Operation – Using the Sprayer

25

Step One: Assess wind conditions and clear work area.

Before you decide to spray, you must determine whether wind conditions are suitable. You must

also restrict access to the work area to ensure the safety of bystanders.

WARNING

Do not spray if wind speeds are greater than 4 MPH or if there are

bystanders in the intended spray area.

1. Assess wind speed

Assess weather conditions to ensure that it is not too windy to spray.

DO NOT SPRAY if wind speeds are greater than 4 MPH.

Visible indication of wind speed

:

If leaves are in constant motion or there is any branch movement, DO NOT

spray because the wind is too strong.

2. Clear work area

Clear the work area of all bystanders and pets.

Restrict access by the public for the period recommended on chemical label.

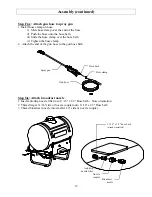

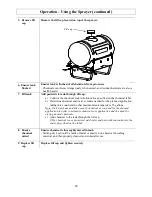

Step Two: Fill the sprayer.

WARNING

ALWAYS wear personal protective equipment as directed on the

chemical label when handling pesticides.

Long pants and sleeves, chemical resistant gloves, and eye protection are

strongly recommended. Additional protective gear may be required

depending on the particular pesticide.

Fill the sprayer using the following steps:

1. Review safety

information

Review the "Operation – Important Safety Information"

related to General

Chemical Safety and Chemical Accident Procedures provided in this manual.

2. Choose safe

mixing/

loading area

Choose a safe pesticide mixing and loading area.

- Choose an outdoor, well-ventilated area away from unprotected people, animals,

food, and other items that might become contaminated.

3. Wear personal

protective

equipment

Wear personal protective equipment as directed on the chemical label.

- Note that additional equipment may be specified for mixing and loading activities.

4. Turn off

sprayer and

vehicle

Turn OFF power to the sprayer before filling.

- The vehicle should also be off, with brake set or wheels blocked to prevent

unintended movement.