OM843NW3 5/21

23

SP-14. HEAT EXCHANGER

1. Clean the heat exchanger core every 24 months, or

after 2500 hours of operation, or as needed.

2. Drain expansion tank and heat exchanger.

3. Remove heat exchanger end covers and remove

core.

4. Clean the inside of exchanger core tubes using

a metal rod. Flush, inspect and clean again if

necessary.

5. Reassemble. Fill the cooling system, start the engine

and check for leaks.

SP-15. RAW WATER PUMP

1. Change the seawater pump impeller every 500 hours,

or as needed.

2. Remove the pump end cover. Pry out the impeller

using needle-nose pliers or two screwdrivers.

Be sure you remove all pieces of failed impeller.

NOTE: Place some kind of protection under the

screwdrivers in order not to damage the pump

housing.

3. Clean the inside of the housing.

4. Press in the new impeller and place the sealing

washers in the outer end of the impeller center if this

has not already been done.

5. Replace the cover using a new gasket.

NOTE: Make sure that there is always an extra

impeller and cover gasket in reserve on board.

SP-16. EXHAUST ELBOW

1. Visually inspect the exhaust elbow every 500 hours

of operation, or sooner if needed. If any rust or other

damage is noted, replace the elbow.

GENERATOR ENDS

The maintenance and operation recommendations for

the generator end are can be found in Owner’s Manual

OPX300K-2, included with your manual kit. Contact

your Authorized Northern Lights dealer or factory

representative for additional copies.

ELECTRICAL SYSTEM - GENERAL

CAUTION:

Excessive non-linear loads can

lead to regulator and/or generator end failures

and should be no greater than 20% of overall

load. Failures caused by excessive non-linear

loads are not warrantable.

1. Never switch battery switch off or break the circuit

between the alternator and batteries while the engine

is running. Regulator damage can result.

2. Do NOT reverse the polarity of battery cables when

installing the battery.

3. When welding near the unit, disconnect the AC and

DC voltage regulator and battery. Isolate the leads.

4. Disconnect the battery cables when servicing the D.C.

alternator.

5. Never test with a screwdriver, etc., against any

terminal to see if it emits sparks.

7. A D.C. circuit breaker protects your control panel

and wiring harness. It is located in the side of the

generator junction box.

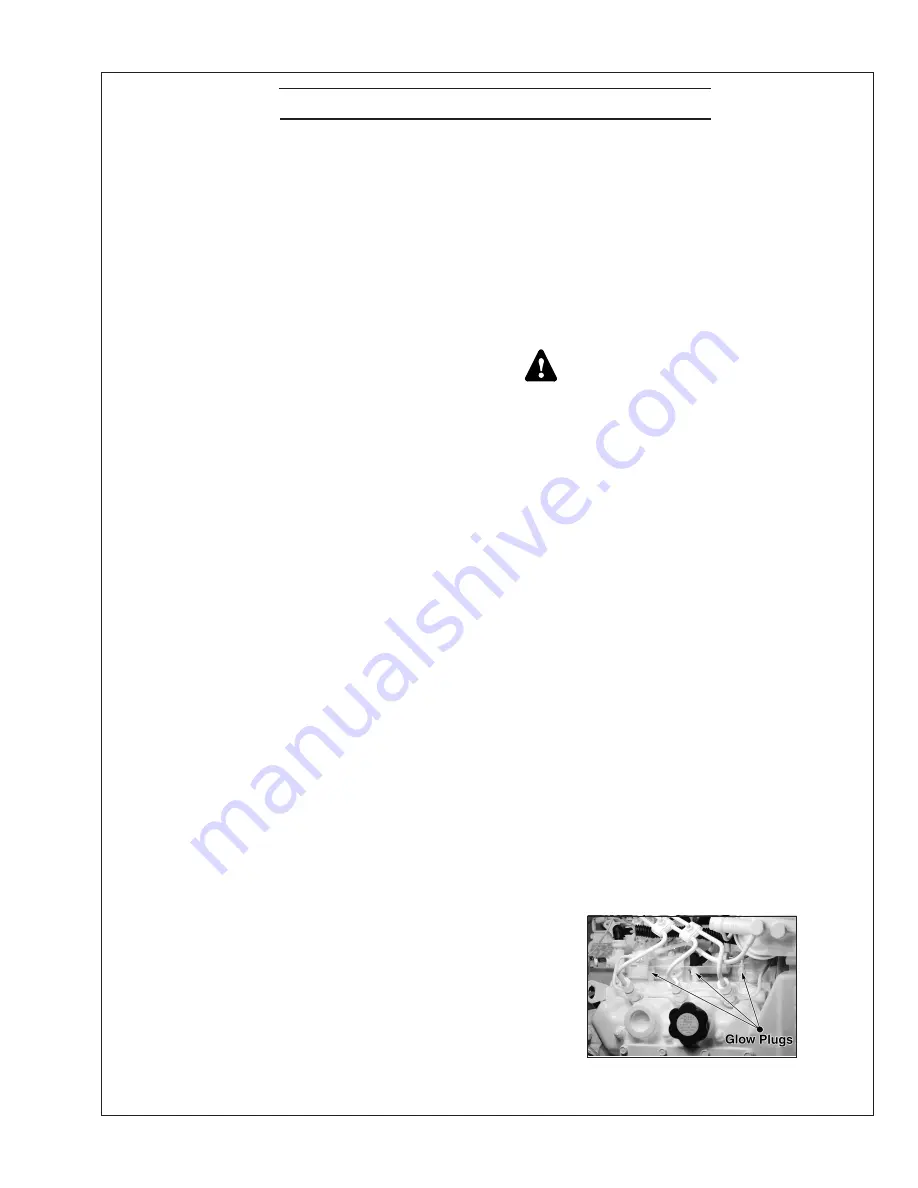

GLOW PLUGS

1. Each cylinder is supplied with a glow plug which

serves to heat the combustion chamber for starting.

2. To check the glow plugs, measure the resistance

between terminal and engine block, using a high

quality meter. Resistance should be under 1 ohm.

3. Check all glow plugs and replace any that are faulty.

Servicing

Figure 18:

Glow plugs.

Updated 5-13-21

Summary of Contents for Lugger M843NW3

Page 55: ......