5

pressure above that required at the air service

connection. The air inlet filter openings must be

kept clear of obstructions, which could reduce air

delivery of the compressor.

Installation and Location

Locate the compressor in a clean, dry and well

ventilated area. The compressor should be located

12 to 18 inches from walls or any other obstruction

which would interfere with airflow. Compressor

should be located in a temperature controlled area

between 32° and 95° fahrenheit. Place the

compressor on a firm, level surface. The

compressor is designed with heat dissipation fins

which allow for proper cooling. Keep the fins (and

all other parts which collect dust or dirt) clean. A

clean compressor runs cooler and provides longer

service. Do not place rags, containers or other

material on top of the compressor.

Connecting to Power Source

This air compressor is designed to operate on a

properly grounded 120 volt, 60Hz, single phase,

alternating current (ac) power source with a fused

20 amp time delayed fuse or circuit breaker. It is

recommended that a qualified electrician verify the

ACTUAL VOLTAGE at the receptacle into which the

unit will be plugged and confirm that the receptacle

is properly fused and grounded. The use of the

proper circuit size can eliminate nuisance circuit

breaker tripping while operating your air

compressor.

Extension Cords

For optimum Air Compressor performance an

extension cord should not be used unless

absolutely necessary. If necessary, care must be

taken in selecting an extension cord appropriate for

use with your specific Air Compressor. Select a

properly grounded extension cord which will mate

directly with the power source receptacle and the

Air Compressor power cord without the use of

adapters. Make certain that the extension cord is

properly wired and in good electrical condition.

Maximum length of extension cord should be 50

feet. Minimum wire size of extension cord should be

12 gauge.

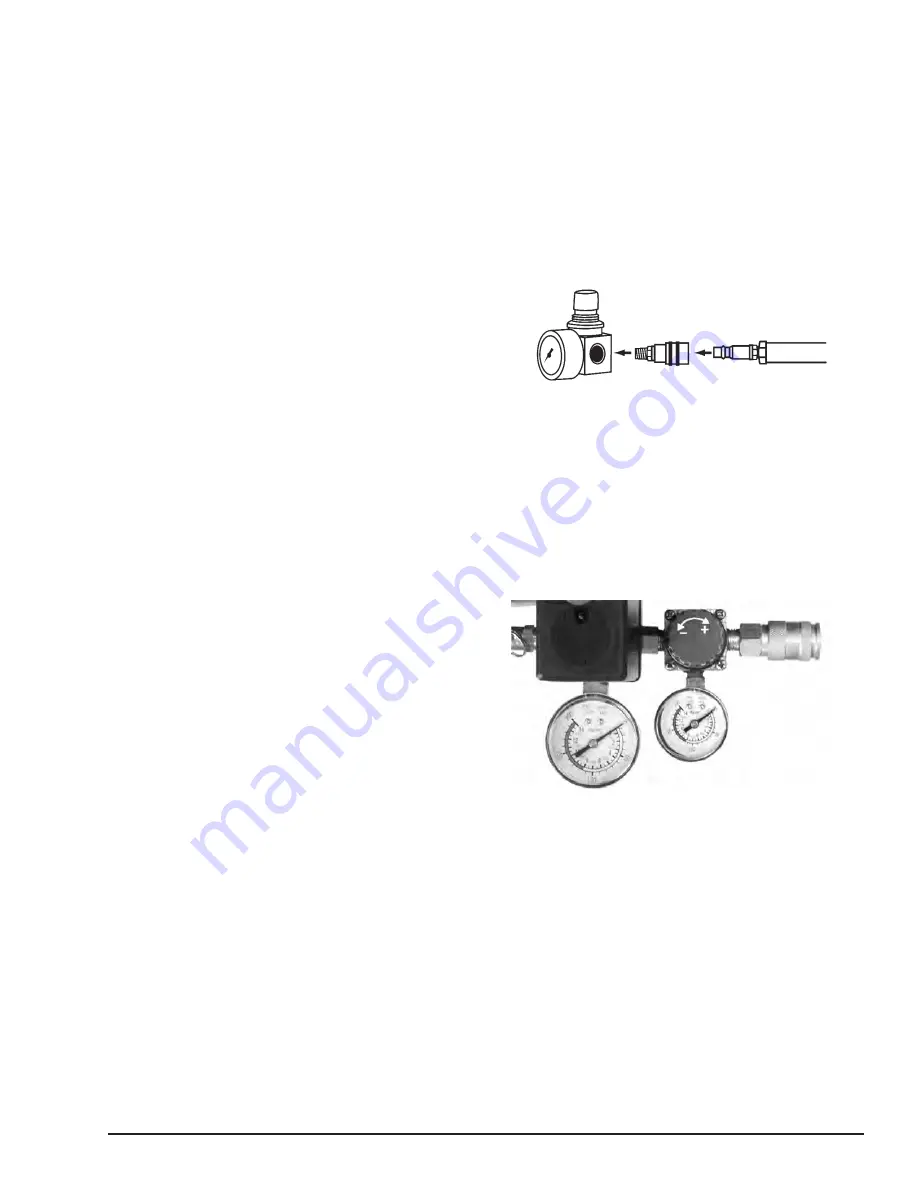

Attaching an Air Hose

Your Air Compressor is supplied with a 1/4" Quick

Disconnect Air Chuck. Once you have correctly

installed the Air Chuck (See Installing the Air Chuck

on p.4) your compressor will be ready to accept air

hoses equipped with 1/4" male air couplers.

Note:

Use only air hoses rated for use with 115psi

air pressure or higher.

To install an air hose, equipped with a 1/4" male

coupler:

1. Pull back on Air Chuck outer sleeve to allow

coupler to be fully inserted into Air Chuck.

2. Insert coupler into Air Chuck.

3. Release outer sleeve of Air Chuck.

4. Verify that air hose is securely connected to Air

Chuck by pulling lightly on air hose.

(See Figure 5)

Adjusting the Air Pressure

Your Air Compressor is supplied with an Air

Pressure Regulator. This Regulator adjusts the air

pressure.

To increase air pressure, turn Air Regulator

clockwise.

To decrease air pressure, turn Air Regulator

counterclockwise.

(See Figure 6)

Cold Weather Starting

Temperatures below freezing (32°F) cause the

metal parts of your Air Compressor to contract and

that makes starting more difficult. To assist the Air

Compressor in starting in cold weather, follow

these tips:

1. Try to keep Air Compressor stored in

temperatures above 32° fahrenheit.

2. Open the Air Tank Drain Valve and release all

air pressure from the Air Tank before attempting

to start in cold weather. (After air is released

from Air Tank, close Drain Valve.)

3. Plug Air Compressor directly into a 120 volt

electrical outlet. Do not use an extension cord

when starting your Air Compressor in cold

weather.

Figure 5.

Attaching an Air Hose

Figure 6.

Adjusting the Air Pressure

Summary of Contents for 123006

Page 1: ...2 HP 4 GALLON AIR COMPRESSOR OPERATING MANUAL Item 123006...

Page 10: ...9...

Page 11: ......