Operation Instructions

8

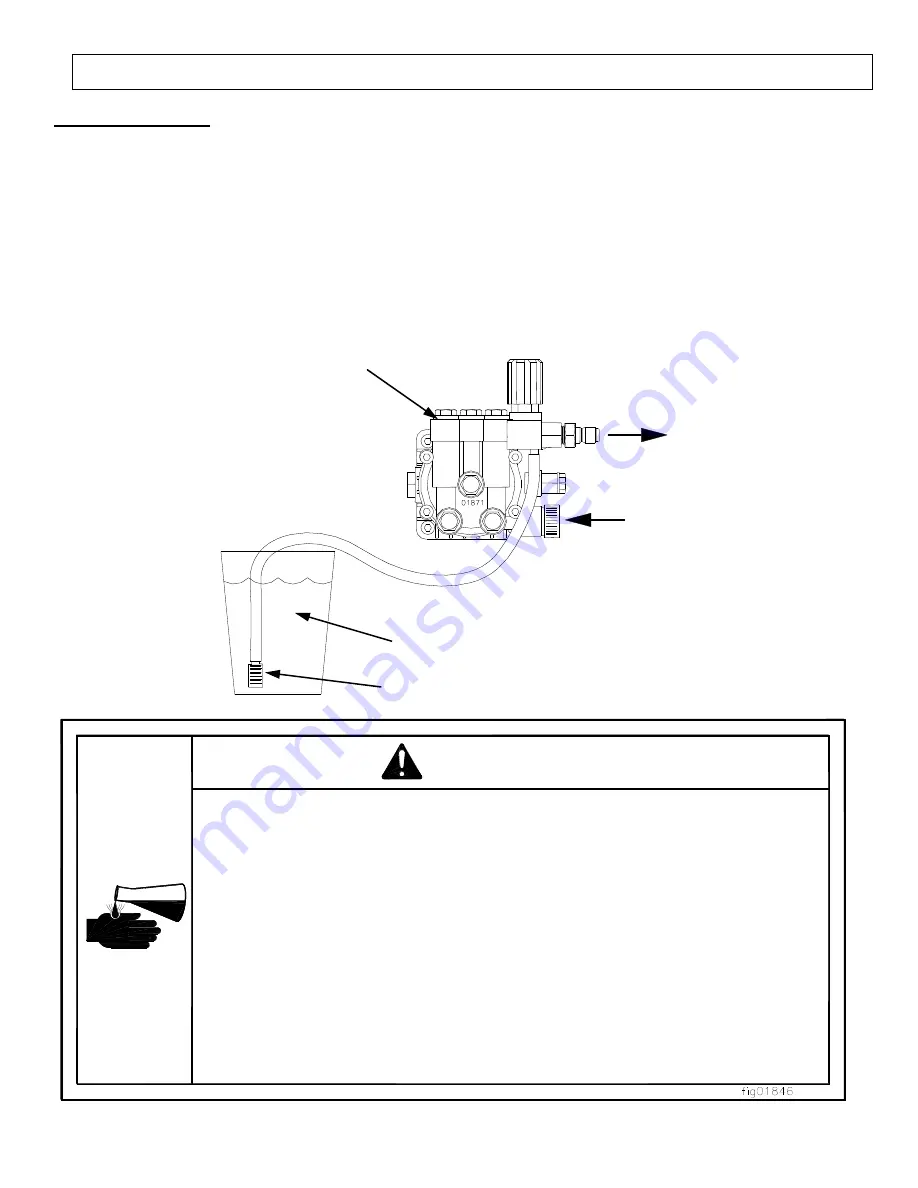

Applying Chemicals

1.)

Install the black nozzle when applying chemicals onto the cleaning surface.

2.)

Start the pressure washer according to the start-up instructions.

3.)

Submerge the chemical hose in cleaning solution. (See Pump Component Identification section for chemical

injector location.)

4.)

Squeeze the spray gun trigger. The chemical injector will draw the chemical into the water stream.

5.)

Apply chemicals evenly onto the cleaning surface. Allow the chemicals to react with the dirt, then clean at

high pressure with high pressure (green or yellow) nozzle.

6.)

Never use more chemical than is necessary to clean the surface.

7.)

To clean the chemical injector, draw water through the strainer until all the chemical is purged from the

system.

Risk of exposure to dangerous chemicals.

Serious injury or death can result if chemical manufacturer instructions are not

followed.

-Wear protective gloves when handling and cleaning with chemicals.

-Understand all safety hazards and first aid for all chemicals being used.

-When cleaning filters, check if chemicals have been used and take any

precautions that are recommended by the chemical manufacturer.

-Different chemicals may interact dangerously with each other, always follow

chemical manufacturer directions before switching chemicals.

-Calculate the correct amount of chemical to mix, dispose of excess chemical

per the manufacturer instructions.

-Never spray flammable liquids.

WARNING

strainer

diluted

chemica

l

pump inlet

pump outlet

outletoutl

et

pump

Summary of Contents for A1573001

Page 2: ...Hazard Signal Word Definitions 2...

Page 6: ...Pump Component Identification 6 A157306 A1573001 A1573021 A1573011 A1575581...

Page 14: ...Parts Explosion MA1573001 Rev A 1 14...

Page 16: ...Pump Exploded Views 16 A1573001...

Page 17: ...Pump Exploded Views 17...

Page 18: ...Pump Exploded Views 18 A1573011...

Page 19: ...Pump Exploded Views 19 A1573021...

Page 20: ...Pump Exploded Views 20 A157306...

Page 21: ...Pump Exploded Views 21...

Page 22: ...Pump Exploded Views 22 A1575581...

Page 23: ...23 This page has intentionally been left blank...