3

OPERATION

Start Up

1) Add 87 octane (or higher)

unleaded gasoline to the engine

gas tank and SAE 10W-30 oil to

the engine oil tank. A different

viscosity oil may be required if

the compressor is operated at

different ambient temperatures.

Please refer to the engine

manual for more details.

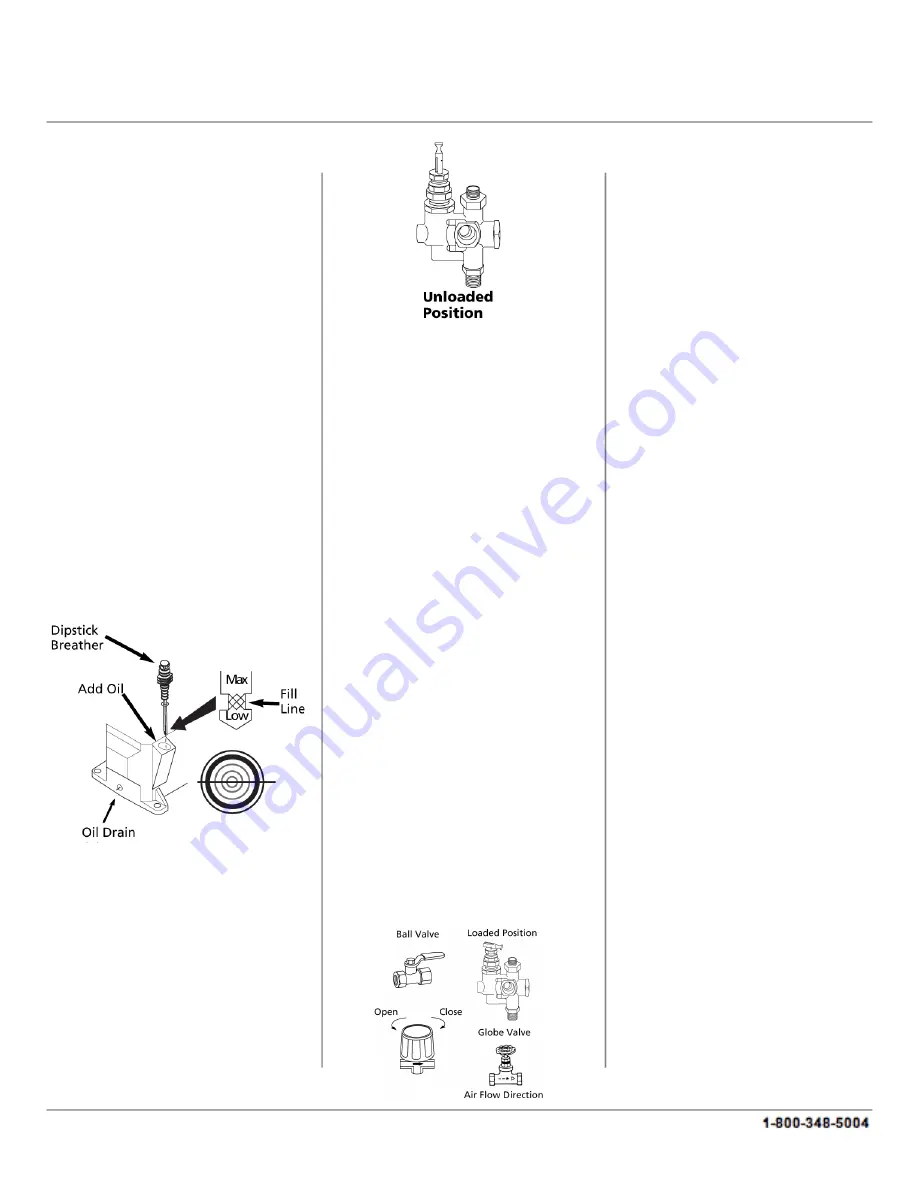

2) Remove the compressor

dipstick breather and fill the

pump to the proper oil level.

Use a single viscosity, ISO 100

(SAE 30) non-detergent

compressor oil. Do not use a

multi viscosity oil such as 10W-

30.

3) Turn the outlet valve or

regulator knob counterclockwise

to open the airflow.

4) Turn the manual unloader

lever to a vertical position in

order to allow the compressor

pump to run without

compressing air.

Starting A Gasoline Engine

1) Move the choke lever to the

CHOKE position and turn the

stop lever towards the ON

position.

2) Pull the start grip lightly until

resistance is felt, then pull on the

start grip briskly to start the

engine.

3) As the engine begins to warm

up, gradually move the choke

lever to the OPEN position.

4) Run the compressor at an

unloaded speed for

approximately 30 minutes in

order to break in the pump.

5) After approximately 30

minutes of run time, move the

unloader lever down to the

loaded position and turn the

regulator knob clockwise. The

compressor will begin to pump

air into the tank at this time.

When the maximum tank

pressure is achieved, the

compressor automatically

unloads, which brings the

engine to idle. The engine

remains at the idle state until the

pressure in the tank falls to a

preset level. The engine will then

accelerate and the compressor

will pump additional air into the

tank.

MAINTENANCE

WARNING: Release all

pressure from the system

before attempting to perform

any maintenance, relocate,

service or install the unit.

Check the air filter, oil level and

gasoline level before each use in

order to maintain efficient

operation of the unit.

The ASME safety valve should

be checked before each use. Pull

the ring on the safety valve and

allow the ring to snap back into

its normal position. This valve

automatically releases air if the

tank pressure exceeds a preset

maximum. If air leaks after the

ring has been released, or if the

valve is stuck and cannot be

actuated by the ring, the ASME

safety valve must be replaced.

Do not attempt to tamper with

the ASME safety valve.

With the engine OFF, clean any

debris from the engine, flywheel,

tank, air lines and pump cooling

fins.

Never attempt to repair or

feedback@natitools.com