13

5. Inspect the unit rating plate for the proper type of

refrigerant and quantity.

6. Weigh in the proper amount of new (or reclaimed)

refrigerant.

Refrigerant Charging

The system refrigerant charge can be checked and

adjusted through the service ports provided at the front

panel of the outdoor unit. Use only gauge lines which have

a Schrader depression device present to actuate the valve.

Air Circulation

Running the Blower Continuously

Set the thermostat’s system mode to OFF and the

thermostat’s fan mode to ON. The blower motor should

run continuously. Check for air delivery at the register(s).

Ensure that there are no obstructions at the registers or

in the ducts.

Turning the Blower Off

Set thermostat’s fan mode to AUTO, the blower will shut

down immediately.

NOTE: If blower is turning opposite of arrow direction, shut

off main power to the unit and switch any two field wires

at the disconnect. DO NOT alter unit wiring.

Continuous low speed fan operation

(Standard Blower)

The air handler is equipped with an option of continuous

low speed fan operation. When G is energized without Y/

Y2, the air handler will operate using the heating speed.

With G & Y/Y1 or Y/Y2 energized, the air handler will

operate in the selected cooling speed (including 40 sec

blower-off delay).

System Cooling

1. Set the thermostat’s system mode to COOL and fan

mode to AUTO. Lower the thermostat’s temperature

mode below room temperature and observe that the

blower energizes. Check the air being discharged at

the register is cooler than room temperature. Verify

unit refrigerant pressures are in order. Blower should

be turning in direction indicated by arrow.

NOTE: DO NOT alter unit wiring. Listen for any unusual

noises. Locate the source and correct as needed.

2. Allow the unit to run for several minutes and then set

the thermostat’s temperature above room temperature.

Verify the blower cycles off with the thermostat.

System Heating

1. Set the thermostat’s system mode to HEAT and the fan

mode to AUTO. Increase the thermostat’s temperature

above room temperature and observe that the blower

energizes. Check the air being discharged at the register

is warmer than room temperature.

2. Allow the unit to run for several minutes and then set

the thermostat’s temperature below room temperature.

Verify the blower cycles off with the thermostat.

Minimum Electric Heat Airflow

The minimum electric heat airflow setting controls the

minimum air flow that will be produced whenever electric

heater kits are used. When the electric heater kit is

energized along with a heat pump, the airflow may be

higher depending on the basic cooling/heat-pump airflow

setting. The minimum electric heat airflow is selected by

the red blower wire on 3-speed models.

Blower Configurations

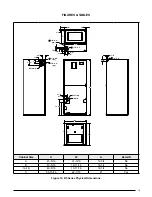

Determining Nominal System Capacity

To select the appropriate airflows for the air handler, the

nominal system capacity must be known. The nominal

system capacity is always the nominal capacity of the

outdoor unit. However, in some situations the nominal

system capacity may not be the same as the nominal

capacity of the air handler. Always refer to the outdoor

unit rating label to determine the nominal system capacity.

NOTE: The CFM values listed in Table 2 (page 17) are

not dependent on duct static pressure. The VSHE motor

automatically compensates for changes in duct static

pressure (within the limits of the motor).

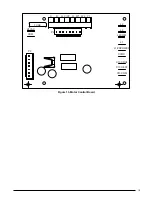

3-Speed Units

The blower speed is preset at the factory for operation

at the same speed for heating and cooling, by using the

jumping terminal on the blower motor and connecting it

to the desired speed with both the red and black wires

connected to the jumping terminal. NOTE: The control

board is programmed with a 40 second off delay in the

cooling mode for optimum system performance and

efficiency.

CAUTION:

To avoid personal injury or property damage,

make sure the motor leads do not come into

contact with any uninsulated metal components

of the unit.

For optimum system performance and comfort, it may be

necessary to change the factory set speed. See Table 2

(page 17) for airflow data. To change the blower speed:

1. Disconnect all electrical power to the unit and remove

the upper door.

2. Remove the black and red wires from the blower motor

jumping terminal. Discard the blower motor jumping

terminal.

3. Connect the heating speed wire (red) and the cooling

speed wire (black) to the desired blower speed marked

on the terminal block of the blower motor.

• Terminal 4 = Hi speed

• Terminal 5 = Med speed

• Terminal 6 = Low speed

4. Replace the upper door and secure it to the unit.

5. Restore power to the unit..

Summary of Contents for B5BM

Page 27: ...27...