7

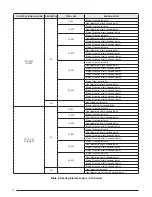

table 1. optional Accessory Kits

DEScRIptIoN

cABINEt SIZE

B

c

Downflow Plenum Connector, 6.25”

913840

914969

Downflow Plenum Connector, 8.25”

913841

914970

Downflow Plenum Connector, 10.25”

913842

914971

Upflow Pedestal Mounting Stand

913872

913873

Downflow Coil Adaptor

919321

919322

*919323

* Use when installing B width coil in C width cabinet

5. Remove the plenum connector and cut out the marked

area of the supply air duct.

NotE:

To allow some clearance for installing the plenum

connector, cut the opening 1/4” larger the actual cutout

drawn.

6. Install the duct connector back in the floor opening with

the bottom tabs extending into the supply air duct. See

.

7. Secure the plenum connector to the wood floor with

appropriate size screws.

8. Bend the connector tabs on the bottom of the plenum

connector upwards and as tight as possible against the

supply air duct. See

.

9. Seal all connections with industrial grade sealing tape

or liquid sealant.

Requirements for sealing ductwork

vary from region to region. consult with local codes

for requirements specific to your area.

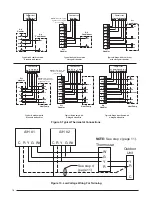

A/c or H/p coil Installation

Approved air conditioning and heat pump system

components are listed on the unit nameplate. To install

the indoor coil:

1. Remove door cover plate, door and coil close-off plate

(with insulation). Discard door cover plate.

2. Upflow Applications: Slide the coil into the track located

in the bottom of the unit.

Downflow Applications: The downflow adaptor must be

used. See

. Install the downflow adaptor and

coil as directed in the instructions supplied with the kit.

3. Reinstall the door and coil close-off plate (with insulation).

NotE:

In downflow applications the door is rotated 180°

so that the refrigerant and condensate lines remain on

the left side.

4. Install the refrigerant and condensate lines as directed

in the instructions supplied with the outdoor unit.

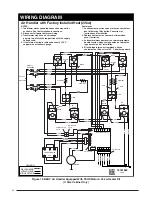

Figure 3. plenum Adapter

13.25"

18.5" (B-Cab.)

21.25" (C-Cab.)

Plenum

Connector

Connector

Tabs

Supply

Air Duct

Wood Floor

Duct Connector

Supply

Air Duct

Bend tabs tightly

against supply air duct

Figure 5. Duct connector Installed

Figure 4. perforated Flanges

Summary of Contents for B6BV Series

Page 23: ...23...