23

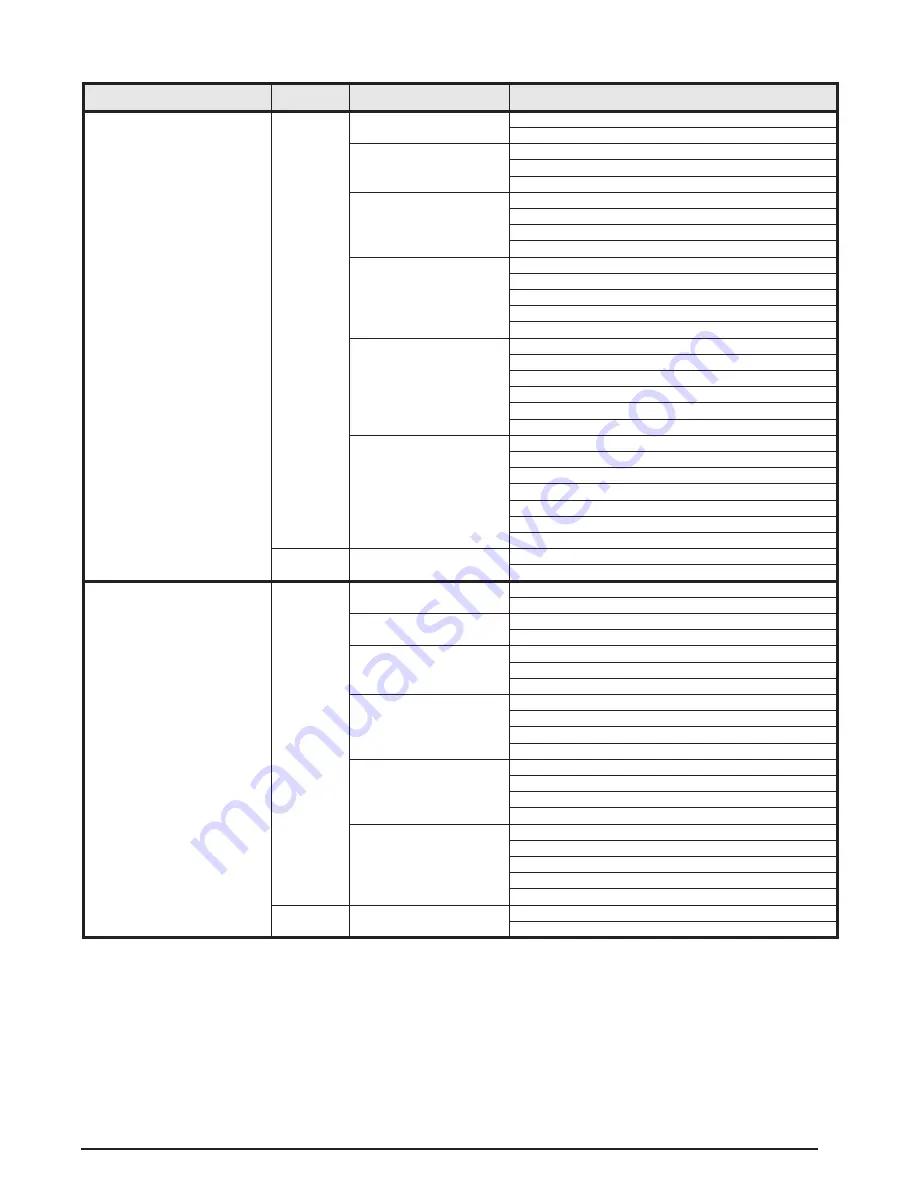

coNtRoL SIGNAL & MoDE

oPERAtIoN

totAL KW

BoARD ActIoN

W1 & W2

EHEAT

ON

5 KW

Stage 1 Heat on instantly

Heat blower on after 3 second delay

10 KW

Stage 1 Heat on instantly

Heat blower on after 3 second delay

Stage 2 Heat on after 5 seconds delay

15 KW

Stage 1 Heat on instantly

Heat blower on after 3 second delay

Stage 2 Heat on after 5 seconds delay

Stage 3 Heat on after 10 seconds delay

20 KW

Stage 1 Heat on instantly

Heat blower on after 3 second delay

Stage 2 Heat on after 5 seconds delay

Stage 3 Heat on after 10 seconds delay

Stage 4 Heat on after 15 seconds delay

25 KW

Stage 1 Heat on instantly

Heat blower on after 3 second delay

Stage 2 Heat on after 5 seconds delay

Stage 3 Heat on after 10 seconds delay

Stage 4 Heat on after 15 seconds delay

Stage 5 Heat on after 20 seconds delay

30 KW

Stage 1Heat on instantly

Heat blower on after 3 second delay

Stage 2 Heat on after 5 seconds delay

Stage 3 Heat on after 10 seconds delay

Stage 4 Heat on after 15 seconds delay

Stage 5 Heat on after 20 seconds delay

Stage 6 Heat on after 25 seconds delay

OFF

—

Heat stages off instantly

Blower off after 15 second delay

W1 & Y/Y2

AUX HEAT

ON

5 KW

Stage 1 Heat on instantly

Cool blower on after 3 second delay

10 KW

Stage 1 Heat on instantly

Cool blower on after 3 second delay

15 KW

Stage 1 Heat on instantly

Cool blower on after 3 second delay

Stage 2 Heat on after 5 seconds delay

20 KW

Stage 1 Heat on instantly

Cool blower on after 3 second delay

Stage 2 Heat on after 5 seconds delay

Stage 3 Heat on after 10 seconds delay

25 KW

Stage 1 Heat on instantly

Cool blower on after 3 second delay

Stage 2 Heat on after 5 seconds delay

Stage 3 Heat on after 10 seconds delay

30 KW

Stage 1 Heat on instantly

Cool blower on after 3 second delay

Stage 2 Heat on after 5 seconds delay

Stage 3 Heat on after 10 seconds delay

Stage 4 Heat on after 15 seconds delay

OFF

—

Heat stages off instantly

Heat blower turns off after 40 second delay

table 13. control Board operation - continued

Summary of Contents for B6BM Series

Page 31: ...31...