39

ML Solo - Direct room humidification

ML Systems

2591584_EN_1706

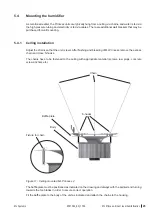

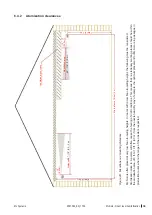

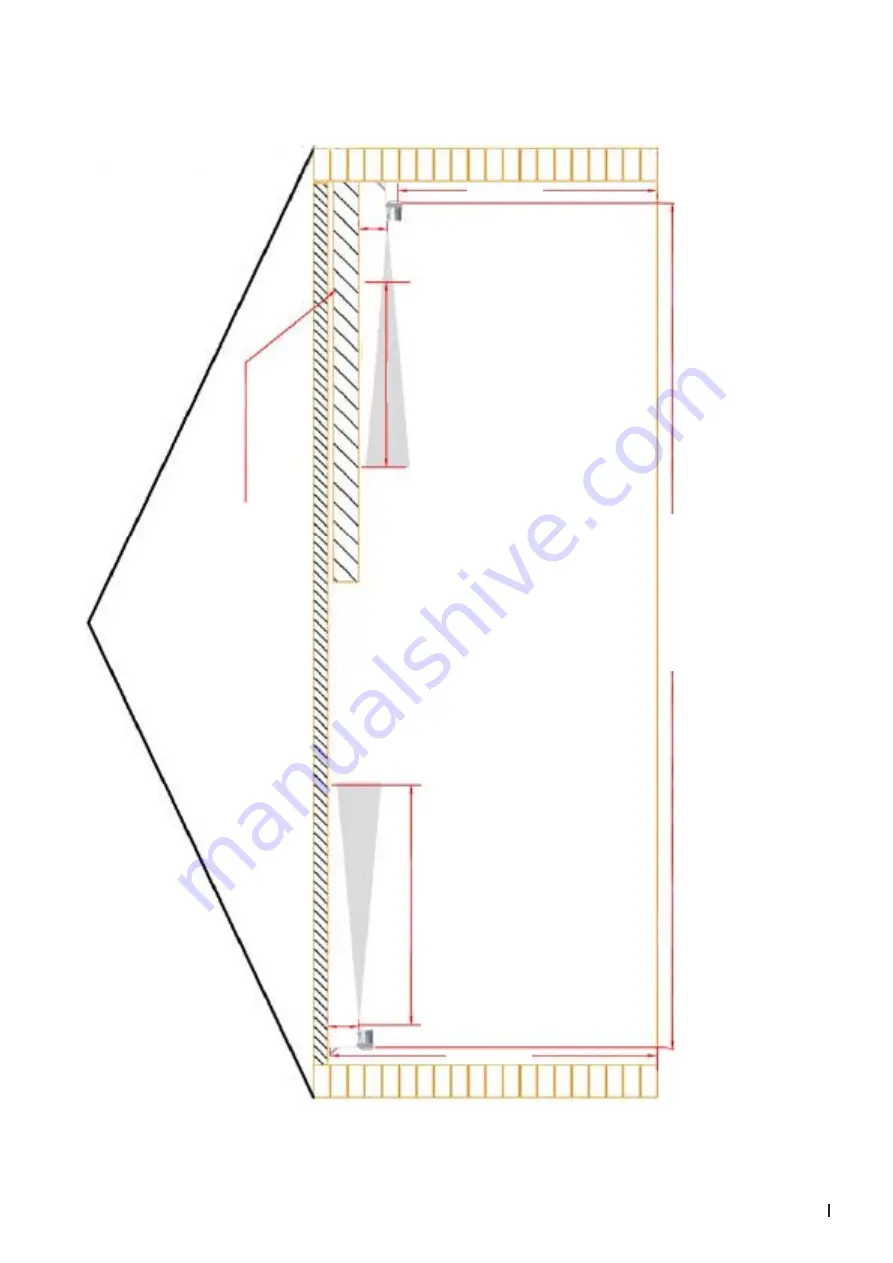

6.4.2 Atomization clearances

8 feet (2.5 m)

7 feet (2.2 m)

10"

(0.25 m)

10"

(0.25 m)

Distance

98" - 1

18" (2.5 - 3 m)

Min. distance 19 feet (6 m)

Ventilation pipes, if any

Atomization area

40" - 1

18" (1 - 3 m)

Figure

20:

Miscellaneous mounting distances

ML

Solo is often placed at very low floor-to-ceiling heights. In rooms with a low floor-to-ceiling height, the following must be considered:

Atomization

close

to

a

person

will

often

cause

the

feeling

of

draft

conditions.

This

means

that

no

stationary

workin

g

places

should

be

within

the

atomization

area

of

3

ft.

to

10

ft.

(1

to

3

m)

from

the

nozzle

head.

By

way

of

example,

the

optimum

placement

for

ML

Solo

is

in

passages

in

production rooms where the range of the nozzle is respected.