OM844W3 11/13

24

Servicing

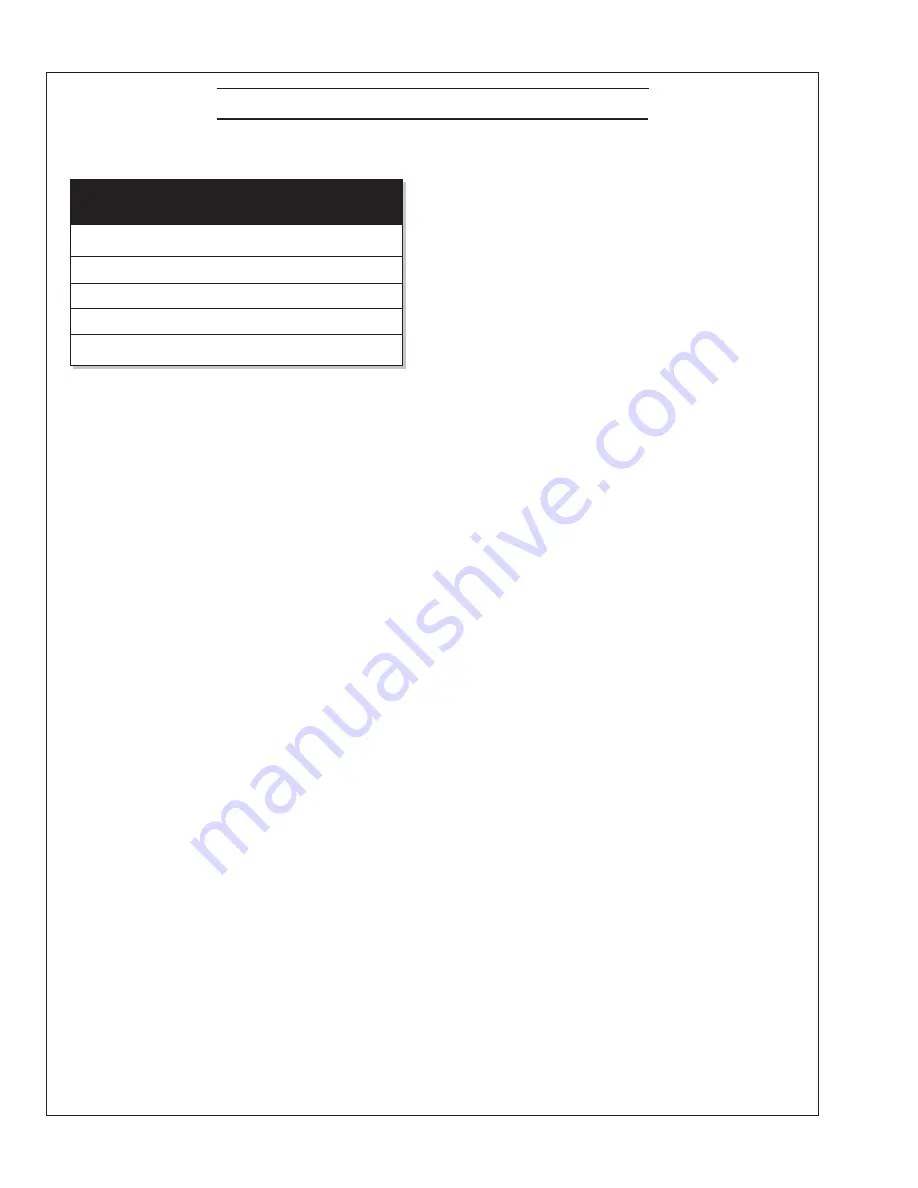

2. Here are acceptable water quality specifications:

3. If chlorides, sulfates or total dissolved solids are

higher than the above given specification, the water

must be distilled, demineralized, or

deionized before it is used in a cooling system.

4. If total hardness is higher than 170 ppm and all other

parameters are within the given

specifications, the water must be softened before it is

used to make coolant solution.

SP13. CHECK THE COOLANT LEVEL

1. Check the coolant level each day before starting the

engine. Check the water level by removing the

pressure cap from the expansion tank.

In order to give the cooling water an opportunity to

expand, the level should be about 1 in. (2.5 cm) below

the filler cap sealing surface when the engine is cold.

2. The pressure valve in the filler cap releases when the

pressure is approximately 7 PSI (0.5 bar). Use a cap

pressure tester to check cap if you suspect it is faulty.

SP14. COOLING SYSTEM FLUSHING

1. Flush the cooling system every 2500 hours.

2. Marine sets:

a. Remove expansion tank cap and drain engine

block.

b. Open block drain cock. Remove hose from

bottom of heat exchanger tank.

c. Pour clean water into expansion tank until water

coming from drains is free of discoloration and

sediment. Let water drain completely. Close

drains and refill with recommended mixture.

3. Coolant Specifications:

Use 50% distilled water / 50% ethylene glycol

antifreeze mix. Antifreeze mixture is recommended

as a good year-round coolant.

4. Check hoses and connections and repair any leak-

age.

SP15. HEAT EXCHANGER

1. Clean the heat exchanger core after 2500 hours of

operation.

2. Drain expansion tank and heat exchanger.

3. Remove heat exchanger end covers and remove

core.

4. Clean the inside of exchanger core tubes using

a metal rod. Flush, inspect and clean again if

necessary.

5. Reassemble. Fill the cooling system, start the engine

and check for leaks.

SP17. RAW WATER PUMP

1. Change the seawater pump impeller every 1000

hours, or as needed.

2. Remove the pump end cover. Pry out the impeller

using needle-nose pliers or two screwdrivers.

Be sure you remove all pieces of failed impeller.

NOTE: Place some kind of protection under the

screwdrivers in order not to damage the pump

housing. If the impeller has broken into pieces,

remove front heat exchanger end cover and inspect

for impeller pieces. Clean inlet to heat exchanger

bundle and reassemble.

3. Clean the inside of the housing.

4. Press in the new impeller and place the sealing

washers in the outer end of the impeller center if this

has not already been done.

5. Replace the cover using a new gasket.

NOTE: Make sure that there is always an extra

impeller and cover gasket in reserve on board.

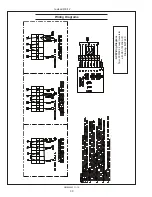

GENERATOR ENDS

The maintenance and operation recommendations

for the generator end are in a separate Owner’s

Manual. If you do not have one of these manuals,

contact your local Northern Lights dealer.

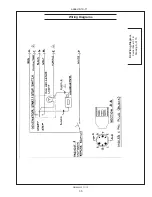

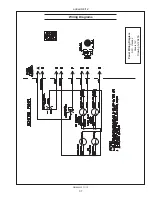

ELECTRICAL SYSTEM - GENERAL

1. Never switch battery switch off or break the circuit

between the alternator and batteries while the engine

is running. Regulator damage can result.

Parts Grains

Contaminates

per Million per Gallon

Maximum Chlorides

40

2.5

Maximum Sulfates

100

5.9

Maximum Dissolved Solids

340

20.0

Maximum Total Hardness

170

10.0

PH Level 5.5 to 9.0

revised 11-8-13

Summary of Contents for M20CRW3

Page 11: ...OM844W3 11 13 9 Notes ...

Page 19: ...OM844W3 11 13 17 Service Record Notes ...

Page 44: ......