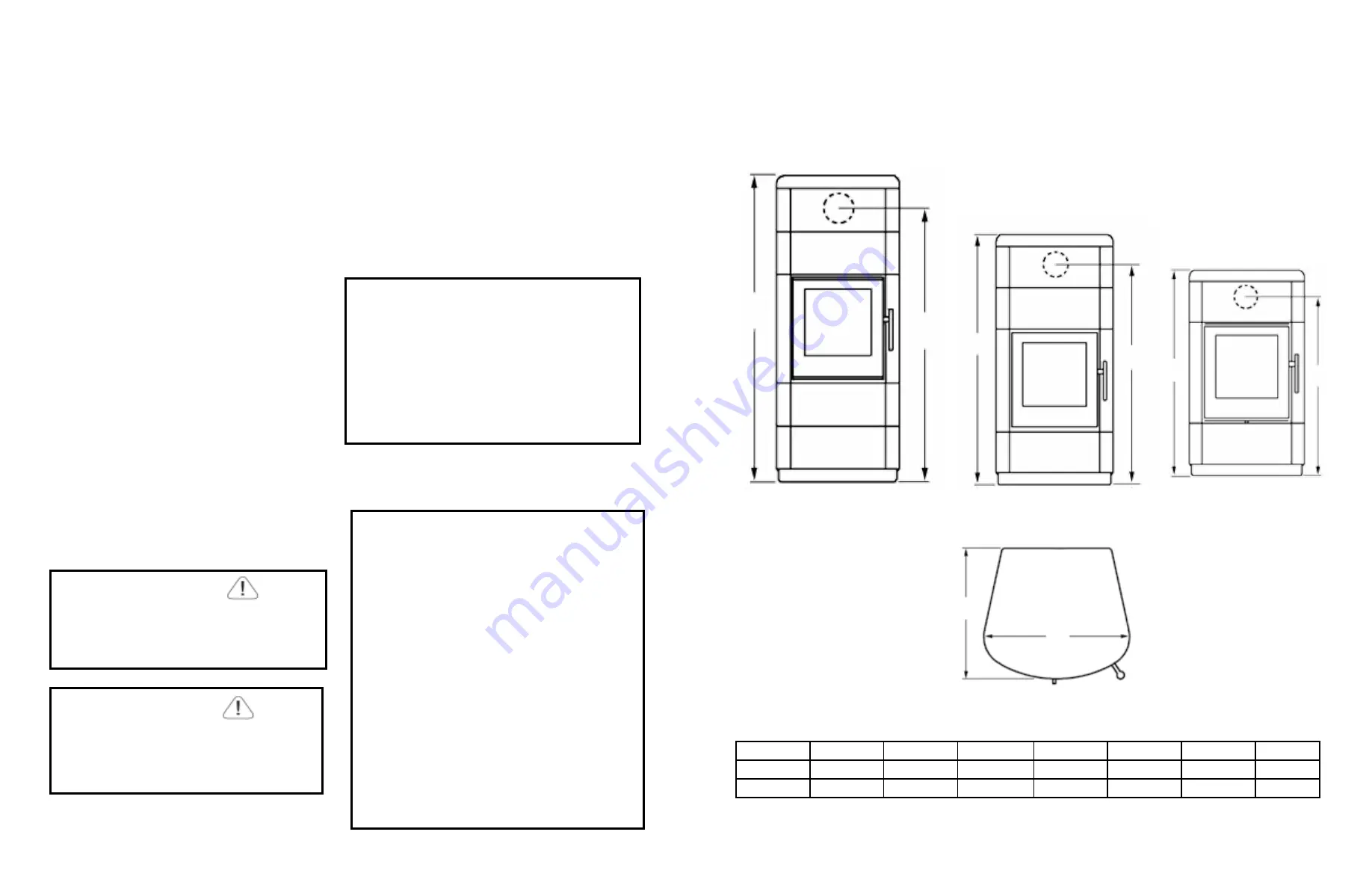

Marcello Soapstone Stove Dimensions

Marcello 140

Marcello 120

Marcello 110

A

B

C

D

E

F

G

H

21.65 in.

18.9 in.

55.12 in.

48.82 in.

47.24 in.

40.95 in.

39.37 in.

33.07 in.

550 mm

480 mm

1400 mm

1240 mm

1200 mm

1040 mm

1000 mm

840 mm

•

Avoid creating a low pressure condition in the

room where the stove is operating. Be aware

that operation of an exhaust fan or clothes dryer

can create a low pressure area and consequently

promote flow reversal through the stove and

chimney system. The chimney and building,

however, always work together as a system -

provision of outside air, directly or indirectly

to an atmospherically vented appliance will not

guarantee proper chimney performance. Consult

your local Norsk Kleber authorized dealer

regarding specific installation or performance

issues.

•

Never fire while the stove door is open.

•

In case of soot fire: close the stove’s draft

adjustment immediately and call 911.

•

WARNING: THIS WOOD-BURNING HEATER

HAS A MANUFACTURER-SET MINIMUM LOW

BURN RATE THAT MUST NOT BE ALTERED.

IT IS AGAINST FEDERAL REGULATIONS

TO ALTER THIS SETTING OR OTHERWISE

OPERATE THIS WOOD HEATER IN A

MANNER INCONSISTENT WITH OPERATING

INSTRUCTIONS IN THIS MANUAL.

•

Check building codes.

When installing, operating and maintaining your

Marcello model, follow the guidelines presented

in these instructions, and make them available to

anyone using or servicing the stove. In the U.S.,

guidelines established by UL 1777, the National

Fire Protection Association’s Code, NFPA 211,

Standards for Chimneys, Stoves, Vents and Solid

Fuel Burning Appliances, or similar regulations,

may apply to the installation of a solid fuel burning

appliance in your area. For further information on

using your heater safely, obtain a copy of the NFPA

publication “Using Coal and Wood Stoves Safely,”

NFPA No. HS-8-1974, available from NFPA 470

Atlantic Ave. Boston, MA 02210.

In Canada, the guidelines are established by

ULC-S635, and the CSA Standard, CAN/CSA-

B365-M93, Installation Code for Solid-Fuel-

Burning Appliances and Equipment.

Always consult your local building inspector

or authority having jurisdiction to determine

what regulations apply and what permits may be

required before installation of a solid fuel-burning

appliance.

California Safety Information

WARNING

This product and the fuels used to operate this

product (wood), and the products of combustion of

such fuels, can expose you to chemicals including

carbon black, which is known to the State of

California to cause cancer, and carbon monoxide,

which is know to the State of California to cause

birth defects or other reproductive harm. For more

information go to: www.P65Warnings.ca.gov

Proposition 65 Warning:

Fuels used in gas,

woodturning or oil fired appliances, and the

products of combustion of such fuels, contain

chemicals known to the State of California to cause

cancer, birth defects and other reproductive harm.

California Health & Safety Code Sec. 25249.6

C

D

F

G

A

E

H

B

WARNING

If glass requires replacement only use: Schott or

Nippon ceramic glass, with a thickness of 5 mm.

WARNING

Summary of Contents for Marcello

Page 10: ...Marcello 140 Exploded View ...