FIGURE 8 - POSSIBLE PROBLEM

PROBLEM

POSSIBLE CAUSES

Gas Smell

Possible gas loss.

Check external pipes and connections.

Smell of non-burner gas

Check that the combustion is regular.

Check that the consumption of gas is not

excessive.

Check that there are not obstructions in the

encircled of the warm smokes.

Check that aspinant and area ventilation are

operating property.

‘

Explosions ' in the burners

Check the pressure of the gas.

The main burner is not ignited

Check that there is no leak in the gas supply or

any problem with the nozzle.

The components of the burner are well

positioned.

2.0 SAFETY VALVE...........................................

The valve that regulates the influx of the gas is provided safety thermal that it

assures the block of influx of the gas in case of accidental turning off of the

flame.

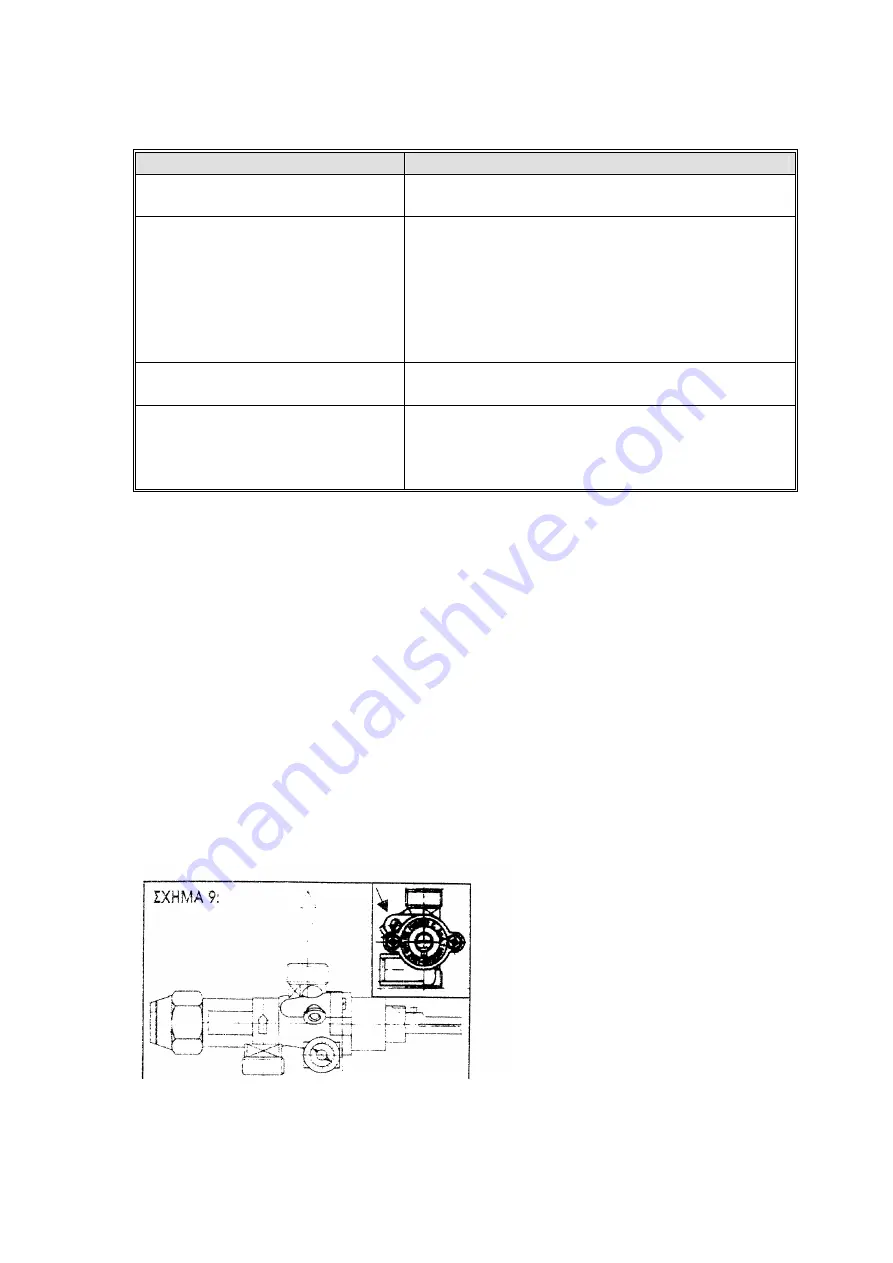

2.0 REGULATION OF THE MINIMUM BURNING ....................................… ....

The nozzle of the valve (bypass) has a hole of 0,50 mm and for the gas G30

Must be fully screwed.

In case of regulation for other gases G20 the bypass must be unscrewed (by

Turning the screw anti-clockwise until a clear and regular flame appears).

To regulate the bypass, turn on the burner to the minimum setting, remove

The handle grip of the valve and regulate the screw marked with arrow in the

Adjacent figure, until a clear and regular flame appears.

The screw of the regulation must be fully screwed passing from the natural

To G.P.L. and open in the inverse case.