4

GENERAL INFORMATION

This appliance has been tested for capacity and efficiency

in accordance with AHRI Standards and will provide

many years of safe and dependable comfort, providing

it is properly installed and maintained. Abuse, improper

use, and/or improper maintenance can shorten the life

of the appliance and create unsafe hazards. Please read

all instructions before installing the unit.

Before You Install this Unit

√

This equipment is securely packaged at the time of

shipment and upon arrival should be carefully inspected

for damage prior to installing the equipment at the job

site. Claims for damage (apparent or concealed) should

be filed immediately with the carrier.

√

The cooling load of the area to be conditioned must be

calculated and a system of the proper capacity selected.

It is recommended that the area to be conditioned be

completely insulated and vapor sealed.

√

Check the electrical supply and verify the power supply

is adequate for unit operation. The system must be wired

and provided with circuit protection in accordance with

local building codes. If there is any question concerning

the power supply, contact the local power company.

√

Verify the static pressure drop of the coil, filter, and

duct work do not exceed the air delivery specs of the

air handler.

Figure 1. Minimum Unit Clearances

INSTALLATION CLEARANCES

Left Side ......... 0 Inches

Right Side ...... 0 Inches

Back ............... 0 Inches

Front ...........

†

See Notes

†

NOTES:

Alcove Installations - Allow 24 in. minimum clearance

from front of unit to nearest wall or partition for servicing.

Recommended clearance is 36 in.

Closet installations - require a return air grill installed in

the door or a partially louvered door across the opening

for proper air circulation. For clearances 6” or greater, the

closet must have an open free area of 235 in

2

minimum.

For special clearances between 1” - 5”, requirements

are a louvered door with a minimum of 250 in

2

(1613

cm

2

) free area. A fully louvered closet door is strongly

recommended for both installation types.

REAR

RIGHT

SIDE

LEFT

SIDE

FRONT

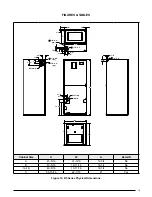

Locating the Air Handler

• Survey the job site to determine the best location for

mounting the unit. Consideration should be given to

availability of electric power, service access, and noise.

• The dimensions of the room or alcove must be able

to accommodate the overall size of the unit and the

installation clearances listed in Figure 1. Physical

dimensions for this air handler are also shown in Figure

11 (page 16).

• The air handler should be installed before routing the

refrigerant tubing.

Minimum Clearances

• This appliance must be installed in accordance with

clearances listed in Figure 1. The air handler must be

installed with ample clearance for easy access to the

air filter, blower assembly, heater assembly, controls,

and vent connections.

• Sufficient clearance for unobstructed airflow through a

louvered door must be maintained in order to achieve

rated performance.

Operation of Air Handler During Construction

CAUTION:

Failure to follow these instructions will void the

factory warranty and may significantly reduce

the life or the performance of the air handler,

and/or result in other unsafe conditions. It is

the responsibility of the installing contractor

to insure these provisions are met.

Operating an air handler in a construction environment

can cause the appliance a variety of problems. Proper

use of commercial portable space heating equipment

during construction is recommended. This air handler

may be used during construction if it is not in violation of

any applicable codes and the following criteria are met:

• The installation must meet all applicable codes and

be permanently installed according to the instructions

supplied with the air handler. This includes electrical

supply, gas supply, and duct work.

• The air handler must be controlled by a properly installed

thermostat that complies with the current provisions

of the NEC (ANSI/NFPA 70) and all applicable codes

having jurisdiction. Thermostat connections must be

made in accordance with instructions supplied with the

air handler and thermostat. See pages 11 - 12.

• The installation must include a properly installed filter in

the return air system with no by-pass air. The filter must

be inspected frequently and replaced when necessary.

• Return air must be supplied unrestricted and located

such that dust and gases from construction activity are

not introduced into the circulating air system.

• Before occupying the structure: The filter must be

replaced or cleaned, the duct work must be inspected

and cleaned of any construction debris, and the air

Summary of Contents for B5BM

Page 27: ...27...