10-10

Page 27

2008-12-03

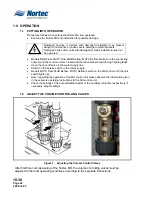

Figure 8. Mounting Process – Step 8

Fix hydraulic unit to the water tub and the cross beam using four hexagon socket screws 1/4 UNC x 1/2"

and washers.

Important

:

Remove the closing plug “H” from the circulation pump inlet

before mounting

the hydraulic units MHB Reflow or MHTC Reflow.

Summary of Contents for MH Series

Page 1: ...2544832 A MH Series EVAPORATIVE HUMIDIFIER COOLER Installation Manual TM ...

Page 5: ...10 00 Page 1 2008 12 03 10 00 INTRODUCTION ...

Page 21: ...10 10 Page 17 2008 12 03 10 10 INSTALLATION ...

Page 37: ...10 20 Page 33 2008 12 03 10 20 PLUMBING ELECTRICAL INSTALLATION ...

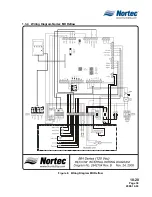

Page 42: ...10 20 Page 38 2008 12 03 1 3 3 Wiring Diagram Nortec MH Flow Figure 7 Wiring Diagram MH Flow ...

Page 44: ...10 20 Page 40 2008 12 03 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 45: ...10 30 Page 41 2008 12 03 10 30 OPERATION ...

Page 48: ...10 30 Page 44 2008 12 03 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 49: ...10 40 Page 45 2008 12 03 10 40 MAINTENANCE TROUBLESHOOTING ...