6

CONNECT THE AIR SUPPLY

(Refer to Figure 4)

• Snap the air hose onto the

quick connector.

• Check for air leakage. If

leakage is noted, cease using

the tool immediately and have it

checked by a qualified repair

personnel.

• Be sure the air pressure gauge

is operating properly and check it

at least twice a day.

TOOL TESTING

DANGER

OPERATORS AND OTHERS IN

WORK AREA MUST WEAR

SAFETY GOGGLES WITH SIDE

SHIELDS, WHICH CONFORM

TO ANSI Z87.1

SPECIFICATION.

WARNING

NEVER USE TOOL UNLESS

SAFETY IS OPERATING

PROPERLY.Before actually

beginning the nailing work, test

the tool by using the checklist

below. Conduct the test in the

following order.

If abnormal operation occurs,

stop using the tool and have it

repaired by a qualified repair

personnel immediately.

1. Disconnect air hose and

remove all nails from the tool. All

screws must be tightened. If any

screws are loose, tighten them.

The safety and trigger must

move smoothly.

2. Adjust the air pressure to 75

PSI and then connect the air

hose. The tool must not leak air.

3. Remove the finger from the

trigger ad press the safety

against the wood. The tool must

not operate.

4. Separate the safety from the

wood. Next, point the tool

downward, pull the trigger and

then wait in that position for 5

seconds or longer. The tool must

not operate.

5. Without touching the trigger,

depress the safety against the

work piece. Pull the trigger. The

tool must not operate.

Hold the trigger back while

separating the safety from the

wood. The tool will remain in

operated status (the driver blade

will remain at the bottom).

Remove the finger from the

trigger. Tool operation will end

(the driver blade will return to the

top).

6. If no abnormal operation is

observed, you may load nails in

the tool. Drive nails into the work

piece that is the same type to be

used in the actual

application.The tool must operate

properly.

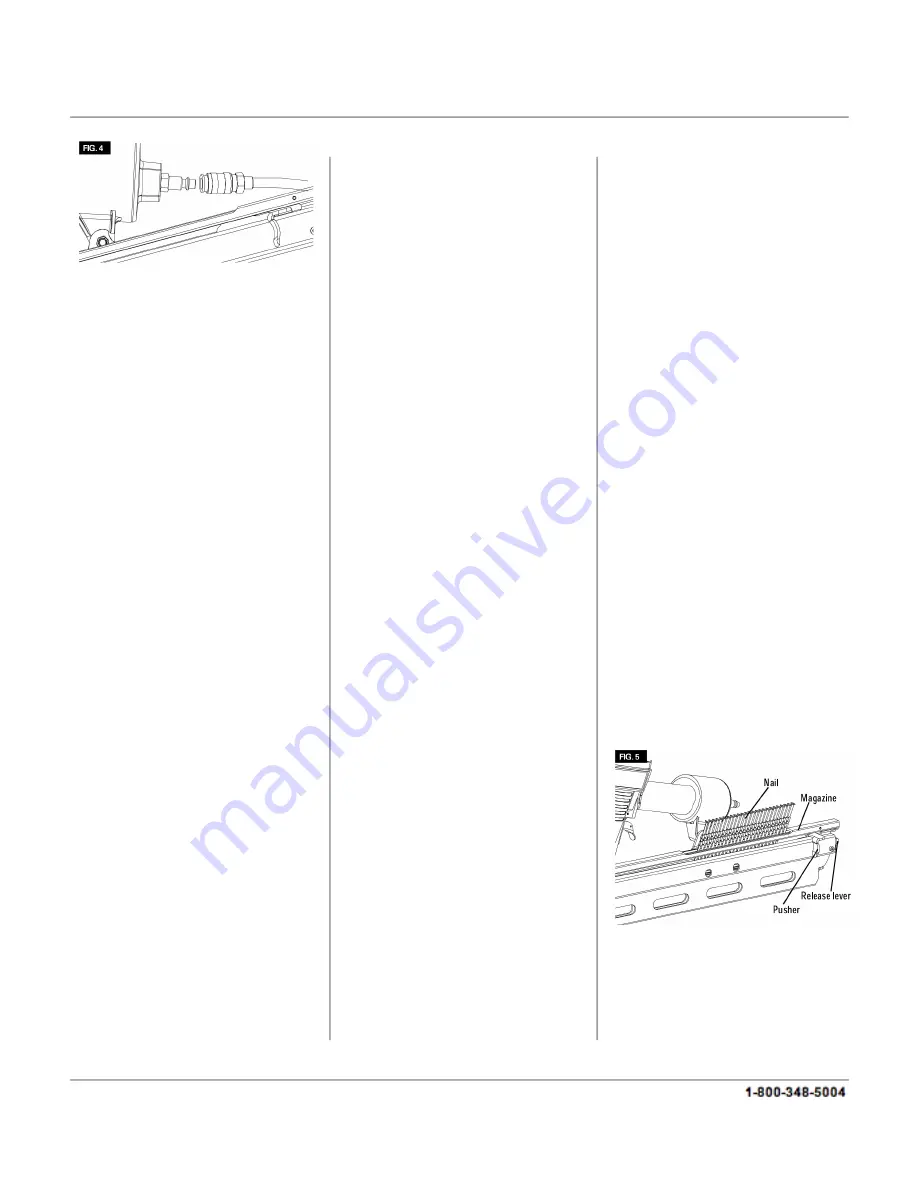

NAIL LOADING

(Refer to Figure 5)

WARNING

Always load nails into the tools

magazine before the air supply is

connected. Connecting the air

supply after loading nails

reduces the risk of

unintentionally driving a nail and

injuring yourself or someone

else.

WARNING

When loading the tool’s

magazine, check that the nail tips

contact the wear rail and slide

smoothly against the surface of

the magazine. If the nails are not

loaded properly, the tool will

misfire and nails can be

deflected, causing the tool to

react in an unexpected manner

and damage the tool.

1. Disconnect the air supply.

2. Hold the tool handgrip

securely and pull pusher back

until it locks in latched position

at rear of magazine.

3. Insert nail strip into

magazine, with nail points

angled forward and down.

4. Pull pusher back, press

release lever, and slide pusher

forward against nails.

5. Tool is now loaded and

ready for normal operation.

METHODS OF

OPERATION

This tool is equipped with a

safety and does not operate

unless the safety is depressed.

feedback@natitools.com