2

support material.

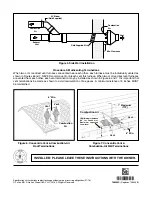

imporTanT: Make sure the termination height is above

the roof surface or anticipated snow level (12 inches

in U.S.A. or 18 inches in Canada). If the assembly is

too short to meet the height requirement, the 2 pipes

supplied in the kit may be replaced by using the same

diameter, field supplied SDR-26 PVC (D2241) pipe. Do

not expand dimension "D" more than 60 inches. See

Figure 3.

Warning:

do not operate the furnace with rain cap removed.

recirculation of combustion products may

occur, or water may accumulate inside larger

combustion air pipe and flow into the burner

enclosure. Failure to follow this warning could

result in product damage or improper operation,

personal injury or death.

CauTion:

do noT use field supplied couplings to extend

pipes. airflow restriction will occur and the

furnace pressure switch may cause intermittent

operation.

noTe: Instead of cementing the smaller pipe to the rain

cap, a field-supplied stainless steel screw may be used to

secure the 2 components together when field disassembly

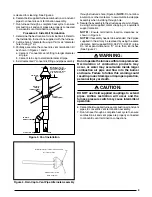

Figure 1. Kit Components

Figure 2. dimensions

B

1 3/16

1 1/2

D

F

A

E

C In. Dia.

KiT no.

a

B

C

d

e

F

904176 (3”) 38 7/8

3

4 1/2

21 1/8

7 3/8

6 1/2

904177 (2”) 33 3/8

2

3 1/2

16 5/8

6 1/4

5 3/4

904952 (2”) 33 /38

2

3 1/2

16 5/8

6 1/4

5 3/4

904953 (3”) 38 7/8

3

4 1/2

21 1/8

7 3/8

6 1/2

inSTallaTion

Warning:

These kits are to be used only for terminating

condensing Category iV furnaces. do noT use

kits to terminate Category i, ii, or iii vent furnaces.

Failure to follow these instructions could result

in fire, personal injury, or death.

The concentric vent is made of pVC. When joining PVC

to PVC, use cement that conforms to ASTM standard

D2564. PVC primer must meet standard ASTM F656.

When joining ABS to ABS, use cement that conforms to

ASTM standard D2235. When joining PVC to ABS, use

cement as specified in procedure from ASTM standard

D3138.

In Canada, all plastic vent pipes and fittings including

any cement, cleaners, or primers must be certified as a

system to ULC S636. However this requirement does not

apply to the finish flanges or piping internal to the furnace.

Consult your furnace installation instructions for the

allowable length and size of the plastic vent pipe. The

concentric vent termination assembly is equal to 4 feet of

3" inlet and outlet pipe, or 3 feet of 2" inlet and outlet pipe.

The concentric vent termination kit is shipped assembled

but not cemented. Disassemble the kit and cement as

shown in Figures 1 and 2.

procedure 1: roof Termination

1. Determine the best location for the termination kit. Refer

to the Installation Instructions supplied with the furnace.

2. Cut one hole, 5” diameter when using a 3" kit or a 4"

diameter hole when using a 2" kit.

3. Partially assemble the concentric vent termination kit

as shown in Figures 1 and 2.

a. Cement Y concentric vent fitting to larger diameter

kit pipe. See Figure 1.

b. Cement rain cap to smaller diameter kit pipe. See

Figure 1.

4. Install cemented Y concentric fitting and pipe assembly

through structure's hole and field supplied roof boot/

flashing. See Figure 3 (page 3).

noTe: Do not allow insulation or other materials to

accumulate inside pipe assembly when installing through

hole.

5. Secure assembly to roof structure as shown in Figure

3 using field supplied metal strapping or equivalent

KiT no.

deSCripTion

uSage

Inside Pipe

Y Concentric

Fitting

Outside Pipe

Rain Cap

904176

Concentric Vent Kit, 3 inch, US

US Only

904177

Concentric Vent Kit, 2 inch, US

US Only

904952 Concentric Vent Kit, 2 inch, US/CAN US/CAN

904953 Concentric Vent Kit, 3 inch, US/CAN US/CAN