10-10

Page 30

2008-10-01

B.

CALCULATING THE DOWN STREAM HUMIDITY LEVEL

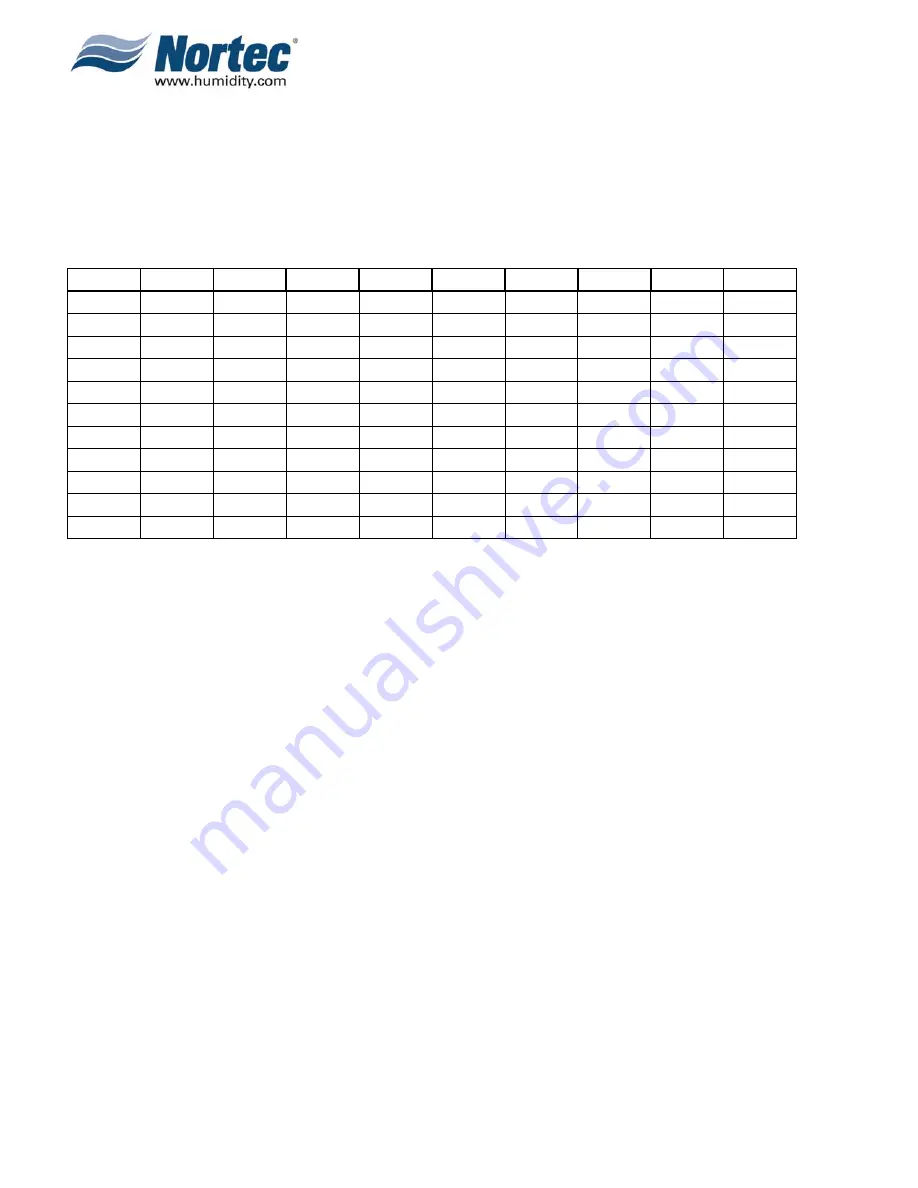

(1) Table 10 indicates the amount of water that each 1000 CFM of duct air holds in pounds

of water per hour at various combinations or air temperature and relative humidity.

Subtract the water vapour in the duct air before the steam distributor from the

maximum allowed after the distributor. The chart indicates how many lbs/hr of water

can be added to 1000 CFM of airflow.

Table 10. Water (lbs/hr) Contained in 1000 CFM of Air

(2) The following are two examples:

Example 1:

3000 CFM air handler with 60°F and 30% rh air before the steam distributor.

Calculate the maximum rate of steam addition without exceeding 80% rh in the duct.

60° & 80% = 39.76 lbs/hr

60° & 30% = 14.91 lbs/hr

____________________

24.85 lbs/hr can be added to 1000 CFM

x 3 (3000CFM)

____________

74.55 lbs/hr can be added to 3000 CFM

If the load calculation of this system requires a 100 lbs/hr unit, then due to the above

possible conditions, the project requires a modulating high limit humidistat to limit the

humidifier output to a maximum of 74 lbs/hr and maintain 80% rh.

