3 of 4

MAINTENANCE

Your Air Ratchet Wrench is best operated with an airline oiler. If you are using this tool

without an airline oiler, follow steps below:

1.Disconnect the Air Ratchet from the air hose.

2.Apply a few drops of Pneumatic Tool Oil through the air line before each use, or every

hour if used continuously.

3.Apply a few drops of oil to the Roll Pin. Squeeze the trigger a few times to lubricate.

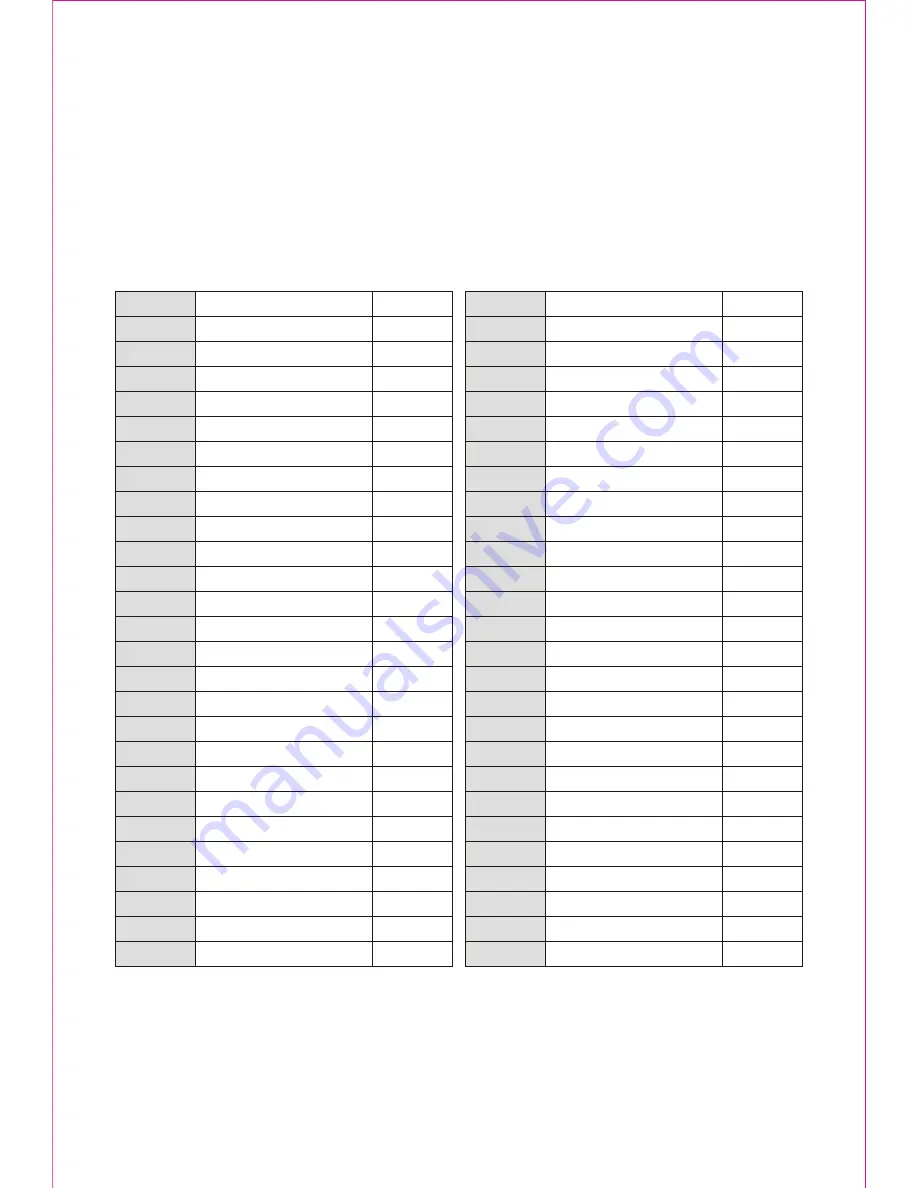

Diagram

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

1

1

3

3

1

1

1

1

1

1

1

1

1

2

2

1

2

2

1

1

1

2

1

1

2

Part No.

Description

Qty.

Description

Part No.

Qty.

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

9

1

10

1

11

1

12

1

13

1

14

1

15

1

16

1

17

1

18

1

19

1

20

1

21

1

22

2

24

25

26

1

1

1

23

4

Housing

Valve stem

Throttle level

O-ring

Trigger pin

Air inlet

Spring

Lock pin

O-ring

Air regulator

O-ring

Inlet adaptor

Valve spring

Throttle valve

Valve seat

Plastic grip

O-ring

Exhaust deflector

Ball bearing

Rear end plate

Dowel pin

Rotor blade

Rotor

Cylinder

Front end plate

Ball bearing

Washer

Thread ring gear

Planet gear

Gear shaft

Gear plate

Clamp nut

Busing

Needle bear

Crank shaft

Ratchet housing

Drive busing

Ratchet yoke

Reverse button

Spring

Lock pin

Washer

Anvil

Pin

Ratchet pawl

Thrust washer

Retainer ring

Spring

Steel ball

Spring

Steel ball

44

45

46

47

48

49

50

51

Summary of Contents for 1/2" AirRatchet Wrench

Page 5: ...4 of 4 ...