10-10

Page 14

2008-10-01

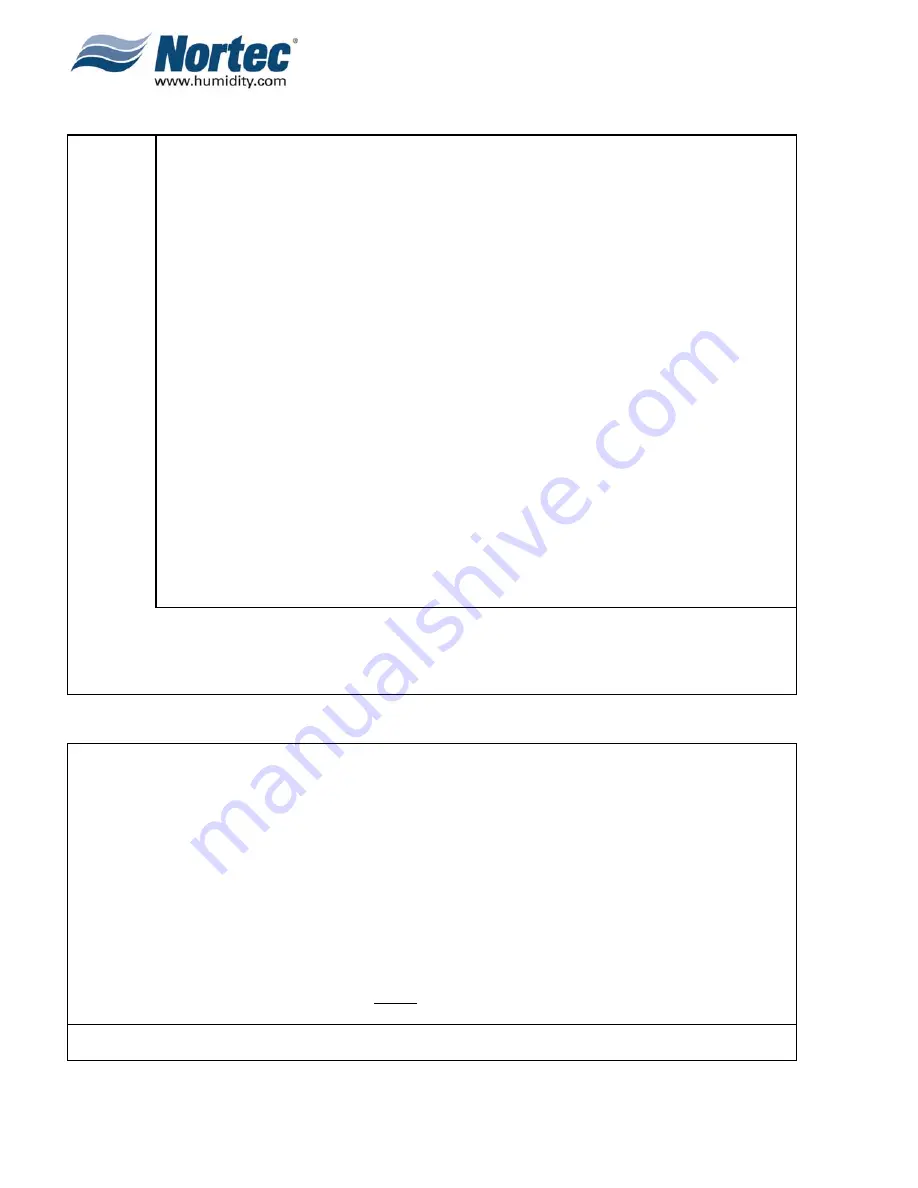

Table 1. Outdoor/Indoor Relative Humidity Conversion Chart

Table 2. Load Calculation Summary Sheet

Out

d

oor re

lative

humidity

100%

2

4

5

6

7

9

12

17

19

23

29

36

43

52

95%

2

3

4

6

7

9

12

16

17

22

28

34

41

50

90%

2

3

4

5

6

8

11

15

16

21

26

31

39

48

85%

2

3

4

5

6

8

11

14

15

20

24

29

37

45

80%

2

3

4

5

6

7

10

13

15

19

23

27

35

42

75%

2

3

4

4

5

7

10

12

14

18

22

26

33

39

70%

1

2

3

4

5

6

9

11

13

17

20

24

31

36

65%

1

2

3

4

4

5

8

10

12

15

19

23

29

34

60%

1

2

3

3

4

5

7

9

11

14

17

21

26

31

55%

1

1

3

3

4

4

7

8

10

13

16

19

24

29

50%

1

1

2

3

3

4

6

8

9

12

14

18

22

26

45%

1

1

2

3

3

4

6

7

8

11

13

16

20

24

40%

1

1

2

2

3

4

5

7

7

10

12

14

18

21

35%

1

1

2

2

2

4

5

6

6

9

10

12

15

18

30%

0

1

2

2

2

3

4

5

6

7

9

11

13

15

25%

0

1

1

1

2

3

3

4

5

5

7

9

11

13

20%

0

1

1

1

2

2

3

3

4

5

5

7

9

10

15%

0

0

1

1

1

1

2

3

3

4

4

5

6

8

10%

0

0

0

1

1

1

2

2

2

3

3

3

4

6

5%

0

0

0

0

0

0

1

1

1

2

2

2

3

3

0%

0

0

0

0

0

0

0

0

0

0

0

0

0

0

-20°

-10°

-5°

0°

+5°

+10°

+15°

+20°

+25°

+30°

+35°

+40°

+45°

+50°

Outdoor temperature

Chart shows what the residual indoor RH would be at 70°F under varying outdoor conditions if a proper humidification

system were not installed in the building. Studies indicate that the recommended RH should be between 40% and 60%

for optimum benefits to the occupants.

Determine the moisture required in the space (Table 3)

Grains from Table 3 at space temp. ______ x Indoor RH

= A ______ gr/ft

3

Determine the moisture level of incoming air (Table 4)

Grains from Table 4 at space temp. ______ x Outdoor RH

= B ______ gr/ft

3

Therefore: moisture to be added: (moisture) M - A - B ______ gr/ft

3

→

M ______ gr/ft

3

Determine the volume of air to be humidified. Choose the largest

value.

1.

Natural ventilation: Volume x number of air changes.

______ ft

3

/hr

2.

Exhaust air: CFM x 60 min/hr

______ ft

3