Example 2:

Humidification load is 30 lbs/hr. To avoid exceeding 80% rh in the duct, calculate the

minimum allowable CFM at 55°F. Duct conditions are 55°F and 50% rh.

55° & 80% = 33.53 lbs/hr

55° & 50% = 20.95 lbs/hr

____________________

12.57 lbs/hr can be added to 1000 CFM

(30 lbs/hr ÷ 12.57) x 1000 = 2386 CFM minimum

°F

10%

20%

30%

40%

50%

60%

70%

80%

85%

50

3.52

7.04

10.56

14.06

17.60

21.12

24.65

26.16

29.92

55

4.19

8.38

12.57

16.76

20.95

25.14

29.33

33.52

35.62

60

4.97

9.94

14.91

19.88

24.85

29.82

34.79

39.76

42.25

65

5.85

11.74

17.61

23.48

29.35

35.22

41.09

46.96

49.73

70

6.94

13.80

20.82

27.78

34.70

41.64

48.58

55.52

58.99

75

8.10

16.20

24.30

32.40

40.50

48.60

56.70

64.80

68.85

80

9.46

18.92

28.36

37.84

47.30

56.76

66.22

75.68

80.41

85

11.03

22.08

33.09

44.12

55.15

66.18

77.21

88.24

93.75

90

12.80

25.60

38.40

51.20

64.00

76.80

89.60

102.4

108.80

95

14.81

29.62

44.43

59.24

74.05

88.86

103.67

118.48

125.89

100

17.10

34.20

51.20

68.40

85.50

102.60

119.60

136.80

145.54

Summary of Contents for NHPC

Page 1: ...2538144 B NH Series NHTC NHPC ELECTRODE STEAM HUMIDIFIER Engineering Manual TM ...

Page 9: ...10 00 Page 1 2008 10 01 10 00 INTRODUCTION ...

Page 10: ...10 00 Page 2 2008 10 01 Figure 1 NHTC ...

Page 13: ...10 00 Page 5 2008 10 01 Figure 2 Optimum Boiling Time Figure 3 Conductivity ...

Page 18: ...10 00 Page 10 2008 10 01 Figure 6 Typical NHRS Installation Sheet 1 of 2 ...

Page 19: ...10 00 Page 11 2008 10 01 Figure 7 Typical NHRS Installation Sheet 2 of 2 ...

Page 20: ...10 10 Page 12 2008 10 01 10 10 HUMIDITY STEAM ABSORPTION AND DISTRIBUTION ...

Page 35: ...10 10 Page 27 2008 10 01 Figure 2 Psychrometric Chart ...

Page 64: ...10 10 Page 56 2008 10 01 Figure 30 NORTEC OnLine Monitoring ...

Page 71: ...10 20 Page 63 2008 10 01 10 20 SPECIFICATIONS ...

Page 81: ...10 30 Page 73 2008 10 01 10 30 SUBMITTALS ...

Page 86: ...10 30 Page 78 2008 10 01 Figure 2 Primary Line Voltage Wiring to Unit ...

Page 87: ...10 30 Page 79 2008 10 01 Figure 3 Physical Data NHTC NHPC 005 030 ...

Page 88: ...10 30 Page 80 2008 10 01 Figure 4 Physical Data NHTC NHPC 050 100 ...

Page 89: ...10 30 Page 81 2008 10 01 Figure 5 Physical Data NHTC NHPC 150 200 ...

Page 96: ...10 30 Page 88 2008 10 01 Figure 12 In Duct AHU Installation With Mounting Frame Installation ...

Page 98: ...10 30 Page 90 2008 10 01 Figure 13 In Duct AHU Installation With Mounting Frame Installation ...

Page 100: ...10 30 Page 92 2008 10 01 Figure 16 Atmospheric SAM e Adapter Dimensions ...

Page 101: ...10 30 Page 93 2008 10 01 Figure 17 Atmospheric Steam Header and Adapter Configuration ...

Page 102: ...10 30 Page 94 2008 10 01 Figure 18 Physical Data for Remote Mounted Blower Pack ...

Page 103: ...10 30 Page 95 2008 10 01 Figure 19 Physical Data Units with Optional Built On Blower Packs ...

Page 104: ...10 30 Page 96 2008 10 01 Figure 20 Physical Data Units with Optional Built On Blower Packs ...