3 of 4

OPERATING INSTRUCTION

1.Make sure the tool is disconnected from the air hose.

2.Wear appropriate eye, ear and other safety equipment.

3.Place 5-7 drops of lubrication into the air inlet before use and clean the pneumatic tool

after each use.

4.Check for smooth and proper operation of the nosepiece. Do not use the tool if the nose

assembly is not functioning or is restrained.

5.Keep tool pointed away from yourself and others.

6.Connect air hose using only clean, dry, regulated compressed air at 70-100 PSI.

7.Check for audible leaks around valves and gaskets. Never use a tool that leaks or has

damaged parts.

8.Keep tool pointed in a safe direction when loading nails. Hold the nail in the same manner

as if you were using a common hammer. With the other hand place the tool in a straight line

with the direction in which you intend to drive the nail.

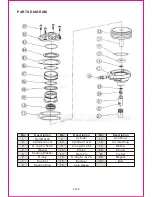

9.Place the fix set (#21) around the nail head, and gently push the tool until the nail head

comes into contact with the ram pin (#13) and is steady.

10.Remove the hand that is holding the nail, and continue pushing the tool to drive the

fastener into place.

TROUBLE SHOOTING

INSPECTION, MAINTENANCE AND CLEANING

·

Always disconnect the pneumatic tool from its compressed air supply before performing

any inspection, maintenance, adjustments or cleaning.

·

Place 5-7 drops of pneumatic tool oil into the air inlet before each work day or after 2 hours

of continuous use.

·

Clean daily with a clean cloth to remove all dirt, oil and grease from the pneumatic tool. If

necessary, you may use a mild detergent. Do not use solvents, as damage to the pneumatic

tool may occur. Do not immerse the pneumatic tool in any liquids.

Symptom

Air Leaking

Attack strength not enough

No nail fires when connected

air pressure

Problems

Solution

Worn O-ring or loose screw

Air pressure is not in specified range.

The O-ring beside slip set is worn.

Insufficient air supply.

Worn O-ring.

Replace O-ring or tighten screw.

Adjust air pressure to the specified

range.

Replace O-ring.

Adjust air pressure.

Check and replace O-ring.

Summary of Contents for 112020

Page 1: ......