20

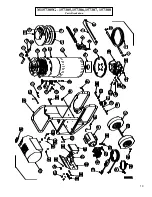

ITEM PART # DESCRIPTION

QTY

MODEL

ITEM PART # DESCRIPTION

QTY

MODEL

1

38525

50’ PW Hose Assy

1

ALL

35

38379 Swivel Fitting, 6MP-8FPS

1

ALL

2

777914 Quick Couple, 3/8” FPT

1

ALL

36

5027

Elbow, 8MP-FP

1

ALL

3

777915 Quick Couple Nipple, 3/8” FPT

1

ALL

37

38509 Threaded Gun Hook

2

ALL

6

777904 Quick Coupler, 1/4” FPT

1

ALL

38

38510 Threaded Hose Hook

3

ALL

7

779166

Lance

Assembly

1 ALL

39

777111 Grommet

1 ALL

8

313107 Quick Couple, 3/8” FPT

1

ALL

40 778092 Hot Water Frame

1

ALL

9

779168 Gun Trigger Assembly

1

ALL

41

32308 Fuel Filter, Water Separator

1

ALL

10

22622

Gun Grip

1

ALL

42

30388 Pneumatic Wheel/Tire

2

ALL

11

38398

Insulation Cap Assembly

1

ALL

43 305408 Axle

1

ALL

12

36302

Fiberglass Rope

49”

ALL

44 305200 Wheel Retainer

2

ALL

13

35331

Heat Exchanger Lid

1

ALL

777165 Braided Chemical Hose, 1/4”

36” 157305, 157306

14 305410 ~Caution Hot~ Decal

1

ALL

45

777165 Braided Chemical Hose, 1/4”

36” 157307, 157308

15 777913 Quick Couple Nipple, 3/8”

1

ALL

46

2212

Chemical

Strainer

1

ALL

16

30048

Reducer, 8MP – 6FP

1

ALL

47 778236 Thread-on Coupler, 22mm

1

157305, 157306

17 305208 Tee, 8FP

1

ALL

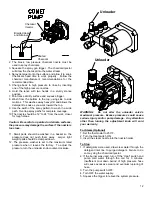

778153 Comet GXD 1617-E

1

157305

18 778179 Kink Guard

1

ALL

778162 Comet GXD 2527G-E

1

157306

19 779228 Coil Assembly

1

ALL

778154 Cat 2DX

1

157307

20 33387 Insulation

Can

1

ALL

48

38518 Cat

3DX

1

157308

21 779232 Fire Chamber

1

ALL

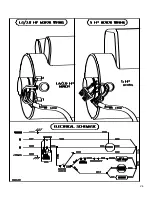

777616 Leeson, 1.5 HP Motor

1

157305

37530

Vented Wrap

1

157305, 157306

778670 Leeson 5 HP Motor

1

157306, 157308

22

36180

Vented Wrap, Stainless

1

157307, 157308

49

777617 Leeson, 2 HP Motor

1

157307

23

38120

Insulation Gasket

1

ALL

50 779303 Control Box Cover

1

ALL

24 778111 Heat Exch. Mount Weld.

1

ALL

51

31985 Grommet

1

ALL

777166 Burner, 120V

1

157305, 157307

52 779301 Control Panel Weldment

1

ALL

25

778189 Burner, 230V

1

157306, 157308

53

35198 Grommet, 7/16” ID

6

ALL

26 305267 Strain Relief Nut

2

ALL

778197 Nozzle 5-pack, #2.0

1

157305, 157307

27

22502

Strain Relief

1

157306, 157308

54

38531 Nozzle 5-pack, #3.0

1

157306, 157308

28 777340 Hose Barb, 1/4” MPT x 1/4”

4

ALL

55

778198 Steam Nozzle, 15 Deg

1

ALL

29 777834 Hose Clamp, 1/4”

4

ALL

778151 DP Contactor, 120V/25A

1

157305, 157307

30A 777345 Fuel Line, 1/4” Burner-Tank

25”

ALL

56

778152 DP Contactor, 230V/30A

1

157306, 157308

30B 777345 Fuel Line, 1/4” Filter -Burner 10”

ALL

57

30754

Leather

Washer

4

ALL

30C 777345 Fuel Line, 1/4” Tank to Filter

25”

ALL

58 3054007 Fuel Tank

1

ALL

35104

Pop Off Valve, 3/8”

1

157305, 157307

59 305206 Printed Fuel Cap

1

ALL

31

22392

Pop Off Valve, 3/8”

1

157306, 157308

60 777410 Elbow, 3/8” NPT

1

157305,157306

778195 3000PSI RXS Hose, 3/8x18”

18” 157305, 157306

61 305266 Strain Relief, 1/2” NPT

1

157306,157308

32

778193 3000PSI RXS Hose, 3/8x26”

26” 157307, 157308

778194 Motor Power Cord 14/3

1

157305

33

777347 Tee,

6MP-6FP-6FP

1

ALL

62

778191 Motor Power Cord 12/3

1

157306, 157307,

157308

34

37537 Flow Switch

1

ALL

778141 GFCI Cord, 120V/20A, 36 ft

1

157305, 157307

63

778142 GFCI Cord, 240V/30A, 36 ft

1

157306, 157308

M157305G - 157305,157306,157307, 157308

Parts List

Summary of Contents for 157305

Page 19: ...19 M157305G 157305 157306 157307 157308 Parts Breakdown ...

Page 22: ...22 ...

Page 23: ...23 ...

Page 24: ...24 ...