Thank you very much for choosing a NORTHERN TOOL + EQUIPMENT CO., INC.,

Product! For future reference, please complete the owner’s record below:

Model: _______________ Purchase Date: _______________

Save the receipt, warranty and these instructions. It is important that you read the entire

manual to become familiar with this product before you begin using it.

This machine is designed for certain applications only. Northern Tool + Equipment

strongly recommends this machine is not modified and/or used for any application other

than that for which it was designed. If you have any questions relative to a particular

application, DO NOT use the machine until you have first contacted Northern Tool +

Equipment to determine if it can or should be performed on the product.

For technical questions and replacement parts, please call 1-800-222-5381.

DESCRIPTION & INTENDED USE

The PTO-DRIVEN 6" wood chipper features an advanced design with a compact structure,

superior technology and substantial attack strength. This model is safe and easy to

operate.

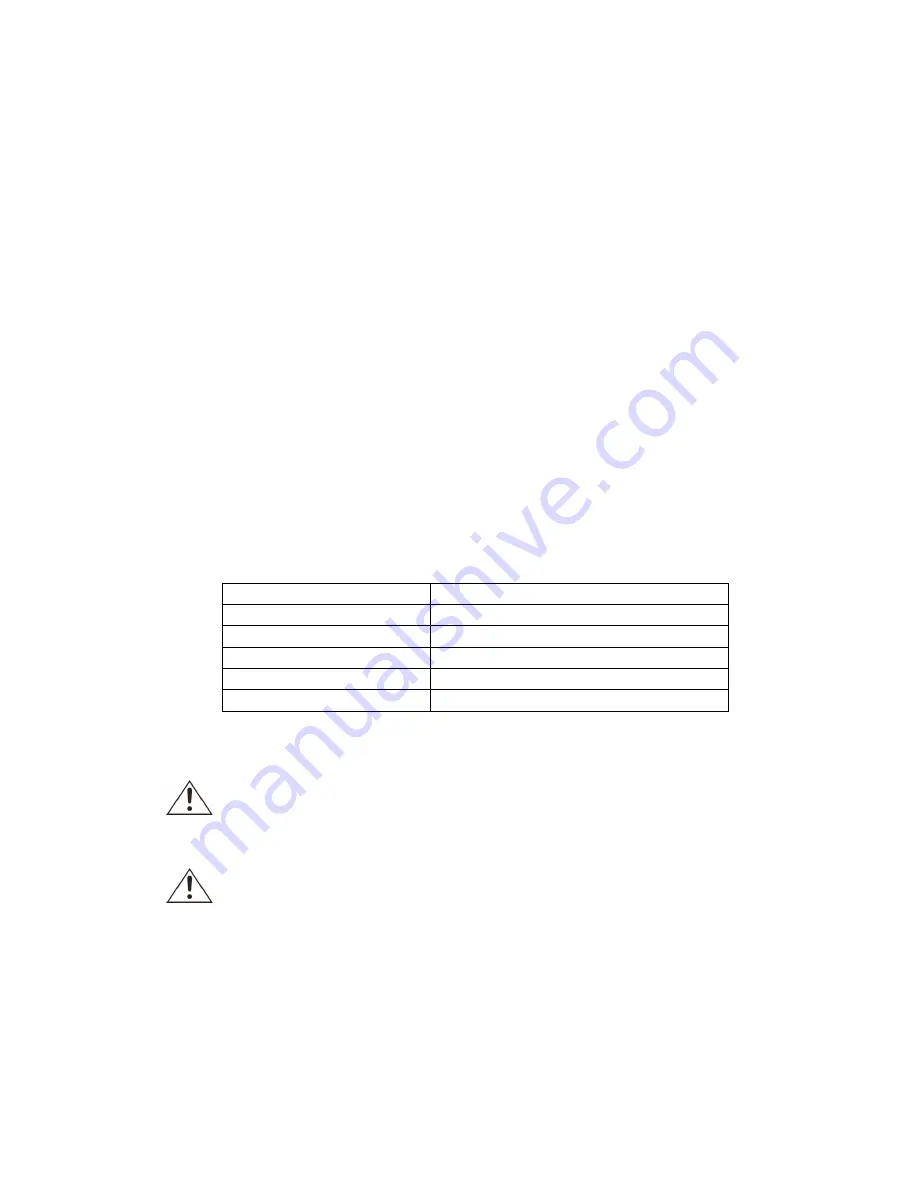

Technical Specifications

Item

Description

PTO

540 RPM

Flywheel Dia.

2 Feet (605mm)

Flywheel RPM

1220

Max Chipping Dia.

6"

Net Weight

772 Lbs. (350 kg)

GENERAL SAFETY RULES

WARNING:

Read and understand all instructions.

Failure to follow all

instructions listed below may result in electric shock, fire and/or serious injury.

WARNING:

The warnings, cautions, and instructions discussed in this

instruction manual cannot cover all possible conditions or situations that could

occur. It must be understood by the operator that common sense and caution are

factors which cannot be built into this product, but must be supplied by the

operator.

SAVE THESE INSTRUCTIONS

Summary of Contents for 180100

Page 10: ...PARTS LIST...