Page 5 of 9

Personal Safety

WARNING:

Personal injury and/or equipment damage may result if proper safety

precautions are not observed. Even low pressure is very dangerous and cause injury or death.

1. Ensure that reel is properly installed before connecting input and output hoses.

2. Bleed fluid/gas pressure from system before servicing reel.

3. Before connecting reel to supply line, ensure that pressure does not exceed maximum working

pressure rating of reel (300 PSI).

4. If a leak occurs in the hose or reel, remove system pressure immediately. Do not use until the hose

has been properly repaired.

5. If reel ceases to unwind or rewind, remove system pressure immediately. Do not pull or jerk on

hose.

Installation Instructions

1. Prior to mounting the hose reel, ensure that the supply line pressure does not exceed the maximum

working pressure of the hose reel.

2. Unpack and inspect the reel for damage.

3. Turn reel by hand to check for smooth operation. Check for complete components.

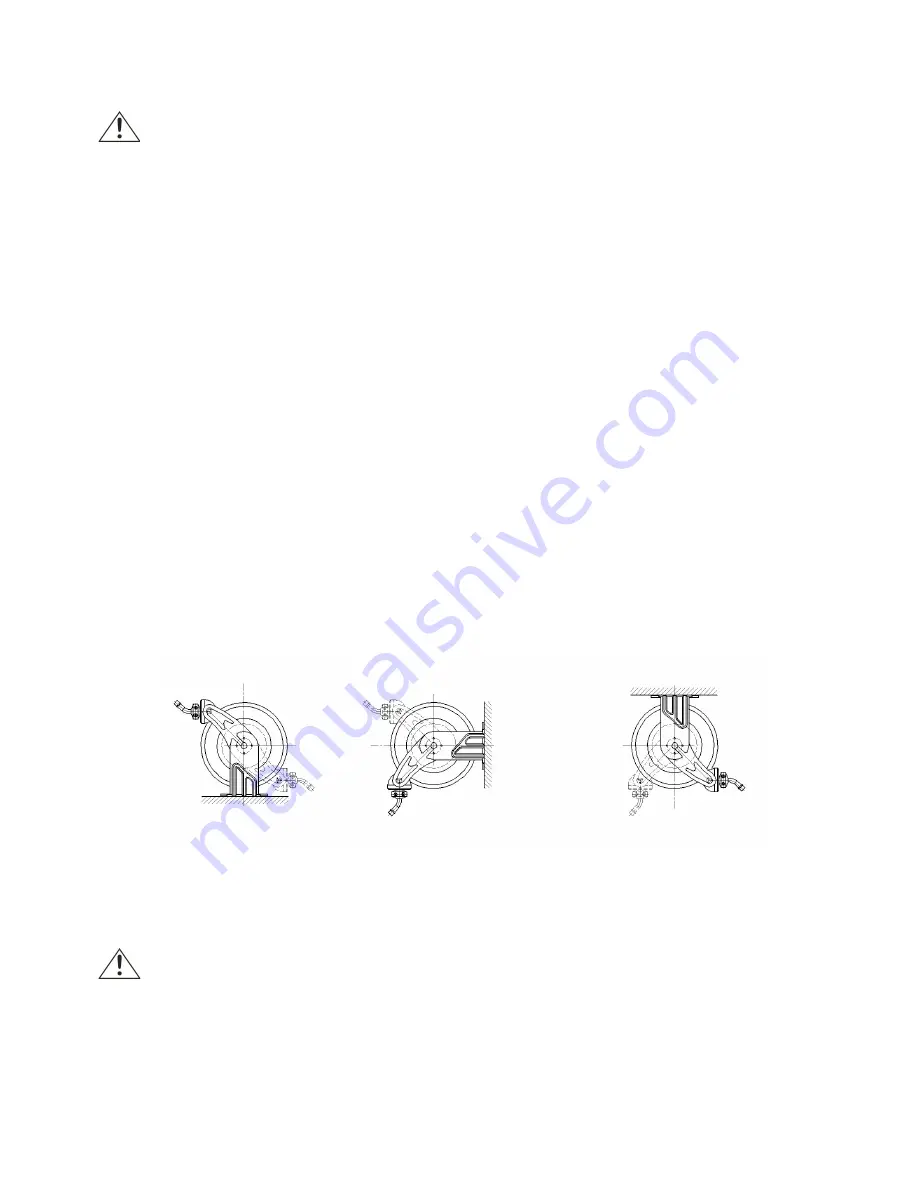

4. Position the reel on the floor, wall or ceiling. Secure into place using four mounting bolts (not

included) and installation template.

5. Depending on where the reel is placed, it may be necessary to adjust the hose bumper and guide

arm to use the hose properly. See the instructions below to adjust the hose bumper and the guide

arm.

ADJUSTING YOUR HOSE REEL

1. Adjusting spring tension

WARNING: Use extreme caution; reel under tension. Avoid releasing latch

mechanism.

If necessary, adjust spring tension on reel by adding or removing the hose from the spool, one wrap at

a time, until desired tension is obtained. Add hose to increase tension. Remove hose to decrease

tension.

Pull out the hose until the latch pawl is engaged. Loosen the hose bumper, then add wraps and

decrease the wraps until desired tension is achieved.