/hr

3.

Make-up air: CFM x 60 min/hr

______ ft

3

/hr

→

C ______ ft

3

/hr

Therefore:

Gross humidification load = L (load) = MxC = ______ lbs/hr

→

L ______ lbs/hr

7,000

NOTES:

1. 7,000 grains = 1 pound

2. If HVAC system uses economizer cycle, check load using formula 6.

Summary of Contents for NHPC

Page 1: ...2538144 B NH Series NHTC NHPC ELECTRODE STEAM HUMIDIFIER Engineering Manual TM ...

Page 9: ...10 00 Page 1 2008 10 01 10 00 INTRODUCTION ...

Page 10: ...10 00 Page 2 2008 10 01 Figure 1 NHTC ...

Page 13: ...10 00 Page 5 2008 10 01 Figure 2 Optimum Boiling Time Figure 3 Conductivity ...

Page 18: ...10 00 Page 10 2008 10 01 Figure 6 Typical NHRS Installation Sheet 1 of 2 ...

Page 19: ...10 00 Page 11 2008 10 01 Figure 7 Typical NHRS Installation Sheet 2 of 2 ...

Page 20: ...10 10 Page 12 2008 10 01 10 10 HUMIDITY STEAM ABSORPTION AND DISTRIBUTION ...

Page 35: ...10 10 Page 27 2008 10 01 Figure 2 Psychrometric Chart ...

Page 64: ...10 10 Page 56 2008 10 01 Figure 30 NORTEC OnLine Monitoring ...

Page 71: ...10 20 Page 63 2008 10 01 10 20 SPECIFICATIONS ...

Page 81: ...10 30 Page 73 2008 10 01 10 30 SUBMITTALS ...

Page 86: ...10 30 Page 78 2008 10 01 Figure 2 Primary Line Voltage Wiring to Unit ...

Page 87: ...10 30 Page 79 2008 10 01 Figure 3 Physical Data NHTC NHPC 005 030 ...

Page 88: ...10 30 Page 80 2008 10 01 Figure 4 Physical Data NHTC NHPC 050 100 ...

Page 89: ...10 30 Page 81 2008 10 01 Figure 5 Physical Data NHTC NHPC 150 200 ...

Page 96: ...10 30 Page 88 2008 10 01 Figure 12 In Duct AHU Installation With Mounting Frame Installation ...

Page 98: ...10 30 Page 90 2008 10 01 Figure 13 In Duct AHU Installation With Mounting Frame Installation ...

Page 100: ...10 30 Page 92 2008 10 01 Figure 16 Atmospheric SAM e Adapter Dimensions ...

Page 101: ...10 30 Page 93 2008 10 01 Figure 17 Atmospheric Steam Header and Adapter Configuration ...

Page 102: ...10 30 Page 94 2008 10 01 Figure 18 Physical Data for Remote Mounted Blower Pack ...

Page 103: ...10 30 Page 95 2008 10 01 Figure 19 Physical Data Units with Optional Built On Blower Packs ...

Page 104: ...10 30 Page 96 2008 10 01 Figure 20 Physical Data Units with Optional Built On Blower Packs ...